Welcome!

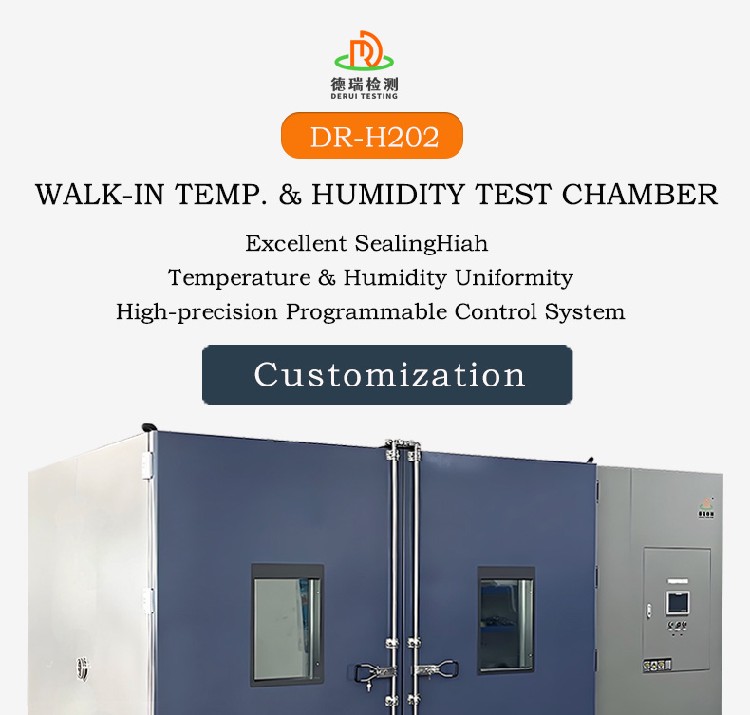

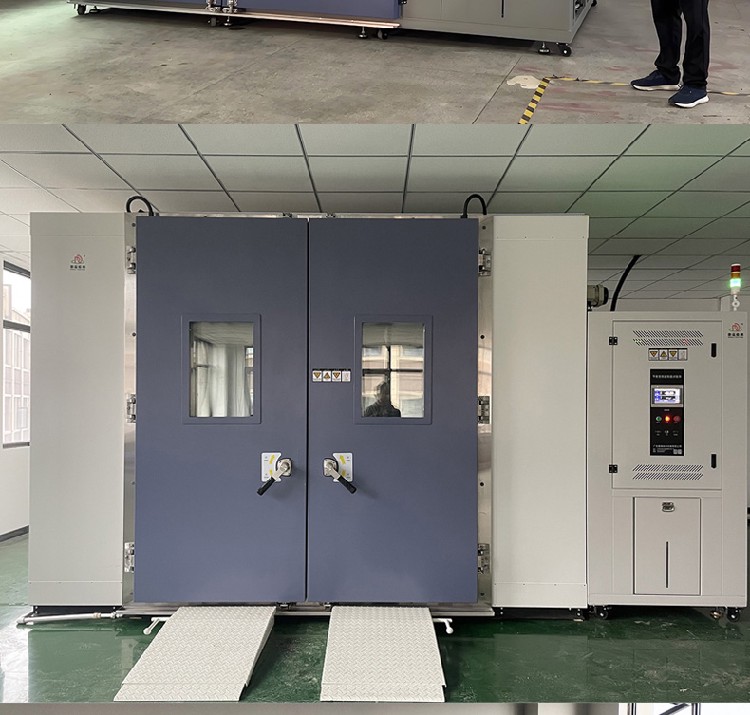

Energy-efficient walk-in high-low temperature test chamber Customized

Basic Info

| Compliance Standards | ISO 9001, IEC 60068-2-1, ASTM D3574 | Data Logging | Built-in data logger with USB export | Environmental Monitoring | Real-time monitoring system |

|---|---|---|---|---|---|

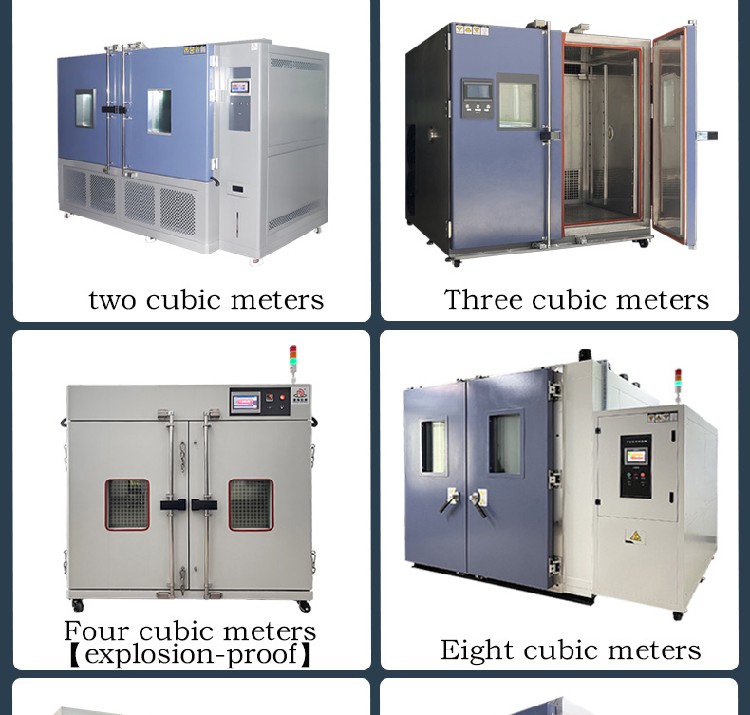

| Model | DR-H202-1 | Test Chamber Volume | 6m³,8m³, 20m³, 30m³ (customizable) | Test Duration | 1 hour to 1000+ hours (customizable) |

| Warranty | 1 tyears | Weight | 2000kg to 5000kg (depending on size) | ||

Product Description

Energy-Efficient Customized Walk-In High-Low Temperature Test Chamber

An Energy-Efficient Customized Walk-In High-Low Temperature Test Chamber is a specially designed environmental chamber used to simulate extreme temperature conditions for large components, systems, or prototypes. The chamber is customized to meet specific testing requirements, offering both high and low temperature ranges while incorporating energy-efficient technologies to reduce operational costs and improve sustainability. These chambers are ideal for industries such as aerospace, automotive, electronics, and defense, where testing large-scale products under rigorous environmental conditions is crucial.

Product Features

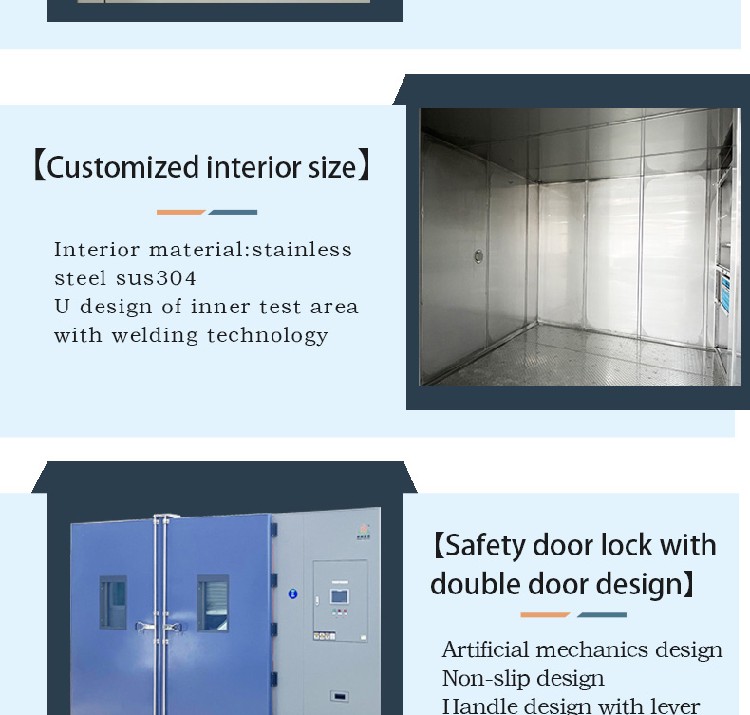

- Customized Size and Configuration:Tailored Dimensions: The chamber can be customized in terms of internal volume, typically ranging from several cubic meters to tens of cubic meters, to accommodate large test specimens like aerospace parts, automotive components, or industrial systems.Flexible Design: You can choose specific configurations for access points, such as large walk-in doors, side doors, windows, or custom racks for holding test samples.Multiple Test Zones: Customizable multi-zone temperature control can be incorporated into the chamber to create separate areas with different temperature conditions, allowing simultaneous testing of different products or components.

- Energy-Efficient Temperature Control:Wide Temperature Range: These chambers are designed to operate efficiently across a wide temperature range, typically -70°C to +180°C or even -100°C to +250°C, with fast cooling and heating capabilities.Efficient Cooling and Heating Systems: Incorporates high-efficiency compressors, heat exchangers, and variable speed fans to minimize energy usage while maintaining precise temperature control.Advanced Insulation: The chamber features high-quality, thick insulation materials (e.g., polyurethane foam, rock wool) to reduce heat loss and improve energy efficiency, enabling the chamber to maintain internal temperatures using less energy.

- Optimized Airflow and Temperature Distribution:Improved Air Circulation: Designed with forced-air circulation systems to ensure uniform temperature distribution throughout the chamber, preventing temperature gradients that could affect test results.Even Temperature Uniformity: The chamber’s interior is optimized to achieve minimal temperature variation (typically within ±2°C), crucial for accurate and repeatable testing, especially for large samples.Customizable Airflow Patterns: In larger chambers, airflow can be customized based on the test requirements, such as vertical or horizontal airflow to optimize testing conditions for specific components.

- Precise Temperature and Humidity Control (Optional):If your testing requires both temperature and humidity control, the chamber can be equipped with a humidity control system that maintains precise high humidity (85%-98% RH) and low humidity conditions.Dehumidification Systems: The dehumidification system is designed to operate energy-efficiently, providing stable humidity levels with reduced energy consumption.

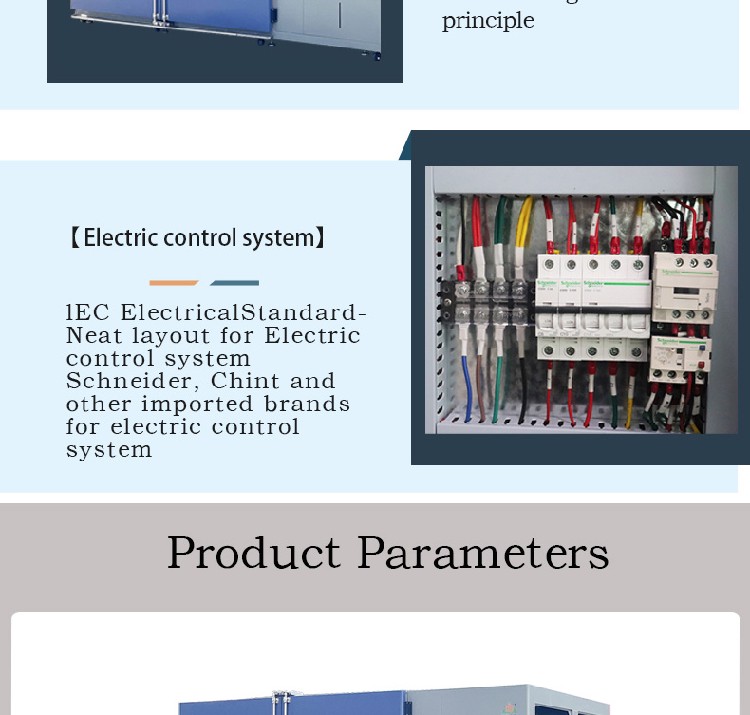

- Custom Control Systems:Advanced Control Panel: A user-friendly touchscreen interface for easy setup and monitoring of temperature, humidity, and other test parameters. It can also include programmable profiles for automated testing, such as temperature ramps, hold times, and cycling patterns.Remote Monitoring: Many modern chambers offer remote control capabilities, enabling you to monitor and control the system from outside the chamber through Wi-Fi or Ethernet connections.Energy Consumption Monitoring: Integrated features to track energy usage, providing valuable insights into how the chamber’s energy consumption fluctuates based on different test cycles.

- Eco-Friendly Refrigerant Systems:The chamber is designed to use eco-friendly refrigerants, such as R-290 (propane) or R-32, which have lower global warming potential (GWP) and ozone depletion potential (ODP) compared to traditional refrigerants like R-404A or R-134a.Efficient Heat Recovery: Some models may include heat recovery systems that use the excess heat generated during cooling to preheat the incoming air, further reducing energy consumption.

- Advanced Safety Features:Over-temperature and Over-pressure Protection: These systems automatically shut down or trigger alarms in case of abnormal temperature or pressure conditions, ensuring the safety of the chamber and test samples.Automatic Door Seals: Designed with high-quality seals and gaskets to prevent temperature loss and improve chamber efficiency while ensuring a tight seal during tests.

Product Characteristics

- Customizable to Specific Testing Needs:A key feature of the energy-efficient walk-in chamber is its customization capability. It can be tailored to fit the precise size, configuration, and temperature range required for your unique testing needs. Whether for aerospace testing, automotive parts, or industrial machinery, this flexibility allows you to test a wide variety of products.

- Sustainable and Eco-Conscious Design:By incorporating high-efficiency components and using eco-friendly refrigerants, these chambers support your company's sustainability goals. Reduced energy consumption, combined with high-performance insulation and optimized cooling/heating systems, minimizes the chamber's environmental impact.

- Optimized for Long-Term Use:These chambers are built for durability and high-frequency use. The construction uses stainless steel or anti-corrosive materials to withstand long-term exposure to extreme conditions, ensuring the chamber performs consistently for many years.

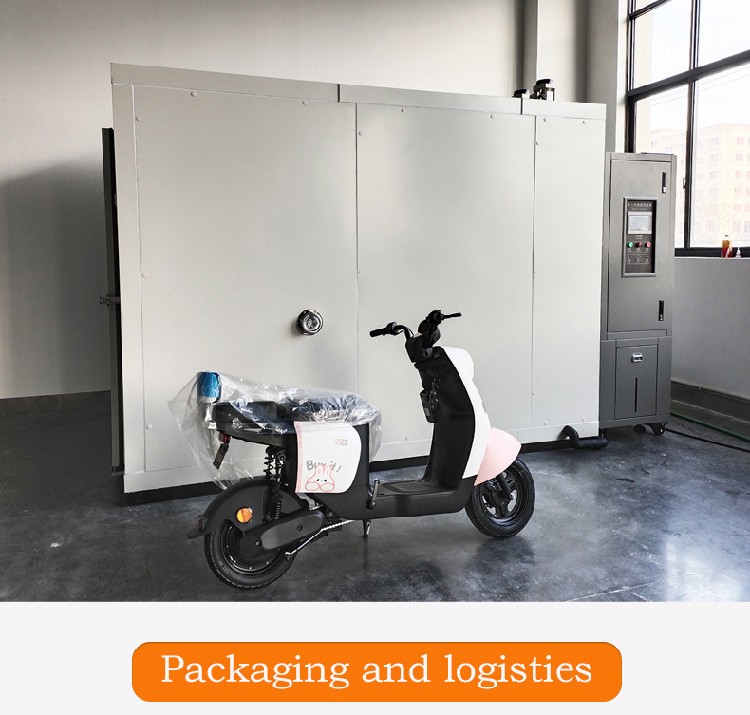

- Suitable for Large-Scale Testing:With their large interior volume, walk-in chambers provide ample space for testing bulky or oversized products, making them ideal for industries that require full-scale testing of prototypes or large components. The chamber’s size and adaptability also allow for testing multiple smaller samples simultaneously.

Usage Guidelines

- Sample Preparation:Before placing test samples in the chamber, ensure they are clean, dry, and properly mounted to allow for uniform exposure to the environmental conditions.If your samples are large or heavy, ensure that they are securely placed in the chamber to avoid shifting during the test cycle, which could affect the test results.

- Test Setup:Program the temperature cycle according to the specifications of the test. Set temperature ramp rates, hold times, and cycling patterns as needed. Most chambers allow users to create detailed test programs.If humidity is also being controlled, ensure that the humidity levels are set correctly and monitored throughout the test.

- Monitoring During Test:Continuously monitor the test environment through the control panel or remote monitoring system. Ensure that the chamber is operating within the set parameters for temperature, humidity, and airflow.Make adjustments to the test cycle if needed based on real-time data or alerts triggered by the chamber’s control system.

- Data Logging:Use the built-in data logging system to record critical data such as temperature, humidity, and other environmental parameters during the test. This data will help you evaluate product performance and identify points of failure or areas for improvement.

- Maintenance:Regularly inspect the chamber to ensure optimal performance. Clean the filters, check the seals, and inspect the compressor and fans to maintain the energy-efficient operation of the system.Perform periodic calibration of the temperature and humidity sensors to ensure measurement accuracy.

Installation Environment

- Space Requirements:Ensure that the chamber has enough space for installation, including clearance for doors and proper airflow around the unit. This space also provides room for maintenance access.The room in which the chamber is installed should be large enough to accommodate its dimensions, including ventilation and emergency access.

- Power Supply:The chamber requires a stable power supply (usually three-phase 380V/480V), and it is important to ensure the installation site can support the electrical demand.The chamber may also require dedicated circuit breakers or isolation transformers, depending on its power rating and local regulations.

- Ventilation:Ensure the installation area has adequate ventilation to help maintain optimal operating temperatures for the chamber’s cooling and heating systems.The exhaust air from the chamber should not be directed toward sensitive equipment or other areas of the facility.

- Ambient Temperature:The room should maintain an ambient temperature between 15°C and 25°C to ensure the chamber’s internal systems, especially the cooling system, work efficiently.

Conclusion

An Energy-Efficient Customized Walk-In High-Low Temperature Test Chamber offers a tailored solution for testing large products or components under extreme temperature conditions. It combines high-performance temperature control with sustainability features to reduce energy consumption, ensuring both accurate testing and cost efficiency. Customizable to your specific needs, this chamber is ideal for industries that require rigorous environmental testing and durability evaluations for oversized or complex products. By optimizing both performance and energy use, these chambers provide a robust, reliable, and eco-friendly testing solution.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.