Welcome!

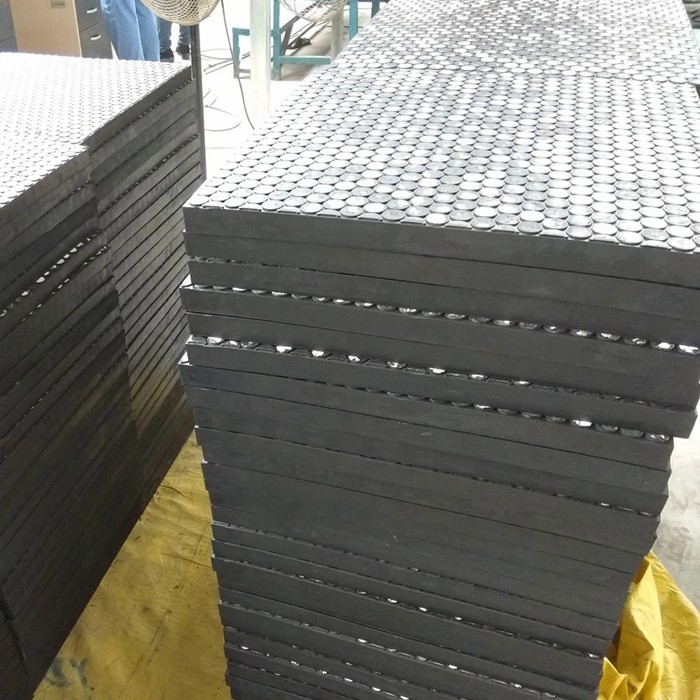

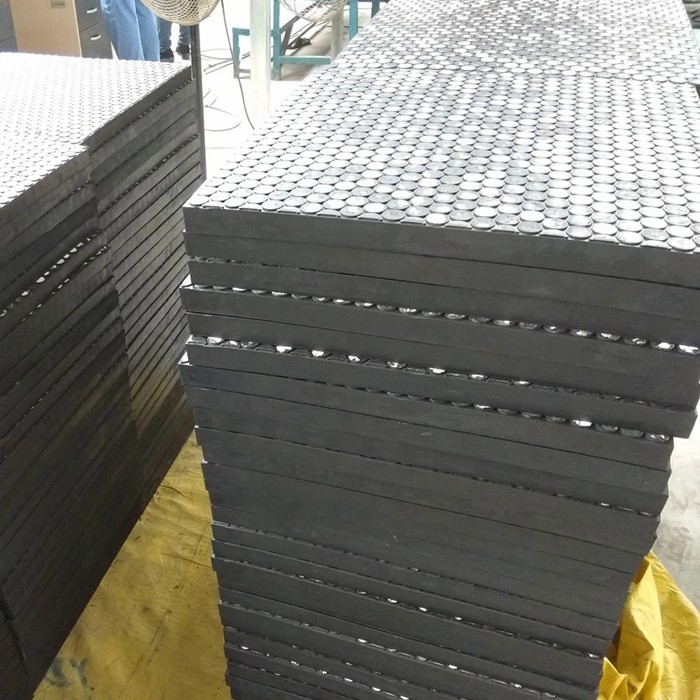

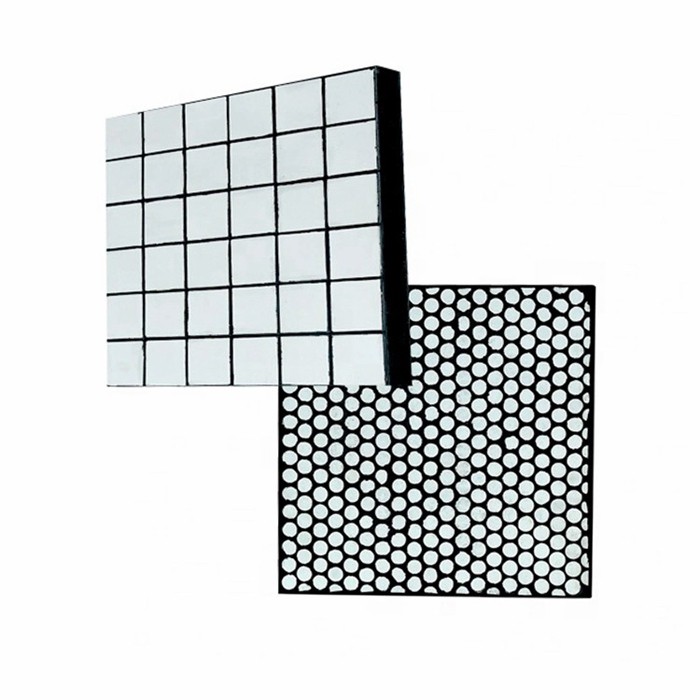

Wholesale Wear Resistant Alumina Ceramic Tile Polyurethane Liner Wear Plates

Product Description

Aluminum oxide wear-resistant ceramic lining plate, with its high hardness and wear resistance, can effectively protect various equipment surfaces from wear and corrosion, thereby extending the service life of equipment. Due to its excellent wear resistance and corrosion resistance, alumina wear-resistant ceramic lining can maintain stable performance under high loads and harsh environments, reducing equipment downtime and maintenance frequency, thereby improving production efficiency.

Alumina ceramic lining plates are widely used in various industries, especially in situations where wear resistance, high temperature resistance, and corrosion resistance are required. Specifically, it can be used as a lining material to protect parts of equipment from wear and corrosion. For example, in the fields of ore, coal mining, casting, etc., alumina ceramic lining plates can be used for lining grinding machines, conveying systems, furnace temperature control systems, etc. In addition, it is widely used in coal transportation, feeding systems, powder production systems, ash discharge, dust removal systems, and other mechanical equipment with high wear and tear in enterprises such as thermal power, steel, smelting, machinery, coal, mining, chemical, cement, and port terminals.

Aluminum oxide ceramic lining plate is mainly made of high-purity aluminum oxide (Al ₂ O3) material, sometimes supplemented with other ingredients as needed. It is a hard and wear-resistant ceramic material made by shaping, sintering, and other processes of alumina powder, with sintering temperatures typically reaching up to 1700 ° C.

Recommended Products

Recently Viewed

Wholesale Alumina Ceramic Steel Impact Rubber Pad Wear Liner Plate

Wholesale Alumina Ceramic Steel Impact Rubber Pad Wear Liner Plate Hot Selling Wear Resistant Alumina Ceramic Tile Polyurethane Liner Wear Plates

Hot Selling Wear Resistant Alumina Ceramic Tile Polyurethane Liner Wear Plates Wholesale Alumina Ceramic Steel Impact Rubber Pad Wear Liner Plate

Wholesale Alumina Ceramic Steel Impact Rubber Pad Wear Liner Plate Wholesale Alumina Oxide Ceramic Liner Plate Wear Resistant Rubber Mat

Wholesale Alumina Oxide Ceramic Liner Plate Wear Resistant Rubber Mat Hot Selling Wear Resistant Alumina Ceramic Tile Polyurethane Liner Wear Plates

Hot Selling Wear Resistant Alumina Ceramic Tile Polyurethane Liner Wear Plates

Contact Us

Zhengzhou Kaiyuan Refractories Co., Ltd.