Welcome!

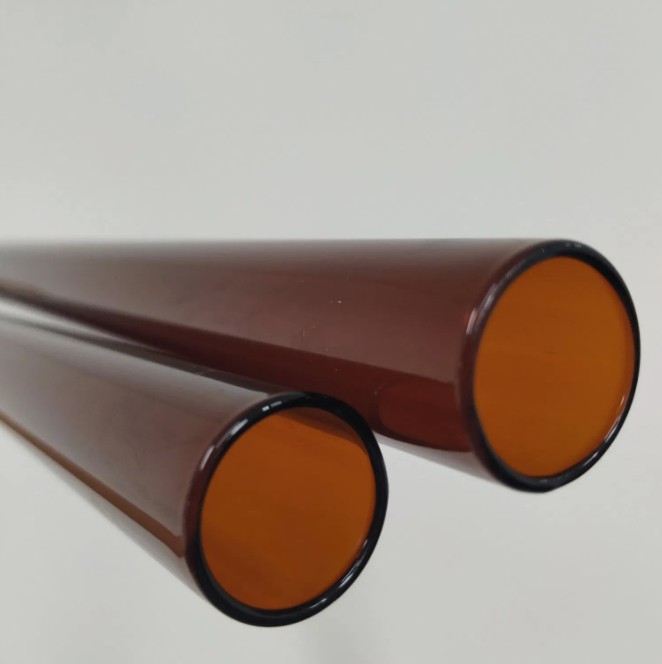

Customizable logo Laboratory glass test tubes

Basic Info

| Capacity | All specifications | Catalogue | Available | Certificate | FDA, CE, ISO, FSC, GMP |

|---|---|---|---|---|---|

| Color | Transparent | Delivery date | About 15-30 Days | Graduation | With or Without |

| HS Code | 3917290000 | Individually Packing | PE Bag | Logo | Accept Customize |

| Material | PP, PS, PE, Glass | Model NO. | JLY-TT-001 | OEM | Provide |

| Sample | Free | Shelf life | 5 Years | Transport Package | Corrugated Carton |

| Tube Cap | With or Without | Type | Ordinary Test Tube | Use | Laboratory |

Product Description

Laboratory glass test tubes are essential tools in scientific research, chemical analysis, and medical diagnostics. Designed to hold, mix, or heat small quantities of substances, these cylindrical vessels are a cornerstone of experimental workflows. Below is an overview of their production process, key characteristics, applications, and quality standards.

Production Process

1. Material Selection: Renowned for its low thermal expansion and high resistance to thermal shock and chemical corrosion, most laboratory test tubes are made from borosilicate glass (e.g., Pyrex®). Raw materials include silica sand, boron trioxide, and alkali oxides.

2. Melting and Molding: The raw materials are melted at temperatures exceeding 1,600°C in a furnace. Then the molten glass is blown or molded into cylindrical shapes using automated machinery or traditional glassblowing techniques.

3. Annealing: To relieve internal stresses, the tubes undergo a controlled cooling process (annealing) in a lehr oven, ensuring durability and structural integrity.

4. Finishing: The open end is polished for smoothness, and some tubes are fire-polished to create a rounded rim. Graduations or labels may be added via etching or heat-resistant inks.

5. Quality Inspection: Each tube is inspected for defects like bubbles, cracks, or uneven thickness.

Advantage

Thermal Resistance: Borosilicate glass withstands extreme temperatures (up to 500°C), making test tubes suitable for heating over Bunsen burners or in autoclaves.

Chemical Inertness: Resist acids, alkalis, and organic solvents, ensuring minimal interaction with reactive substances.

Transparency: Allow clear visual observation of reactions or samples.

Reusability: Can be sterilized and reused repeatedly, reducing waste.

Versatile Sizes: Available in various lengths (e.g., 75–150 mm) and diameters with or without lips for easy pouring.

Applications

Chemical Reactions: Mixing or heating reagents in qualitative or quantitative analysis.

Biological Studies: Culturing microorganisms or storing samples (e.g., blood, DNA).

Medical Diagnostics: Centrifuging blood samples or conducting urinalysis.

Educational Labs: Fundamental tools for teaching basic chemistry and biology.

Quality Standards

Laboratory glass test tubes must comply with international standards such as ASTM E438 (for glass types) and ISO 3585 (borosilicate specifications). Reputable manufacturers ensure:

Consistent wall thickness and dimensions.

Sterility for medical-grade tubes.

Accurate volume graduations (if present).

About Us

Yangzhou Huiying Glass Crafts Co., Ltd. is a professional engaged in the production of glass products at home and abroad enterprise. Mainly processing control glassproducts and heat-resistant glass bottle is given priority to aregular control bottle, cosmetic bottle, medicinal bottle, perfume bottle, glass tube, glass dropper and glass bottle printing. We also produce special gauge glass bottle production, and have a variety of supporting facilities required for production.

Under the two big shop:

1. Vertical workshop: Medicinal bottle, cosmetic bottle, perfume bottles, etc.

2. Horizontal type workshop: Glass dropper, tube, glassprinting, ect.

Our plant adheres to the " people-oriented, good faithdevelopment " business philosophy, and quickly opens the market at home and abroad with strict management, excellent quality.

Welcome new and old customers to cooperate with our exquisite products and service to attract you! Touch you!

Recommended Products

Recently Viewed

Contact Us

Yangzhou Huiying Glass Crafts Co., Ltd.