Welcome!

Guangdong Shunde Jiaheda Cleaning Equipment Co., L

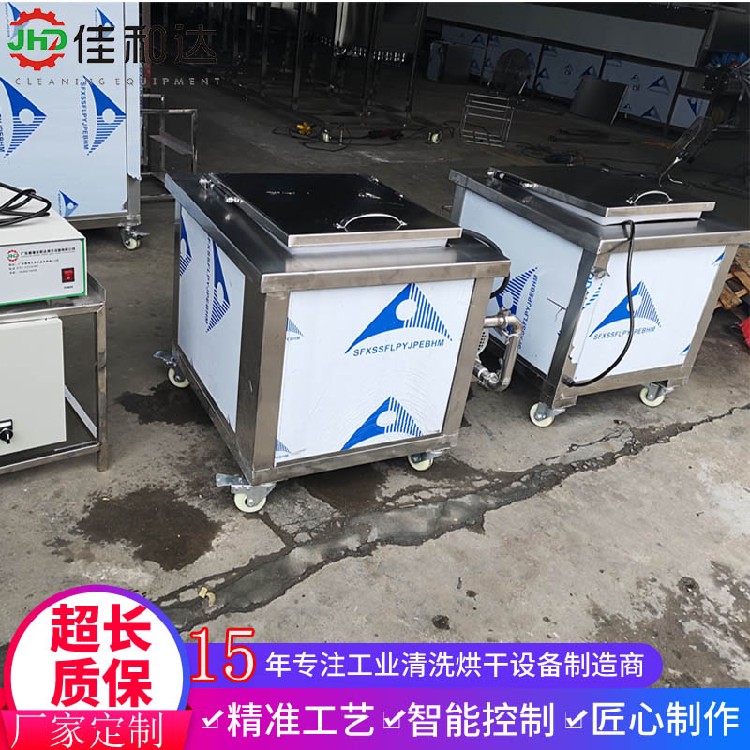

Main products: Ultrasonic cleaning machine , spray cleaning machine, high-temperature drying line, oil removal cleaning line, hanging cleaning and drying line, gantry automatic cleaning line, wax removal cleaning and drying line, box washing machine, high-pressure washing machine, flat brush cleaning machine, tunnel drying oven, natural gas cleaning and drying equipment

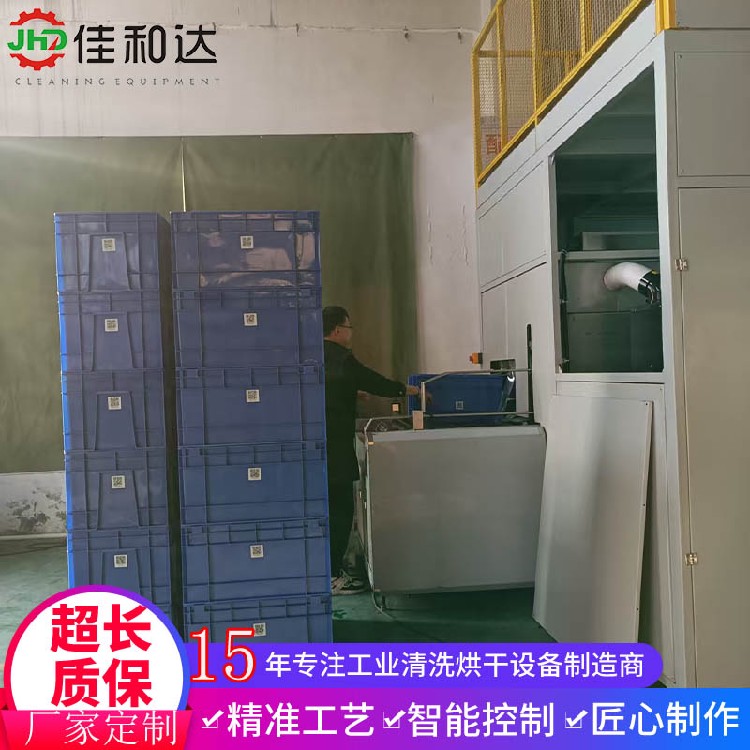

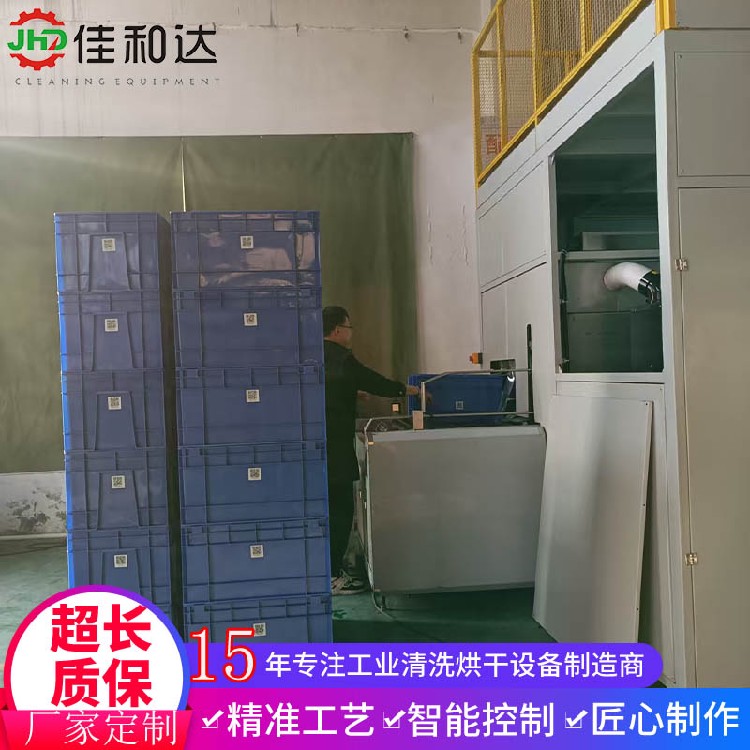

High-efficiency continuous sprinkler cleaning line of turnover box

Basic Info

| Size | Customization | ||||

|---|---|---|---|---|---|

Product Description

I. Equipment Profile

This device is an automated device that utilizes high pressure spray technology for continuous cleaning, sterilization and drying of plastic / metal rotary boxes. The whole machine is made of 304 stainless steel, with a compact structure and strong corrosion resistance. The rotary boxes are carried by conveyor belts and pass through various functional compartments at a constant speed, enabling a one-stop treatment of "dirty boxes in, clean boxes out," which is a perfect alternative to inefficient and costly manual cleaning.

II. Detailed workflow

1. Loading area: The unwashed turnaround box is placed on the conveyor belt by hand or through an automated conveyor line.

2. High pressure pre-flushing segment: Using circulating hot water, a strong initial rinse of the rotating box is performed to remove most of the attachments.

3. Main cleaning segment: spray specialty cleaning agents, stereoscopic cleaning through multi-directional nozzles, up and down, to completely break down oil and stubborn stains.

4. Water washing segment: Use clean water for multiple stages of washing to ensure there are no detergent residues.

5. Disinfection / maintenance phase (optional): spraying a disinfectant (such as chlorine dioxide) or maintenance agent to kill germs and extend the life of the turnaround box.

6. Strong drying segment: Use an efficient wind knife to blow away most of the water droplets on the surface of the box, shortening the natural drying time.

7. Bottom Line: Clean, slightly wet turnaround boxes are sent out and can be put into use directly or put to a brief drying.

III. Core strengths

· Tailored: According to your turnover box size, the extent of pollution and capacity requirements, customized conveyor belt speed, cabin length and nozzle layout.

· Water circulation system: Built-in multi-level filtering (such as hair filters, precision filters), most of the cleaning water can be recycled, saving up to 70%.

· Intelligent control: PLC touch screen control system, can accurately set the water temperature, pressure, time and other parameters, simple operation, stable operation.

· Easy maintenance: The main nozzle has a fast connection design, and the filters can be easily removed and cleaned, greatly reducing the daily maintenance workload.

IV. Technical parameters (examples, to be filled in according to the actual model)

· Applicable box size: L 400-600mm × W 300-500mm × H 200-300mm

· Cleaning capacity: 200-800 boxes per hour (djustable)

· Power supply: approximately 25-40 kW

· Water consumption: approximately 1-3 tons per hour (related to configuration)

· Material of the whole machine: 304 stainless steel

· Conveyor belt speed: 0.5-5 m / min (stepless adjustable)

5. Which industries are they suitable for?

· Food and beverage industry: Clean turnaround boxes containing meat, vegetables, pastries, bottles and cans to ensure food hygiene and safety.

· Pharmaceutical and biological industry: meet the GMP cleanliness requirements, used for cleaning raw materials barrels, tool containers.

· Chemical & Manufacturing: Removing oil, metal debris, and residues of chemical raw materials.

· Logistics and retail: Keep shared turnaround boxes and logistics baskets tidy and improve the brand image.

Recommended Products

Recently Viewed

Contact Us

Guangdong Shunde Jiaheda Cleaning Equipment Co., L