Welcome!

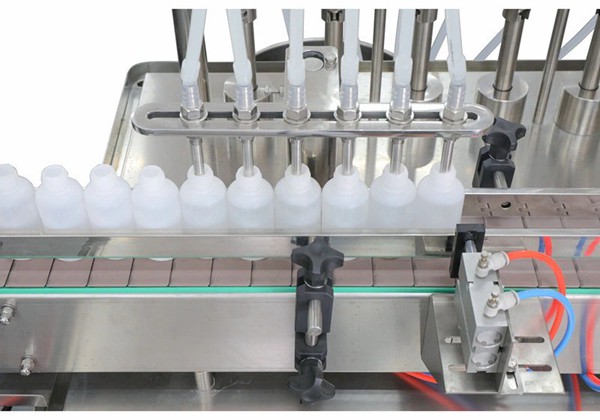

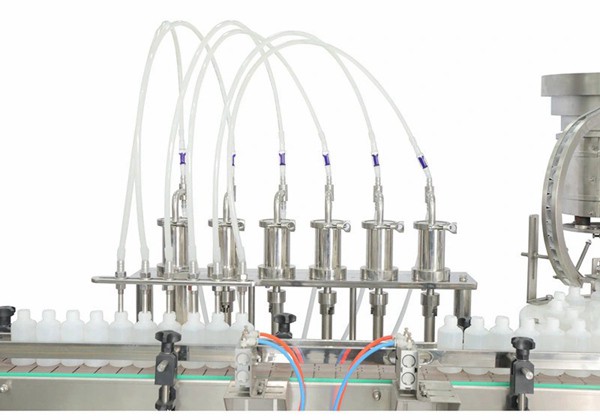

The fully automatic water bottle filling machine is for sale

Basic Info

| Application | Beverage | Automatic Grade | Automatic | Certification | CE |

|---|---|---|---|---|---|

| Color Choose | No | Control | PLC | Customized | Customized |

| Dianya | 380V | Filling Head | 8-50 | HS Code | 8422301090 |

| PLC | Mitsubishi | Power Source | Electric | Processing Material | Liquid |

| Processing Type | Water | Quality | High | Specification | ISO9001 |

| Status | New | Transport Package | Wooden Packages | ||

Product Description

In an era where convenience, sustainability, and hygiene are paramount, the automatic water bottle filling machine has emerged as an innovative solution for public spaces, offices, gyms, and homes. This technology streamlines the process of refilling reusable bottles, reducing plastic waste while promoting efficient water consumption. Let’s explore how these machines work, their benefits, and their growing role in modern society.

How It Works

Automatic water bottle filling machines combine sensor-based automation with user-friendly design. Equipped with infrared or motion sensors, the machine detects a bottle’s presence and activates the filling mechanism. Users simply place their bottle under the dispenser, and the machine adjusts the water flow to match the container’s size, preventing spills. Advanced models may include filtration systems to ensure clean, chilled, or even carbonated water. Once filled, the machine resets automatically, which is ready for the next user.

Key Features and Applications

Sustainability Champion: By encouraging reusable bottles, these machines drastically cut single-use plastic consumption. Many models display real-time metrics (e.g., "plastic bottles saved"), reinforcing eco-conscious behavior.

Hygiene and Safety: Touchless operation minimizes germ transmission, making them ideal for high-traffic areas like airports, schools, and hospitals.

Versatility: They accommodate various bottle sizes and shapes from compact tumblers to large jugs.

Smart Integration: Some units connect to IoT networks for remote monitoring, maintenance alerts, or data collection on usage patterns.

Common applications include:

Commercial Spaces: Gyms, offices, and shopping malls.

Public Infrastructure: Parks, transit hubs, and universities.

Industrial Use: Factories and warehouses where hydration stations boost worker well-being.

Advantages Over Traditional Solutions

Compared to conventional water coolers or fountains, automatic filling machines offer:

Speed: Fill a 500ml bottle in seconds.

Water Conservation: Precision sensors reduce spillage by up to 90%.

User Experience: No manual lever-pulling; ideal for accessibility needs.

Cost Efficiency: Lower long-term expenses by minimizing plastic procurement and waste management.

The Future of Hydration

As smart cities and green initiatives gain momentum, these machines are evolving. Future iterations may incorporate AI to predict peak usage times, self-cleaning mechanisms, or even solar-powered operation. Partnerships with sustainability organizations further amplify their environmental impact.

Conclusion

The automatic water bottle filling machine is more than a convenience—it’s a symbol of progress toward a sustainable and health-conscious future. By merging technology with eco-friendly principles, it addresses global challenges like plastic pollution and resource conservation. Whether in a bustling urban center or a quiet office corner, this innovation ensures that staying hydrated is effortless, safe, and kind to the planet.

About Us

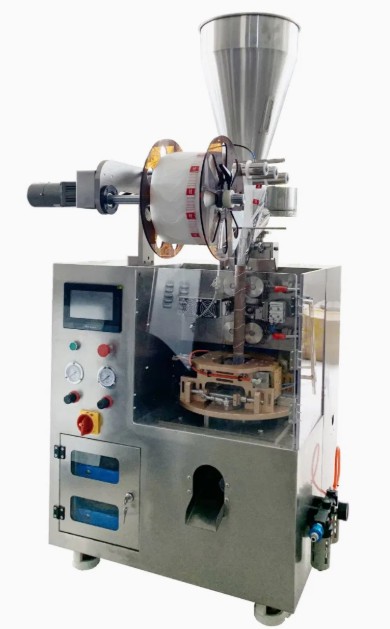

Shanghai Leadworld Machinery Technology Co., Ltd. is specialized in developing researching and manufacturing various whole sets of packing production systems, and we own marketing, import and export ability.

Our company is devoted to digesting and absorbing internationally advanced science of processing and automatic equipment. We have cooperated with customers from Canada, Italy, Germany, and Switzerland for a long time, and have developed various whole sets of advanced filling packing and conveying equipment reaching professional advanced level.

Our automatic production system is widely used in food, beverage, dairy product, canned product, cosmetic, lube, medicine, chemistry, and other fields. Leadworld can supply the best solution of whole sets of automatic production, filling, packing, and logistics system. Our goal is leading the world!

Recommended Products

Recently Viewed

Filling Machines: Elevate Your Packaging Process with Smart Automation

Filling Machines: Elevate Your Packaging Process with Smart Automation Filling Machines: Precision, Efficiency, and Versatility

Filling Machines: Precision, Efficiency, and Versatility Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions

Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility

Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility Efficient Liquid Filling Machines: Streamlining Your Production Process

Efficient Liquid Filling Machines: Streamlining Your Production Process

Contact Us

Shanghai Leadworld Machinery Technology Co., Ltd.