Welcome!

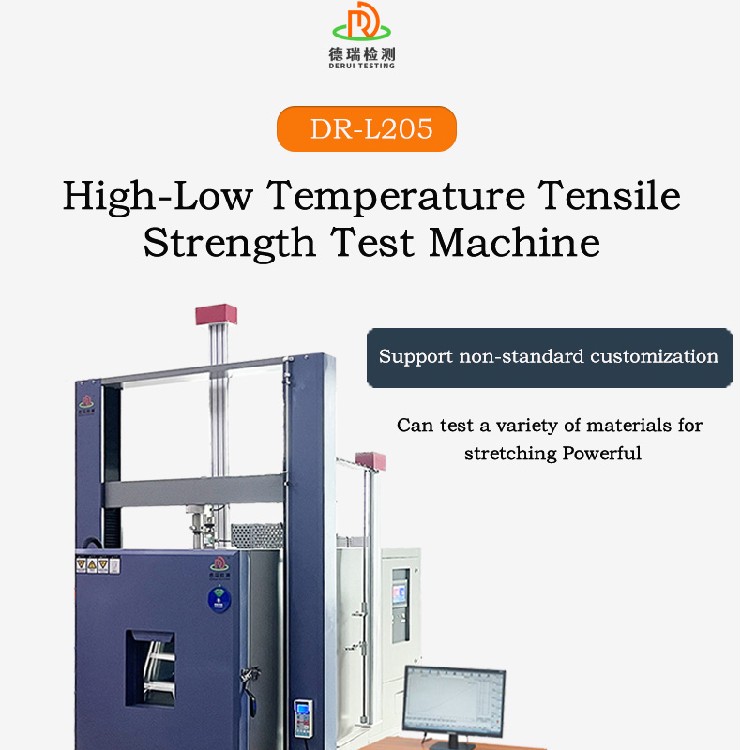

Low temperature tensile strength testing machine

Basic Info

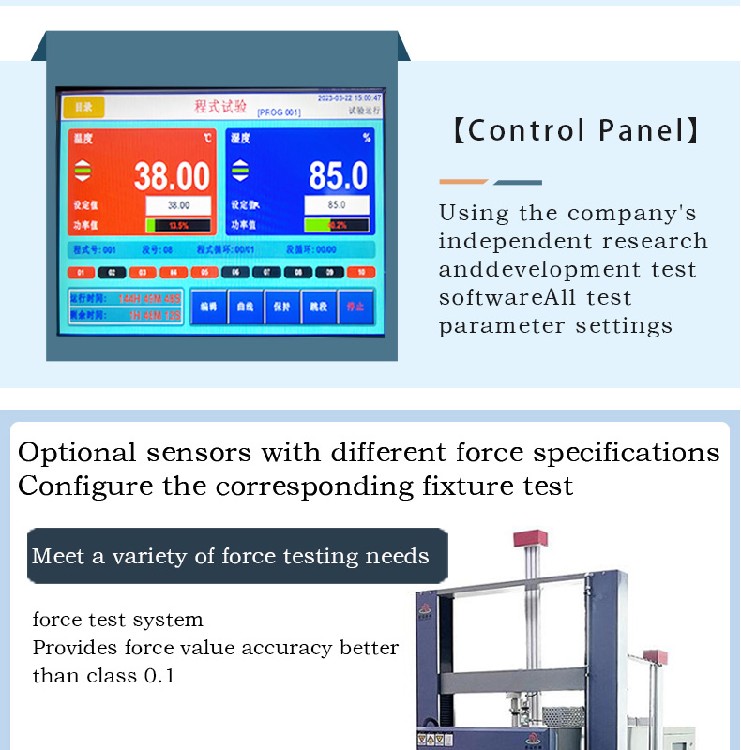

| Control System | Touchscreen with PC interface and software | Load Capacity | 10 kN, 20 kN, 50 kN, 100 kN (customizable) | Load Cell Accuracy | ±0.5% of full scale |

|---|---|---|---|---|---|

| Model | DR-L205 | Specimen Size | Length: 50-250 mm, Width: 10-50 mm | Strain Measurement | Extensometer with 1 μm resolution |

| Temperature Accuracy | ±0.5°C | Temperature Control Method | PID-controlled heating/cooling system | Temperature Range | -40°C to +150°C |

| Test Environment | Controlled atmosphere with temperature chamber | Test Speed | 0.01 mm/min to 500 mm/min | ||

Product Description

A Low Temperature Tensile Strength Testing Machine is a specialized piece of equipment used to evaluate the tensile properties of materials at low temperatures. This type of testing machine is essential for industries where materials must maintain their structural integrity in cold environments, such as aerospace, automotive, construction, and oil and gas. Here’s an overview of this testing machine and its applications across various industries:

Features of a Low Temperature Tensile Strength Testing Machine

- Temperature Control System:Capable of reaching very low temperatures (e.g., down to -196°C or lower) using liquid nitrogen or mechanical refrigeration.Ensures that the sample remains at the desired temperature throughout the test.

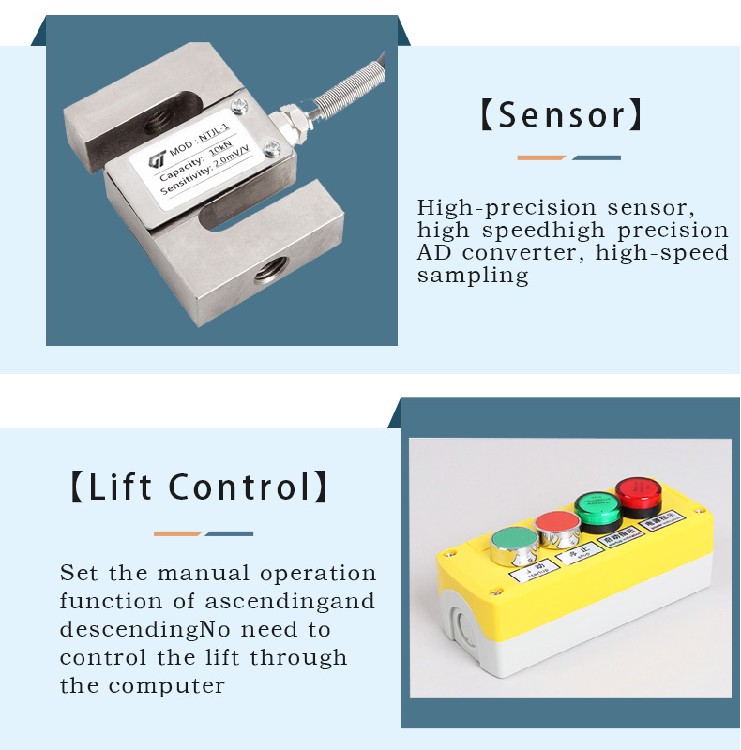

- Tensile Testing Capabilities:Measures the tensile strength, yield strength, elongation, and other mechanical properties of materials under tension.Equipped with load cells to measure force accurately and extensometers to gauge deformation.

- Environmental Chamber:Provides a controlled environment for the material samples during testing.Can be designed for either static or dynamic loading conditions.

- Data Acquisition and Analysis:Integrated software for real-time data collection and analysis.Generates detailed reports on material performance under low-temperature conditions.

- Safety Features:Includes safety interlocks, emergency stop buttons, and protection against cryogenic hazards.Ensures operator safety while handling extremely cold materials.

Applications Across Industries

1. Aerospace

- Application: Evaluating materials used in aircraft structures, engines, and space vehicles that operate in sub-zero conditions.

- Benefit: Ensures materials can withstand the extreme temperatures encountered at high altitudes or in space.

2. Automotive

- Application: Testing components like engine parts, fuel lines, and body panels that may experience freezing temperatures.

- Benefit: Validates the reliability of vehicle components in cold climates, ensuring safe operation.

3. Construction

- Application: Assessing building materials like steel, concrete, and composites that are exposed to cold weather.

- Benefit: Guarantees that structures remain strong and stable even in harsh winter conditions.

4. Oil and Gas

- Application: Testing materials and pipelines that operate in arctic regions or deep-sea environments.

- Benefit: Ensures infrastructure can handle the stresses of low-temperature operations without failure.

5. Medical Devices

- Application: Evaluating materials used in medical devices that might be stored or transported in cold environments.

- Benefit: Confirms that medical equipment maintains its integrity and functionality under varying temperatures.

6. Sports Equipment

- Application: Testing materials used in winter sports gear like skis, snowboards, and ice skates.

- Benefit: Ensures products perform reliably and safely in cold outdoor conditions.

Summary

The Low Temperature Tensile Strength Testing Machine plays a crucial role in assessing how materials behave under extreme cold conditions. By providing precise control over temperature and accurate measurement of tensile properties, it helps ensure that materials and components can function reliably and safely in low-temperature environments. This capability is vital for industries that operate in or design products for cold climates, contributing to improved product quality, safety, and performance.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.