Welcome!

Revolutionizing Packaging Efficiency: An In-Depth Look at Plastic Packaging Machines

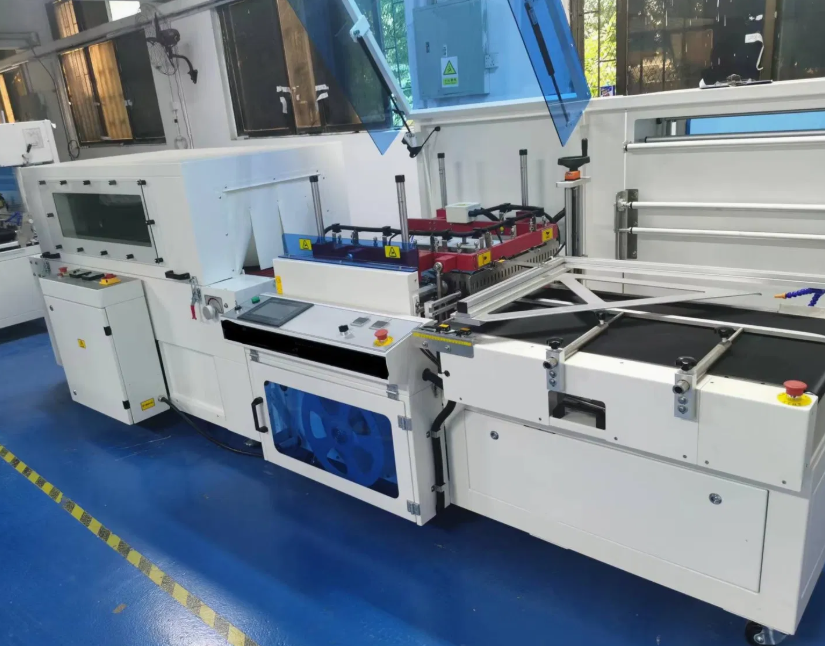

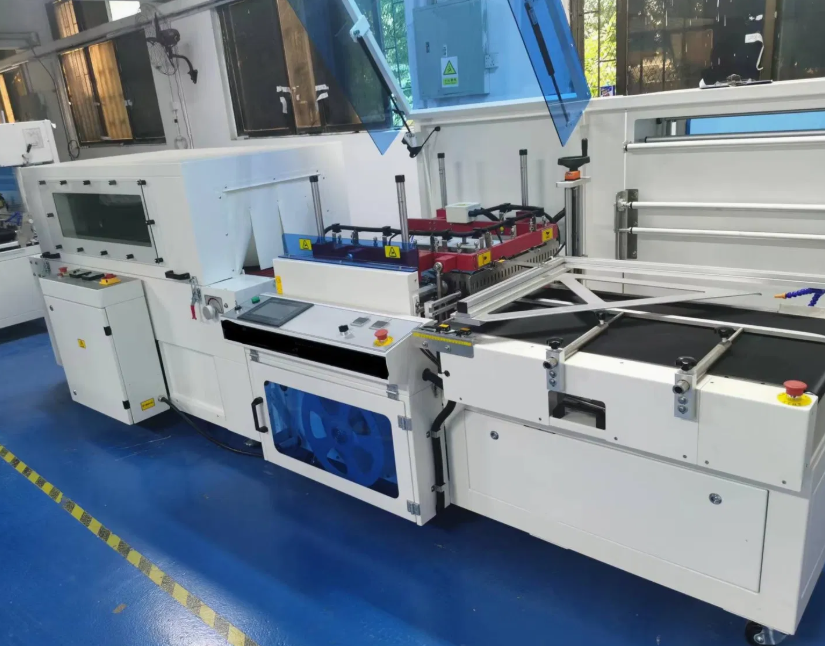

Basic Info

| Adjust Speed | Electronic Speed Control | After-Sales Service Provided | Engineers Available to Service Machinery Overseas | Automatic Grade | Automatic |

|---|---|---|---|---|---|

| Driven Type | Electric | End Bar Seal Size | 450 X 335 | Heating Mode | Stainless Steel Heating |

| Manner of Packing | One End Open | Origin | China | Packaging | Film |

| Packaging Material | Wooden | Packing Size | 50-400 X 50-280 X 2-80 | Packing Speed | 40-60(Bag/Min) |

| Production Capacity | 10000 | Specification | 1485 x 1320x 1230 | Transport Package | Wooden Case |

| Type | POF Shrink Film Machine | Usage | Outer | ||

Product Description

In today's fast-paced industrial environment, efficiency, cost-effectiveness, and versatility are paramount for businesses looking to streamline their operations. Plastic packaging machines, a vital component of modern manufacturing, offer a cutting-edge solution to packaging challenges across numerous industries. From food and beverage to electronics and pharmaceuticals, these machines are transforming how products are packaged and distributed globally.

Core Features and Advantages of Plastic Packaging Machines

Plastic packaging machines are engineered to automate the packaging process, providing both high-speed performance and precision. These machines are designed to handle various plastic materials, including polyethylene, polypropylene, and polyvinyl chloride among others. They ensure a secure and efficient seal, preventing product contamination and enhancing shelf life.

One of the most significant advantages of plastic packaging machines is their ability to cater to a wide range of product sizes and types. Whether it's small and delicate items or larger bulk products, these machines can be customized to fit the specific needs of the product being packaged. This versatility makes them indispensable across industries from packaging consumer goods to industrial components.

Plastic packaging machines are also known for their energy efficiency. Many models incorporate advanced technology that minimizes energy consumption while maximizing output. This is especially crucial in industries where operational costs are a major consideration. Moreover, these machines offer high-speed production capabilities, which means they can handle large volumes of packaging in a short amount of time, boosting productivity and meeting demanding deadlines.

Key Applications of Plastic Packaging Machines

The scope of plastic packaging machines extends beyond just one or two industries. These machines are used in diverse fields, including:

1. Food and Beverage Industry: Plastic packaging machines are essential in preserving the freshness of food and beverages. They help in sealing products in plastic pouches, bottles, or containers, preventing spoilage, contamination, and maintaining product integrity during transportation and storage.

2. Pharmaceuticals and Healthcare: In the pharmaceutical industry, precision and hygiene are of utmost importance. These machines ensure that medicines and healthcare products are packaged in a sterile and secure manner. Additionally, they often come with customizable settings to handle a wide range of packaging formats from blister packs to bottles.

3. Consumer Goods: From cosmetics to household products, plastic packaging machines are crucial in ensuring that consumer goods are packaged securely and efficiently. Their ability to adapt to different product types makes them perfect for brands looking for flexibility and high-volume production.

4. Electronics: Many electronic products, particularly small gadgets and components, require specialized plastic packaging to protect against physical damage and environmental factors. Plastic packaging machines excel in this application by providing protective packaging that meets industry standards.

Long-Term Value and Investment

The long-term benefits of integrating plastic packaging machines into manufacturing operations are clear. By improving packaging efficiency, reducing labor costs, and enhancing product protection, businesses can boost their overall profitability. Additionally, as consumer demand for sustainable and eco-friendly packaging continues to grow, manufacturers are increasingly opting for plastic packaging machines that offer biodegradable or recyclable packaging solutions. This reflects the broader industry trend toward sustainability, allowing businesses to meet both consumer expectations and regulatory requirements.In conclusion, plastic packaging machines are indispensable tools for businesses looking to optimize their packaging processes. With their advanced features, versatility, and long-term cost savings, they offer a reliable and efficient solution for industries worldwide. Whether you're in food processing, pharmaceuticals, or consumer goods, these machines are a crucial investment in the modern age of manufacturing. Their ability to enhance productivity, protect products, and provide scalable solutions makes them a cornerstone of successful packaging operations across the globe.

Recommended Products

Recently Viewed

Revolutionizing Packaging Efficiency: The Power of Plastic Packaging Machines

Revolutionizing Packaging Efficiency: The Power of Plastic Packaging Machines Efficient and Versatile Plastic Packaging Machines: Revolutionizing the Packaging Industry

Efficient and Versatile Plastic Packaging Machines: Revolutionizing the Packaging Industry Innovative Food Packaging Machines: Ensuring Freshness and Efficiency for Your Business

Innovative Food Packaging Machines: Ensuring Freshness and Efficiency for Your Business Unlocking the Future of Food Packaging: Revolutionizing Efficiency with Food Packaging Machines

Unlocking the Future of Food Packaging: Revolutionizing Efficiency with Food Packaging Machines Revolutionizing the Food Industry with Efficient Food Packaging Machines

Revolutionizing the Food Industry with Efficient Food Packaging Machines

Contact Us

Guangzhou Duoshun Machinery Co., Ltd.