Welcome!

Guangdong Shunde Jiaheda Cleaning Equipment Co., L

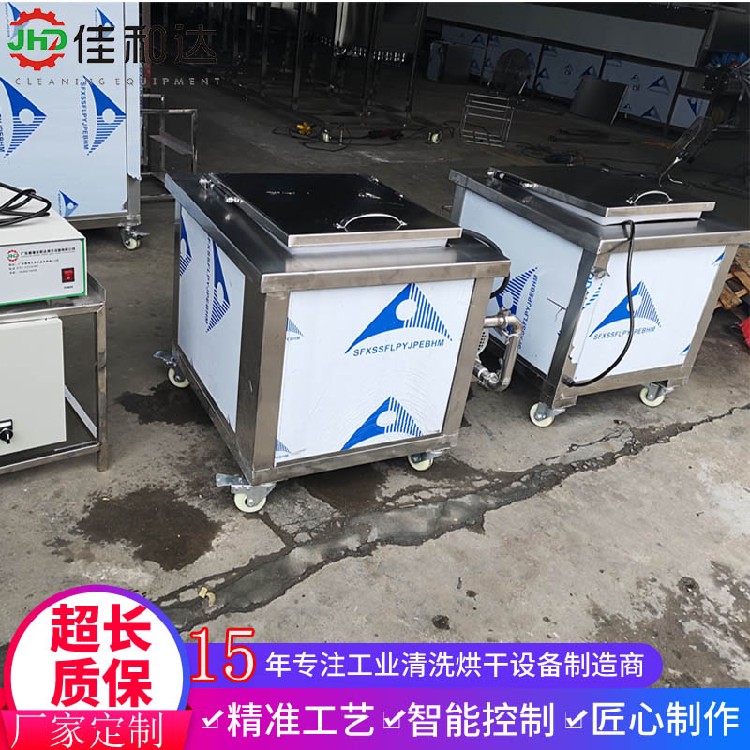

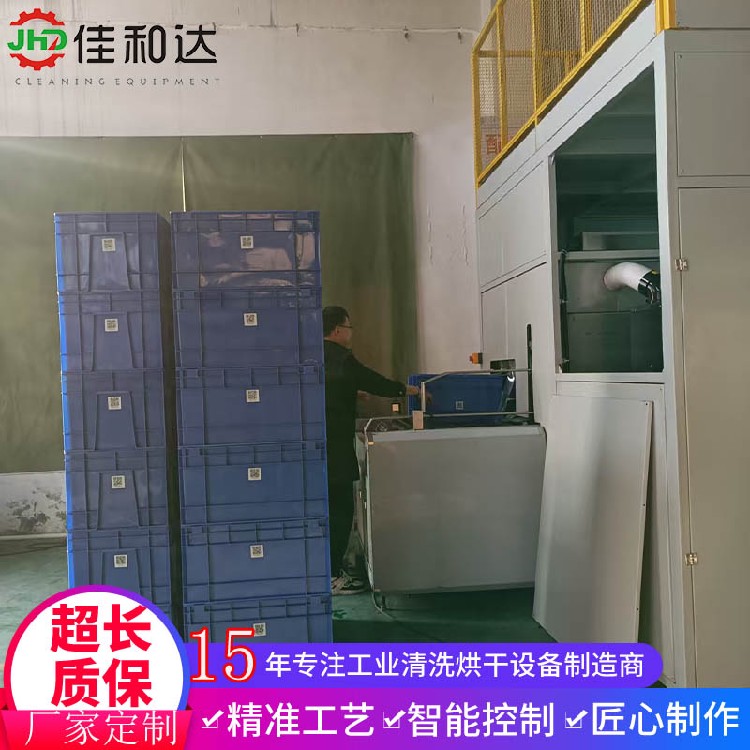

Main products: Ultrasonic cleaning machine , spray cleaning machine, high-temperature drying line, oil removal cleaning line, hanging cleaning and drying line, gantry automatic cleaning line, wax removal cleaning and drying line, box washing machine, high-pressure washing machine, flat brush cleaning machine, tunnel drying oven, natural gas cleaning and drying equipment

Sink cleaning and drying line

Basic Info

| Size | Customization | ||||

|---|---|---|---|---|---|

Product Description

I. Product Overview

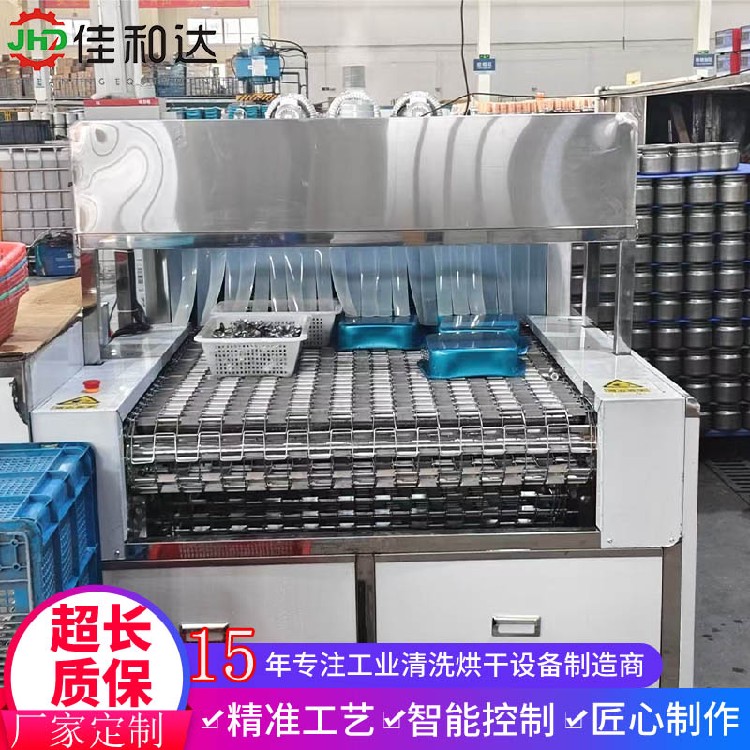

The through ultrasonic cleaning machine is a kind of fully automatic and efficient industrial cleaning equipment. It adopts the continuous conveying method of conveyor belt to realize the automation of the whole process of workpieces from feeding, cleaning, rinsing to drying. The equipment combines ultrasonic cavitation effect and spray flushing technology. It is specially designed for large-scale and high-clean cleaning needs, and is widely used in automobile, electronics, hardware, medical and other industries.

II. Equipment structure and working principle

1. Main body structure

Cleaning tank body: multi-slot series design (common 3-8 slots), made of 304/316L stainless steel, resistant to acid and alkali corrosion.

Transmission system: variable frequency speed conveyor belt (net belt/chain plate type), adjustable speed (0.5-5m/min).

Ultrasonic system: 40kHz/80kHz high-frequency vibration box, adjustable power (control per slot).

Spraying system: high-pressure rotary spraying arm, 360° flushing.

Drying system: hot air circulation drying (cold air cooling workstation can be selected).

2. Workflow

Loading → pre-washing → ultrasonic coarse washing → ultrasonic fine washing → spray rinsing → pure water rinsing → hot air drying → unloading

(The process can increase or decrease the tank according to the process requirements)

III. Core technologies and advantages

1. Cleaning ability

The ultrasonic cavitation effect can remove oil stains, polishing paste and particle impurities on the surface of the workpiece, which is especially suitable for complex structural parts (such as blind holes and threads).

The pressure of the sprinkler system is adjustable (0.2-0.8MPa), which assists in the removal of stubborn stains.

2. Intelligent control

PLC+touch screen control, can store 100+ groups of process parameters, and switch different workpiece cleaning modes with one click.

Real-time monitoring of temperature, speed and liquid level, abnormal automatic alarm (lack of liquid/overheating).

3. Energy-saving and environmental protection design

Circulation filtration system (optional activated carbon/membrane filtration), cleaning agent recovery rate ≥80%.

Exhaust gas treatment module (optional) meets VOC emission standards.

4. Durability and safety

The equipment protection level is IP65, and the motor/electric control box is moisture-proof and dust-proof.

Overload protection, leakage protection, emergency stop button.

IV. Technical parameters (standard model reference

Project Parameter Description

Cleaning tank size 600mm×400mm×300mm (customizable)

Ultrasonic frequency 40kHz/80kHz (optional dual frequency)

Heating power 6kW/trough (room temperature~90℃±2℃)

Conveyor belt load 50kg/m

Power supply 380V/50Hz (optional 220V)

V. Typical application industries

1. Auto parts

Cleaning objects: engine parts, bearings, gears

Remove pollutants: cutting oil, anti-rust oil, metal shavings

2. Electronic manufacturing

Cleaning object: PCB board, connector, heat sink

Remove pollutants: flux, tin slag, dust

3. Hardware plating

Cleaning objects: screws, locks, bathroom accessories

Remove pollutants: polishing wax, mold release agent

VI. Optional functions

Customized groove lengthening (suitable for extra-long workpieces)

Vacuum drying system (alternative hot air drying)

Pickling/Passimation function (metal surface treatment)

VII. Service support

Free process debugging and operation training

1-year warranty, lifetime technical support

Non-standard customization

Remarks: The above parameters are general models, and the specific configuration needs to be adjusted according to the material, size and cleaning requirements of the workpiece. Free sample service is available to verify the cleaning effect.

Recommended Products

Recently Viewed

Contact Us

Guangdong Shunde Jiaheda Cleaning Equipment Co., L