Welcome!

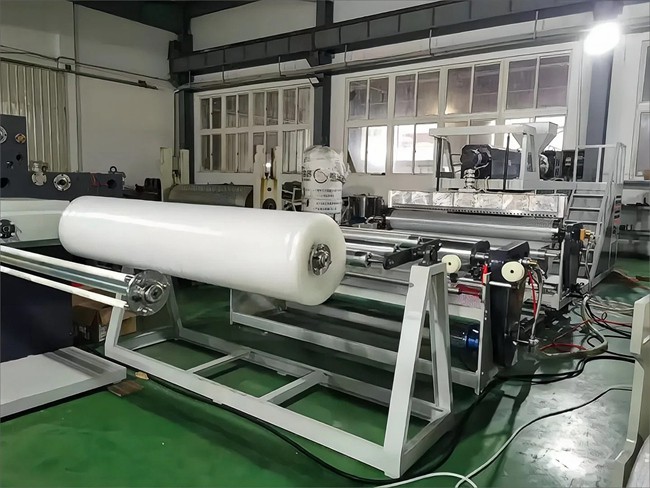

Factory Direct 3-7 Layers Composite Air Bubble Film Making Machine

Product Description

According to the manufacturing method and the method of generating bubbles, bubble wrap machines can be divided into various types, such as manual bubble wrap machines, extrusion bubble wrap machines, and stamping bubble wrap machines.

Manual bubble film machine: requires manual up and down operation, with low production efficiency, but easy to operate, suitable for individuals or small manufacturers to produce low specification bubble films.

Extrusion type bubble film machine: It uses extrusion and stretching methods to produce bubble film, with fast speed and high production efficiency. It is suitable for producing bubble films with large thickness and specifications.

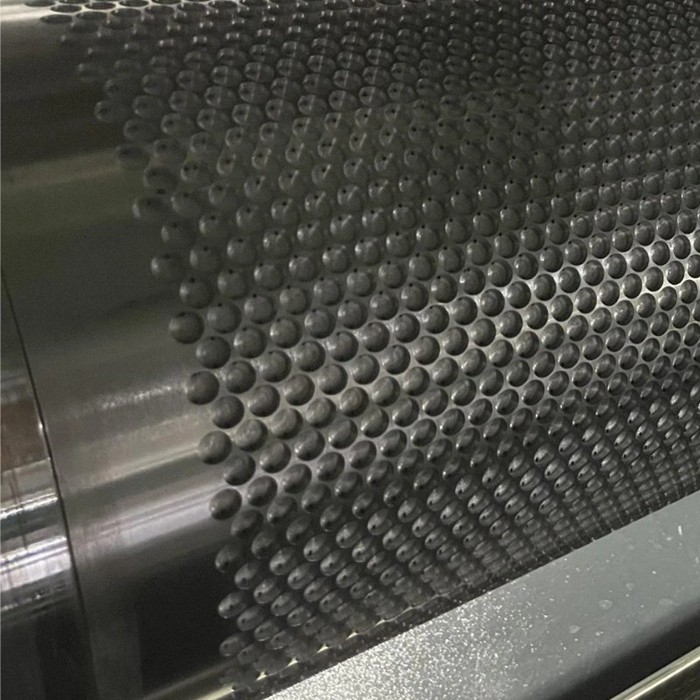

Stamping type bubble film machine: using mold stamping to form bubble film, suitable for producing bubble films of various specifications and shapes.

Working principle: Different types of bubble film machines have different working principles, but overall they process polyethylene and other raw materials into thin films with bubble structures through specific processes.

Although the specific operation may vary depending on the model, overall, the operation of the extrusion bubble film machine is relatively simple and easy to use. Bubble wrap plays an important protective role in logistics transportation, preventing collisions and damage to goods during transportation. In the packaging of electronic products, bubble wrap can effectively protect the outer shell and internal components of the product, preventing damage caused by vibration or impact. Furniture products also require bubble wrap for packaging protection during transportation and storage to prevent scratching and damage.

Recommended Products

Recently Viewed

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Ruian Hualiang Machinery Co.,Ltd.