Welcome!

The Perfect Fit: A Deep Dive into Automated Glass Bottle Labeling Machines

Basic Info

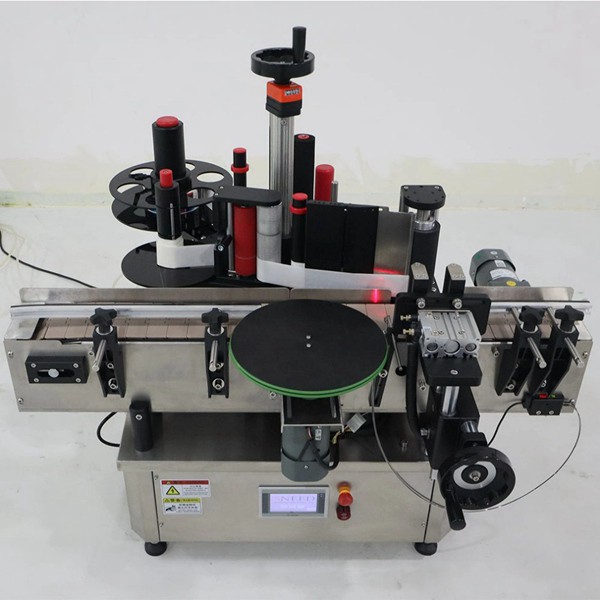

| Application | Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Oil, Tea, Snack, Dairy Products | Automatic Grade | Automatic | Driven Type | Electric |

|---|---|---|---|---|---|

| HS Code | 842230 | Labeling Accuracy | 1mm | Labeling Speed | 40-200b/Min |

| Max Power Supply | 1.2kw | Origin | China | Power Supply | AC220V 50/60Hz |

| Transport Package | Wooden Case | ||||

Product Description

In the world of packaging, few challenges are as specific and demanding as labeling glass bottles. The combination of a rigid, often slippery surface, potential for condensation, and the high aesthetic standards of industries like beverages, cosmetics, and pharmaceuticals demands a specialized solution. Enter the automated glass bottle labeling machine: a pinnacle of engineering designed not just to apply a label, but to enhance brand integrity, accelerate production, and ensure unwavering consistency. This comprehensive guide explores how these specialized systems conquer the unique challenges of glass, turning a complex task into a seamless, efficient, and reliable process.

Understanding the Specialized Role of a Glass Bottle Labeler

An automated glass bottle labeling machine is a precision apparatus dedicated to applying labels to glass containers with exceptional accuracy and speed. Unlike generic labeling systems, these machines are engineered to handle the specific physical characteristics of glass, such as its non-porous surface, round or irregular shapes, and susceptibility to breakage. They are integral components in high-speed production lines for products like craft beer, wine, spirits, sauces, premium juices, perfumes, and pharmaceuticals. Their core function extends beyond simple application; they ensure that every label is a perfect ambassador for the brand, applied smoothly, securely, and without flaws that could detract from the product's perceived value.

Key Engineering Features for Flawless Performance on Glass

The effectiveness of a glass bottle labeling machine lies in its tailored features, each addressing a specific challenge associated with the material.

Precision Container Handling: Stability is paramount. These systems often incorporate specially designed guides, gripper belts, or star wheels that securely transport bottles of varying diameters without causing jams or scratches. This gentle yet firm handling prevents tipping and ensures consistent positioning for the label application point.

Advanced Application Mechanisms for Challenging Surfaces: Given the non-absorbent nature of glass, adhesive activation and application are critical. High-performance machines utilize mechanisms like wipe-on brushes or rollers that apply firm, even pressure to press the label onto the bottle, eliminating air bubbles and ensuring immediate adhesion. For wet conditions, such as labeling chilled beverages, systems are designed to manage moisture effectively.

Sophisticated Label Control Systems: The machine precisely manages the label itself, from dispensing it from the backing liner to applying the correct amount of adhesive (if not using pre-glued labels). Sensors detect the exact position of each bottle, triggering the applicator head at the perfect moment to place the front, back, and neck labels with millimeter accuracy.

Robust Construction and Hygienic Design: Built for demanding environments, these labelers often feature stainless steel or anodized aluminum frames that resist corrosion, especially important in wet or wash-down conditions common in food and beverage production. Their design prioritizes easy cleaning and maintenance to meet strict hygiene standards.

Flexible Changeover Capabilities: Modern bottling lines often run multiple products. Advanced machines allow for quick changeovers between different bottle sizes and label shapes. Digital interfaces store preset configurations, enabling operators to switch from, for example, a wine bottle to a round spirit bottle with minimal downtime.

The Compelling Advantages for Your Bottling Operation

Integrating a specialized glass bottle labeler delivers measurable benefits that impact both the bottom line and brand reputation.

Uncompromising Label Quality and Aesthetic Appeal: The primary advantage is the flawless finish. By eliminating human error, these machines ensure every label is straight, smooth, and free of wrinkles or bubbles. This perfection is crucial for premium products where the package is a key part of the consumer experience, directly influencing purchasing decisions.

Dramatic Increase in Production Line Speed: Automation unlocks new levels of throughput. Capable of applying hundreds of labels per minute, these systems keep pace with high-speed filling and capping equipment, eliminating labeling as a bottleneck and significantly increasing overall line output.

Significant Reduction in Material Waste and Labor Costs: Manual labeling is prone to errors that result in wasted labels and rejected products. Automation virtually eliminates this waste. Furthermore, it reduces reliance on manual labor for a repetitive task, freeing up staff for quality control and more skilled functions, leading to substantial long-term savings.

Enhanced Compliance and Traceability: For regulated industries, particularly pharmaceuticals and food and beverage, accurate labeling is non-negotiable. Automated systems ensure that critical information like batch numbers, ingredients, and expiration dates are applied correctly and legibly every time, simplifying compliance and audit trails.

Primary Applications Across Industries

The precision of glass bottle labeling machines makes them essential in several key sectors.

Beverage Industry: This is the most prominent application. From applying body and neck labels on craft beer bottles to front-and-back labels on premium olive oil and wine bottles, these machines handle high volumes while maintaining a pristine appearance that is vital for shelf appeal.

Cosmetics and Perfumery: In the luxury segment, presentation is everything. Labeling machines ensure that delicate, often intricate labels are applied perfectly to perfume bottles, lotion containers, and serum droppers, enhancing the product's luxurious feel.

Food and Condiments: Glass jars and bottles for sauces, dressings, and specialty foods require durable, clear labeling. Automated systems provide the speed and reliability needed for large-scale production in these markets.

Pharmaceuticals and Chemicals: Accuracy and legibility are critical for safety. These machines reliably apply labels with dosage instructions, warnings, and chemical compositions to medicine bottles and laboratory containers, ensuring patient and user safety.

Frequently Asked Questions About Glass Bottle Labeling Machines

Q1: Can these machines handle different shapes of glass bottles, like square or oval?

A1: Yes, modern machines are highly adaptable. With customizable guides and programmable application settings, they can be configured to handle a wide variety of shapes, including round, square, oval, and even custom-designed bottles, ensuring precise label placement on each.

Q2: What types of adhesives are used, and how do they ensure the label stays on?

A2: The machines are compatible with various adhesive types, including permanent, removable, and water-resistant formulations. The combination of the correct adhesive for the product's environment (e.g., chilled or room temperature) and the machine's precise application pressure ensures a strong, lasting bond with the glass surface.

Q3: Is it possible to apply multiple labels to one bottle, such as a front, back, and neck label?

A3: Absolutely. Many systems are designed as multi-purpose labelers, capable of applying several labels to a single bottle in one pass. This is achieved through multiple labeling stations integrated into one conveyor system, which is a standard requirement in the beverage industry.

Q4: How does the machine handle bottles that are wet or cold from a pasteurizer or cooler?

A4: This is a common challenge that specialized machines are built to overcome. They use adhesives designed to adhere to cold, damp surfaces and may feature application mechanisms that effectively displace water during the labeling process to ensure a secure bond.

Q5: What is the typical maintenance routine for these machines?

A5: Routine maintenance is crucial for longevity and consistent performance. It typically involves daily cleaning of adhesive rollers and sensors, regular lubrication of moving parts, and periodic inspection of wear components like brushes and belts. Following the manufacturer's recommended maintenance schedule is key to minimizing unplanned downtime.

Recommended Products

Recently Viewed

Unlock the Power of Labelers: Enhance Efficiency and Precision in Every Task

Unlock the Power of Labelers: Enhance Efficiency and Precision in Every Task Enhancing Efficiency with Labelers: A Comprehensive Guide

Enhancing Efficiency with Labelers: A Comprehensive Guide The Perfect Fit: A Deep Dive into Automated Glass Bottle Labeling Machines

The Perfect Fit: A Deep Dive into Automated Glass Bottle Labeling Machines The Unseen Engine of Modern Packaging: A Comprehensive Guide to Labeling Machines

The Unseen Engine of Modern Packaging: A Comprehensive Guide to Labeling Machines How Automated Labeling Systems Revolutionize Modern Operations

How Automated Labeling Systems Revolutionize Modern Operations

Contact Us

Guangzhou Change Machinery Co., Ltd.