Welcome!

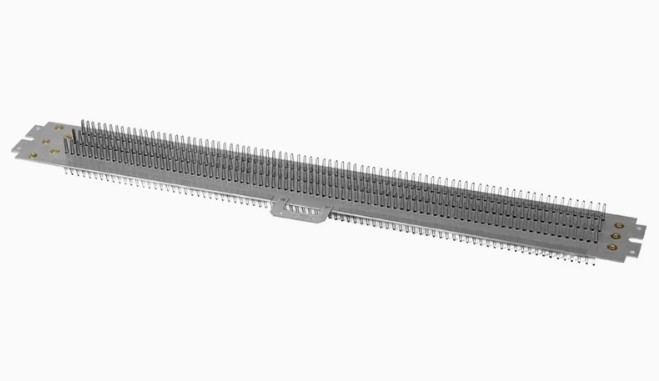

Ceramic Rod Heater: Efficient & Reliable Heating Technology

Basic Info

| Density | 2.6~2.8 g/cm3 | HS Code | 8516800000 | Install | Easy |

|---|---|---|---|---|---|

| Shape | ED, Gd, SCR, Sgr, Dumbbell, U, UL, H, W, Spiral | Transport Package | Wooden Box | Usage | Ceramic, Glass, Semiconductor |

Product Description

A Ceramic Rod Heater is an advanced electric heating element utilizing Positive Temperature Coefficient (PTC) ceramic material as its core. Encased within a robust metal sheath (often aluminum fins), the ceramic rod generates heat when an electrical current passes through it. The defining characteristic of PTC ceramic is its self-regulating property: as the temperature increases, its electrical resistance rises sharply, automatically reducing power consumption once the target temperature is reached. This inherent safety and efficiency make ceramic rod heaters ideal for diverse heating applications.

Key Advantages:

Exceptional Energy Efficiency: The self-regulating PTC effect prevents overheating and significantly reduces energy consumption compared to constant-resistance heaters, as power draw drops dramatically once stabilized.

Inherent Safety: Automatic temperature limiting eliminates the risk of dangerous overheating, even if airflow is blocked or control systems fail. No red-hot elements exist.

Long Service Life & Reliability: The robust ceramic core and solid-state construction offer excellent resistance to thermal shock, vibration, and corrosion, leading to minimal maintenance and long operational life.

Compact Design & High Power Density: Ceramic rods deliver substantial heat output from a relatively small physical footprint, allowing for flexible integration into space-constrained designs.

Fast Response & Low Noise: Heats up quickly to operating temperature. Operates silently, as no fan is required for the heater core itself (though systems may use fans for air movement).

Primary Applications:

Industrial Processes: Drying ovens, packaging machinery, laminators, plastic welding, shrink tunnels, process air heating.

HVAC & Appliances: Fan heaters, convection heaters, air curtains, dehumidifiers, clothes dryers, hair dryers, soldering irons.

Automotive: Cabin heaters (especially EVs), seat heaters, mirror defrosters, battery thermal management pre-heating.

Medical & Laboratory Equipment: Incubators, sterilizers, sample dryers.

Consumer Electronics: 3D printer heated beds, specialized warming devices.

Q: What voltage do ceramic rod heaters typically operate on?

A: Ceramic rod heaters are commonly available for standard AC voltages like 120V, 220V, 230V, or 240V AC, and increasingly for DC voltages (e.g., 12V, 24V, 48V) used in automotive and portable applications. Always check the specific heater's rated voltage before use.

Q: How do I clean a ceramic rod heater?

A: Ensure the heater is completely cool and disconnected from power. Use compressed air to gently blow away loose dust and debris from the fins and surfaces. For stubborn dirt, lightly wipe the fins with a soft, dry cloth or a cloth slightly dampened with water or a mild detergent solution. Never immerse the heater in water or use abrasive cleaners.

Q: What is the maximum temperature a ceramic rod heater can reach?

A: The maximum surface temperature depends on the specific PTC ceramic formulation and the heater's design (including fin density and airflow). Common maximum operating surface temperatures range from around 150°C (300°F) up to 450°C (840°F) or higher for specialized industrial units. Consult the manufacturer's datasheet for the exact specification.

Q: Are ceramic rod heaters fragile?

A: The ceramic PTC element itself is brittle and can be damaged by severe physical impact or bending forces. However, the heaters are designed with protective metal sheaths (fins) that provide significant mechanical protection during normal handling and operation. Treat them with reasonable care, avoiding drops or excessive force.

Q: Why doesn't my ceramic rod heater feel very hot even when it's on?

A: This is likely due to the self-regulating nature and the design. If the surrounding air or object is already near the heater's target temperature, the PTC effect drastically reduces power input, so the surface won't get excessively hot. Additionally, the large surface area of the fins efficiently transfers heat to the air, meaning the fins themselves may not feel scorching hot to the touch compared to a small, exposed coil. If no heat output is detected, check power supply and connections.

Recommended Products

Recently Viewed

The Warm Embrace of Electric Heaters: Comfort at Your Fingertips

The Warm Embrace of Electric Heaters: Comfort at Your Fingertips Stay Warm: Unlocking the Versatile World of Electric Heaters

Stay Warm: Unlocking the Versatile World of Electric Heaters Introduce The Efficiency, Durability And Safety of Ceramic Heating Rods

Introduce The Efficiency, Durability And Safety of Ceramic Heating Rods Detailed Introduction of Alumina Ceramic Heating Rods

Detailed Introduction of Alumina Ceramic Heating Rods A Comprehensive Guide to Electric Heaters: Efficient, Versatile, and Convenient Heating Solutions

A Comprehensive Guide to Electric Heaters: Efficient, Versatile, and Convenient Heating Solutions

Contact Us

JiangYin Hengyan Electric Appliance Co., Ltd.