Welcome!

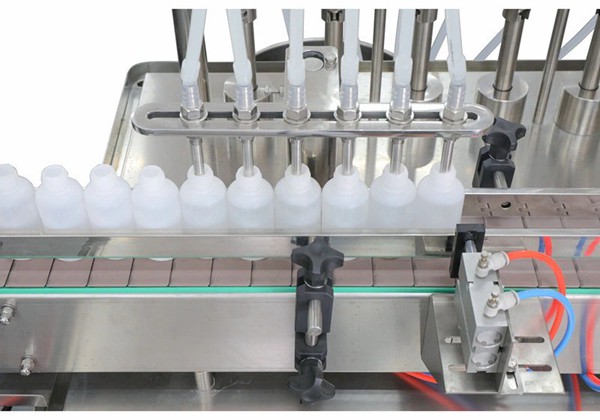

Cheap bottled water liquid filling machines are for sale

Basic Info

| HS Code | 8422301090 | Model NO. | LW | Origin | Shanghai |

|---|---|---|---|---|---|

| Production Capacity | 20 Piece Per Month | Specification | L2000*W1900*H1450mm | Trademark | leadworld |

| Transport Package | Standard Export Case | Type | Piston Filling Machine | ||

Product Description

In industries ranging from food and beverages to pharmaceuticals and cosmetics, liquid filling machines play a pivotal role in streamlining production, ensuring accuracy and maintaining product quality. These machines are engineered to handle diverse liquids from water and juices to viscous creams and chemicals with speed and precision. This article explores the types, applications, and technological advancements of liquid filling machines, highlighting their significance in today’s automated manufacturing landscape.

A liquid filling machine is an automated or semi-automated system designed to dispense precise volumes of liquid into containers such as bottles, jars, pouches, or cans. These machines are tailored to meet specific industry requirements, accommodating variations in liquid viscosity, container size, and production speed.

Key Applications Across Industries

Food & Beverage: Bottling juices, sauces, dairy products, and alcoholic beverages.

Pharmaceuticals: Precise filling of syrups, vaccines, and injectables under sterile conditions.

Cosmetics: Dispensing creams, lotions, shampoos, and perfumes.

Chemicals: Handling solvents, detergents, and lubricants.

Household Products: Filling liquid soaps, cleaners, and oils.

Advantages of Modern Liquid Filling Machines

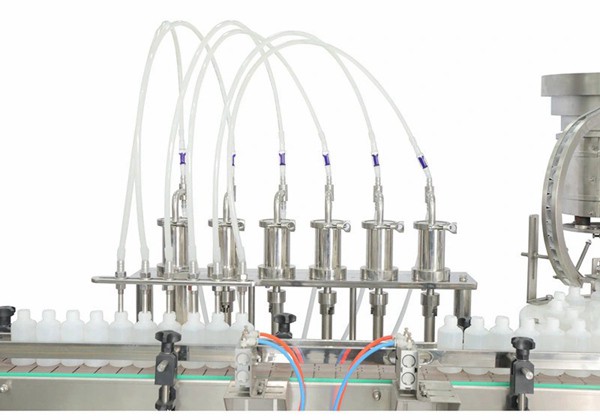

High Precision: Ensure consistent fill levels, reducing product waste and enhancing quality control.

Speed and Efficiency: Capable of filling hundreds to thousands of containers per hour, boosting production rates.

Flexibility: Adjustable settings accommodate diverse container sizes, shapes, and liquid types.

Hygiene and Safety: Stainless steel construction and CIP (Clean-in-Place) systems meet strict sanitary standards.

Cost Savings: Automation reduces labor costs and minimizes human error.

Sustainability: Optimized liquid usage and reduced spillage contribute to eco-friendly operations.

Choosing the Right Liquid Filling Machine

Selecting a machine depends on factors such as:

Liquid properties (viscosity, foaming tendency, temperature).

Container type (glass, plastic, pouches).

Production volume (small-batch vs. high-speed).

Regulatory requirements (e.g., FDA, GMP for pharmaceuticals).

About Us

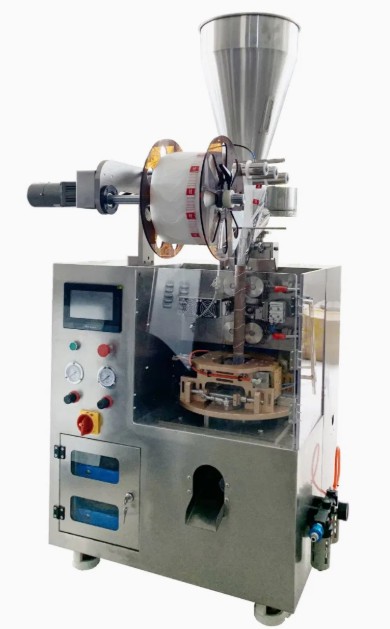

Shanghai Leadworld Machinery Technology Co., Ltd. is specialized in developing researching and manufacturing various whole sets of packing production systems, and we own marketing, import and export ability.

Our company is devoted to digesting and absorbing internationally advanced science of processing and automatic equipment. We have cooperated with customers from Canada, Italy, Germany, and Switzerland for a long time, and have developed various whole sets of advanced filling packing and conveying equipment reaching professional advanced level.

Our automatic production system is widely used in food, beverage, dairy product, canned product, cosmetic, lube, medicine, chemistry, and other fields. Leadworld can supply the best solution of whole sets of automatic production, filling, packing, and logistics system. Our goal is leading the world!

Recommended Products

Recently Viewed

Filling Machines: Elevate Your Packaging Process with Smart Automation

Filling Machines: Elevate Your Packaging Process with Smart Automation Filling Machines: Precision, Efficiency, and Versatility

Filling Machines: Precision, Efficiency, and Versatility Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions

Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility

Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility Efficient Liquid Filling Machines: Streamlining Your Production Process

Efficient Liquid Filling Machines: Streamlining Your Production Process

Contact Us

Shanghai Leadworld Machinery Technology Co., Ltd.