Welcome!

The following is the customization process for sand and dust test chambers, including specific steps and precautions: Customization process Demand communication: Communicate in detail with the supplier to clarify the customization requirements, such as the size of the test chamber, temperature range, humidity range, sand and dust type, control function, etc.. Provide specific test standards and application scenarios, so that the supplier can design a suitable program. Program design: Suppliers design customized solutions according to user requirements, including the structure of the equipment, materials, control systems and so on. Provide detailed technical parameters and equipment layout diagrams to ensure that the program meets all user requirements. Quotation confirmation: Suppliers provide quotations according to the design, including equipment costs, manufacturing costs, transportation costs and so on. The user confirms the quotation and negotiates the payment method and delivery time. Contract signing: After both parties agree on the customized content, price, delivery time, after-sales service and other terms, sign a formal contract. The contract should clarify the responsibilities and obligations of both parties to ensure that the customization process goes smoothly. Manufacturing: The supplier starts to produce and manufacture the customized sand and dust test chamber, processing and assembling according to the design scheme and standards. During the production process, the user can regularly learn about the production progress to ensure that the equipment is completed on time. Quality Testing: After the production is completed, the supplier carries out strict quality testing and calibration of the equipment to ensure that the various performance indicators of the equipment meet the standard requirements. The test includes temperature control accuracy, humidity control range, uniformity of sand and dust concentration, wind speed adjustment ability and so on. Installation and commissioning: Deliver the customized sand dust test chamber to the user, and be responsible for the installation and commissioning to ensure that the equipment operates normally at the user's site. During the commissioning process, the supplier should assist the user to solve the technical problems that may arise. Training and after-sales: The supplier provides users with operation training, including the basic operation of the equipment, parameter settings, daily maintenance and other content. Provide perfect after-sales service, such as equipment warranty, technical advice, supply of accessories, etc., to ensure that the user has no worries in the process of use. Precautions Clarify requirements: Before customization, users should clarify their own testing requirements and standards to avoid repeated modifications and delays caused by unclear requirements. Choose professional suppliers: Choose suppliers with good reputation and rich experience to ensure the quality and performance of the equipment. Attention to details: In the design program and contract, attention should be paid to the detailed requirements of the equipment, such as the quality of materials, control system stability, and safety protection measures. Strict testing: Before the equipment is delivered, users should participate in the final quality testing to ensure that the equipment meets the expected requirements. for LED Lighting and Consumer Electronics

Product Description

Dust Test Chamber Parameter

Item | Specification |

| Internal dimension | 800W*800D*800Hmm |

| External dimension | 1300W*1000D*1700Hmm |

| Test sample | Size W20cm- L30cm-D15cm, weight 0.5kg |

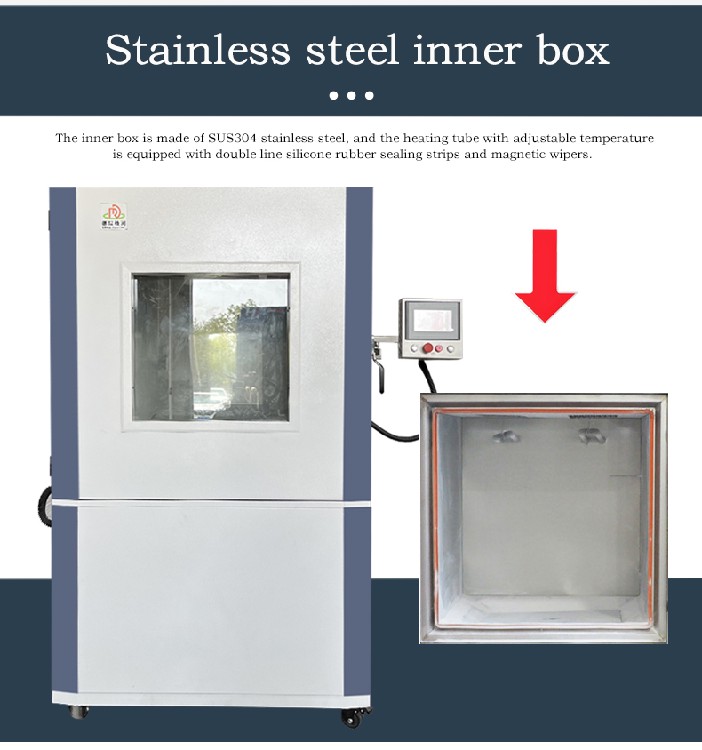

| Chamber material | SUS304 Stainless steel |

| Specifications of square mesh sieve | Mesh hole 75um, mesh metal wire diameter 50um |

| Talcum powder amount | 2kg/ m³ |

| Airflow speed | No more than 2m/s |

| Door | Left open door with tempered glass door |

| Controller | PLC Touch Screen controller, programmable to set as below cycle:a. Blowing dust time (Stop/Blow) m/sb. Cycle time: can be adjustedc. Pre-set test time: 0s ~99m99s |

| Vacuum system | Pressure gauge, air filter, Pressure regulating FRL, connecting pipe, Vacuum pump |

| Vacuum pump capacity | 60-600 L/H |

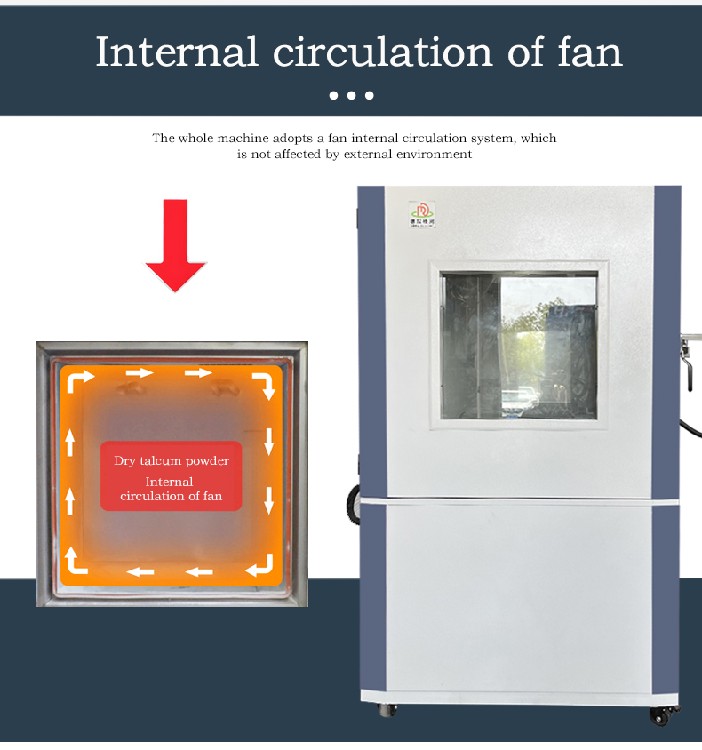

| Fan | Centrifugal fan |

| Safety protection devices | Meter over-temperature function, Phase shortage protection, Power short-circuit protection |

The following is the customization process for sand and dust test chambers, including specific steps and precautions:

Customization process

Demand communication:

Communicate in detail with the supplier to clarify the customization requirements, such as the size of the test chamber, temperature range, humidity range, sand and dust type, control function, etc..

Provide specific test standards and application scenarios, so that the supplier can design a suitable program.

Program design:

Suppliers design customized solutions according to user requirements, including the structure of the equipment, materials, control systems and so on.

Provide detailed technical parameters and equipment layout diagrams to ensure that the program meets all user requirements.

Quotation confirmation:

Suppliers provide quotations according to the design, including equipment costs, manufacturing costs, transportation costs and so on.

The user confirms the quotation and negotiates the payment method and delivery time.

Contract signing:

After both parties agree on the customized content, price, delivery time, after-sales service and other terms, sign a formal contract.

The contract should clarify the responsibilities and obligations of both parties to ensure that the customization process goes smoothly.

Manufacturing:

The supplier starts to produce and manufacture the customized sand and dust test chamber, processing and assembling according to the design scheme and standards.

During the production process, the user can regularly learn about the production progress to ensure that the equipment is completed on time.

Quality Testing:

After the production is completed, the supplier carries out strict quality testing and calibration of the equipment to ensure that the various performance indicators of the equipment meet the standard requirements.

The test includes temperature control accuracy, humidity control range, uniformity of sand and dust concentration, wind speed adjustment ability and so on.

Installation and commissioning:

Deliver the customized sand dust test chamber to the user, and be responsible for the installation and commissioning to ensure that the equipment operates normally at the user's site.

During the commissioning process, the supplier should assist the user to solve the technical problems that may arise.

Training and after-sales:

The supplier provides users with operation training, including the basic operation of the equipment, parameter settings, daily maintenance and other content.

Provide perfect after-sales service, such as equipment warranty, technical advice, supply of accessories, etc., to ensure that the user has no worries in the process of use.

Precautions

Clarify requirements: Before customization, users should clarify their own testing requirements and standards to avoid repeated modifications and delays caused by unclear requirements.

Choose professional suppliers: Choose suppliers with good reputation and rich experience to ensure the quality and performance of the equipment.

Attention to details: In the design program and contract, attention should be paid to the detailed requirements of the equipment, such as the quality of materials, control system stability, and safety protection measures.

Strict testing: Before the equipment is delivered, users should participate in the final quality testing to ensure that the equipment meets the expected requirements.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.