Welcome!

Ceramic Fiber Materials: Engineered for Extreme Heat Management

Basic Info

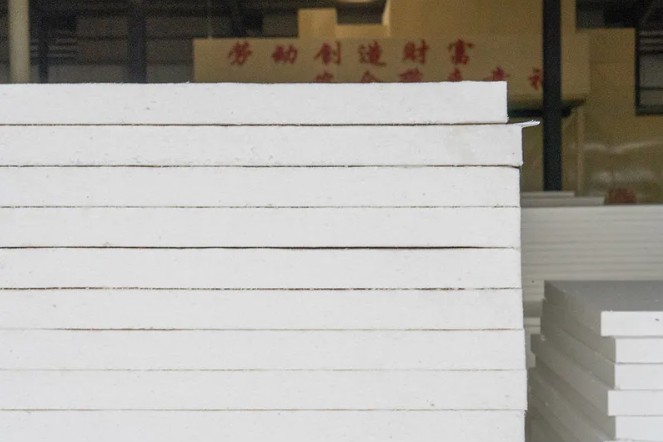

| Chemical Composition | SiO2, Al2O3.SiO2, Al2O3 | Kind | Refractory Material | Manufacturing Technique | Vacuum Forming |

|---|---|---|---|---|---|

| Model NO. | JDTX-DG-03 | Origin | China | Shape | Ceramic Fiber Plate |

| Specification | 900x600x50mm/1200x600x50mm/1200x1000x50mm | Transport Package | Carton/Pallet | ||

Product Description

Product Overview

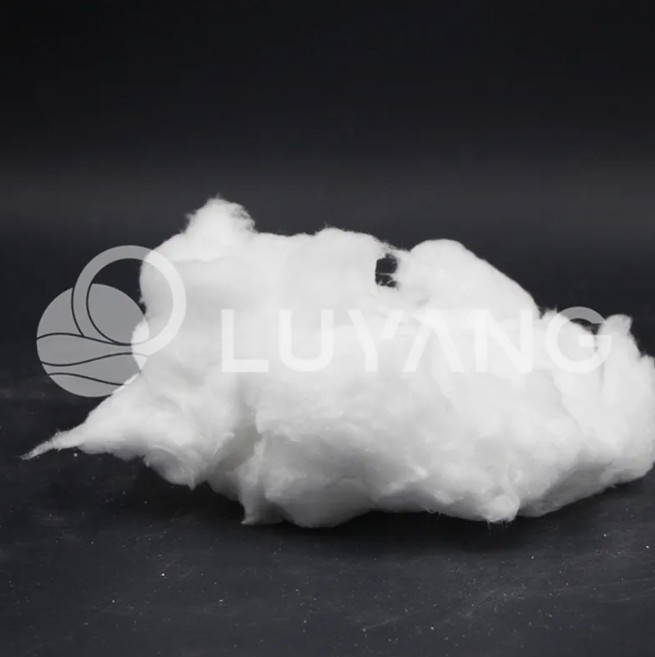

Ceramic fiber materials represent a class of high-performance and lightweight refractory insulation designed for the most demanding thermal environments. Synthesized primarily from alumina and silica, these inorganic materials are processed into fine and interlocking fibers, creating a low-density matrix with exceptional insulating properties. Available in versatile forms, including bulk fibers, rolls (blankets), rigid boards, pre-fabricated modules, papers, felts, and textiles, ceramic fiber solutions cater to a vast array of high-temperature industrial applications. Their defining capability is sustained operation under continuous exposure to extreme temperatures typically from 1260°C (2300°F) up to 1600°C (2912°F) based on composition (standard, high-purity, or zirconia-enriched grades).

This unique fibrous structure acts as a robust thermal shield, effectively impeding heat transfer via conduction and convection. The inherent flexibility of many ceramic fiber products ensures straightforward installation on complex equipment shapes and within confined spaces, providing seamless thermal protection where traditional rigid materials fail.

Key Advantages

1. Unmatched Thermal Stability: Maintain integrity and insulating performance under continuous exposure to ultra-high temperatures far beyond conventional insulation limits.

2. Superior Insulating Efficiency: Extremely low thermal conductivity minimizes heat flow, leading to significant reductions in energy consumption and enhanced process temperature uniformity.

3. Rapid Thermal Response: Exceptionally low heat storage capacity enables faster heating and cooling cycles in equipment like furnaces and kilns, boosting throughput and operational efficiency.

4. Outstanding Thermal Shock Resistance: Withstand severe and rapid temperature fluctuations without cracking or degradation, ensuring reliability in cyclic processes.

5. Inherent Chemical Resistance: Exhibit stability against attack by most acids, solvents, oils, and water vapor (excluding strong alkalis and hydrofluoric acid), enhancing longevity in corrosive atmospheres.

6. Significant Weight Reduction: Dramatically lighter than traditional brick or castable refractories, lowering structural load requirements and simplifying equipment design and installation.

7. Design Flexibility & Ease of Installation: Flexible forms (blankets, modules, ropes) can be easily cut, shaped, and fitted to complex geometries, minimizing installation time and thermal bridging.

8. Mechanical Durability (Rigid Forms): Boards and modules offer enhanced surface hardness, resistance to erosion from moderate gas flows, and easier handling.

9. Tangible Energy & Cost Savings: High insulating efficiency translates directly to lower fuel or power consumption, reducing operational expenses and carbon footprint.

10. Enhanced Personnel Safety: Significantly lower external surface temperatures of hot equipment, mitigating burn risks and improving workplace safety.

11. Comprehensive Application Versatility: Wide range of forms, densities, and temperature grades available for diverse needs from furnace linings and pipe insulation to gasketing and expansion joint sealing.

12. Acoustic Insulation Properties: The fibrous nature provides effective sound absorption, contributing to noise reduction in high-temperature plant environments.

Who We Are?

Luyang Energy-Saving Materials Co., Ltd. is a leading manufacturer dedicated to developing, producing, and supplying high-performance thermal insulation and energy-saving solutions for diverse construction and industrial applications worldwide. Leveraging advanced material science and rigorous quality control, the company offers a comprehensive portfolio of innovative products designed to significantly reduce energy consumption, lower carbon emissions, enhance building efficiency, and provide sustainable economic benefits to its global clientele.

Conclusion

Ceramic fiber materials are the cornerstone of efficient and safe thermal management in extreme heat applications. Their unique combination of ultra-high temperature capability, exceptional insulating properties, lightweight design, and versatility delivers measurable benefits in energy conservation, process optimization, equipment protection, and operational safety across industries such as metal processing, petrochemicals, power generation, ceramics, and aerospace. This advanced insulation solution offers a critical advantage for modern high-temperature operations demanding peak performance and reliability.

Recommended Products

Recently Viewed

Ceramic Fiber Materials: Superior High-Temperature Insulation Solutions

Ceramic Fiber Materials: Superior High-Temperature Insulation Solutions The manufacturer wholesales high-temperature insulation ceramic fiber blankets

The manufacturer wholesales high-temperature insulation ceramic fiber blankets Ceramic Fiber Materials: Powering Efficiency in Extreme Heat Environments

Ceramic Fiber Materials: Powering Efficiency in Extreme Heat Environments High-quality fireproof calcium silicate boards are used for fire protection pipelines

High-quality fireproof calcium silicate boards are used for fire protection pipelines Ceramic Fiber Materials: Engineered for Extreme Heat Management

Ceramic Fiber Materials: Engineered for Extreme Heat Management

Contact Us

Luyang Energy-Saving Materials Co., Ltd.