Welcome!

Labelers: Automated Precision for Modern Industries

Basic Info

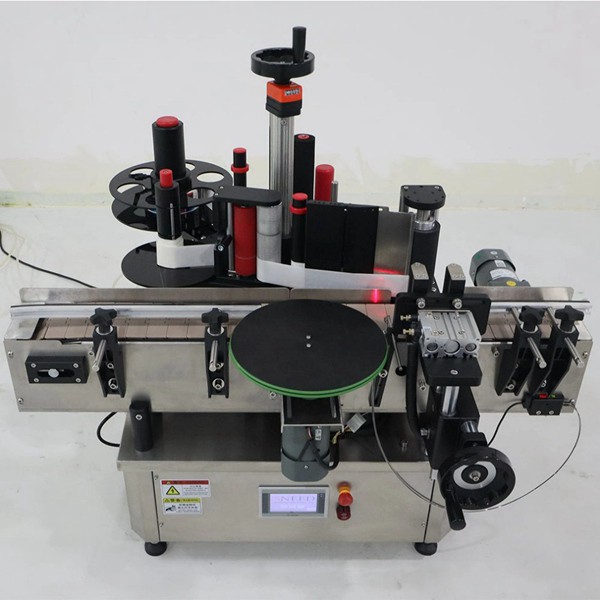

| Applicable Industry | Beverage | Application | Drinks | Automatic Grade | Automatic |

|---|---|---|---|---|---|

| Classification | Automatic Vertical Round Bottle Labeling Machine | Driven Type | Electric | Hot Glue Labeling | Hot Glue Labeler |

| Hot Glue Labeling Machine | Hot Melting Glue Labeling | Hot Melt Glue Labeler | Hot Melting Glue Machine | Model NO. | Hot Melt Glue Labeler |

| Origin | China | Package Gross Weight | 2200.000kg | Package Size | 1800.00cm * 2760.00cm * 2950.00cm |

| Production Capacity | 10 Sets/Month | Specification | CE, ISO, UL | Transport Package | Film Wrapping Plus Wooden Case |

| Type | Hot Melt Adhesive Labeling Machine | ||||

Product Description

Product Introduction

Labelers are advanced automated systems designed to streamline labeling processes across industries, offering precision, speed, and reliability. These machines are engineered to apply labels seamlessly to products, packaging, or components, ensuring consistency and compliance with industry standards. Ideal for manufacturing, logistics, food and beverage, pharmaceuticals, and retail sectors, Labelers eliminate manual errors and enhance operational efficiency.

Equipped with customizable settings, Labelers accommodate various label sizes, shapes, and materials from adhesive stickers to RFID tags. Their intuitive interfaces allow operators to program labeling patterns, adjust placement accuracy, and integrate with existing production lines or standalone workflows. Whether handling high-speed bulk labeling or delicate item-specific applications, Labelers deliver flawless results while minimizing waste.

Key Advantages of Labelers

1. Enhanced Productivity

- High-Speed Operation: Labelers process hundreds to thousands of items per hour, outpacing manual labeling significantly.

- 24/7 Reliability: Built for continuous operation, they reduce downtime and maximize output in fast-paced environments.

2. Precision and Consistency

- Laser-Guided Accuracy: Advanced sensors and alignment systems ensure that labels are applied uniformly even on curved or irregular surfaces.

- Error Reduction: Automated systems eliminate human mistakes, ensuring compliance with regulatory and branding requirements.

3. Versatility

- Multi-Format Compatibility: Adaptable to diverse label types (roll-fed, pre-cut, shrink sleeves) and container shapes (bottles, boxes, pouches).

- Quick Changeover: Modular designs enable rapid adjustments for different product lines, reducing setup time.

4. Cost Efficiency

- Material Savings: Precise label placement minimizes misprints and adhesive waste.

- Low Maintenance: Durable components and self-diagnostic tools reduce long-term operational costs.

5. User-Friendly Design

- Touchscreen Controls: Intuitive interfaces simplify programming and real-time monitoring.

- Scalability: Upgradeable software and hardware support evolving business needs.

6. Sustainability

- Energy-Efficient Operation: Optimized power consumption aligns with eco-friendly initiatives.

- Reduced Waste: Precision application lowers label and adhesive usage, supporting sustainable practices.

Applications

Labelers are ideal for:

1. Product branding and batch coding.

2. Compliance labeling (expiry dates, barcodes, safety warnings).

3. Inventory management and traceability.

Why Choose Us?

Guangzhou Change Machinery Co., Ltd. is a dynamic and innovative machinery manufacturing enterprise headquartered in Guangzhou, China, specializing in the design, production, and distribution of high-performance equipment for industries such as mining, construction, metallurgy, and chemical processing. With a steadfast commitment to technological excellence and customer-centric solutions, the company integrates advanced manufacturing techniques, rigorous quality control systems compliant with international standards, and a seasoned R&D team to deliver durable, efficient, and customized machinery tailored to global clients' evolving needs. Renowned for its reliable after-sales support and sustainable practices, Guangzhou Change Machinery has established a robust reputation for empowering industrial productivity while fostering long-term partnerships worldwide.

Conclusion

Labelers revolutionize labeling workflows by combining cutting-edge technology with operational flexibility. By automating repetitive tasks, they empower businesses to achieve higher accuracy, faster throughput, and cost savings while meeting stringent quality standards. Whether for small-scale operations or large industrial setups, Labelers are a cornerstone of modern and efficient production ecosystems. Invest in Labelers to future-proof your labeling processes and stay ahead in a competitive market.

Recommended Products

Recently Viewed

Unlock the Power of Labelers: Enhance Efficiency and Precision in Every Task

Unlock the Power of Labelers: Enhance Efficiency and Precision in Every Task Enhancing Efficiency with Labelers: A Comprehensive Guide

Enhancing Efficiency with Labelers: A Comprehensive Guide The Perfect Fit: A Deep Dive into Automated Glass Bottle Labeling Machines

The Perfect Fit: A Deep Dive into Automated Glass Bottle Labeling Machines The Unseen Engine of Modern Packaging: A Comprehensive Guide to Labeling Machines

The Unseen Engine of Modern Packaging: A Comprehensive Guide to Labeling Machines How Automated Labeling Systems Revolutionize Modern Operations

How Automated Labeling Systems Revolutionize Modern Operations

Contact Us

Guangzhou Change Machinery Co., Ltd.