Welcome!

Innovative Filling Machines: Engineered for Precision, Scalability, and Compliance

Basic Info

| Dosing Device | Surface Type | Feed Cylinder Structure | Single-Room Feeding | Filling Principle | Atmospheric Pressure |

|---|---|---|---|---|---|

| Filling Valve Head | Multi-Head | Material Type | Liquid | Model NO. | MFS24-24-8 |

| Origin | China | Packaging | Bottle | Packaging Container Lifting Structure | Chute Lifting |

| Packaging Material | Plastic | Production Capacity | 100 Pieces/Year | Specification | CE |

| Structure | Rotary | Transport Package | Wooden Case | ||

Product Description

Product Introduction

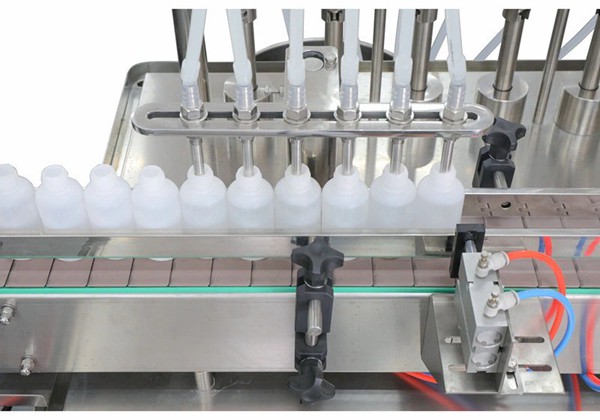

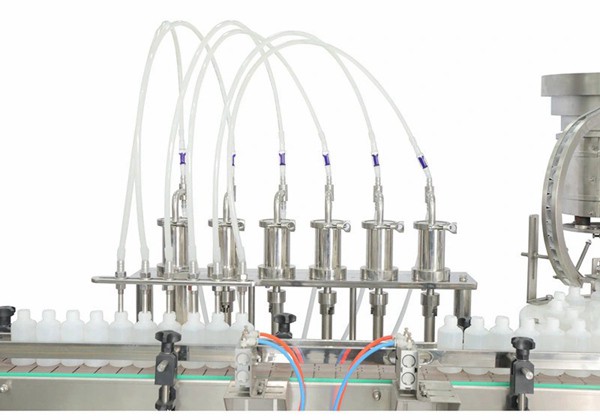

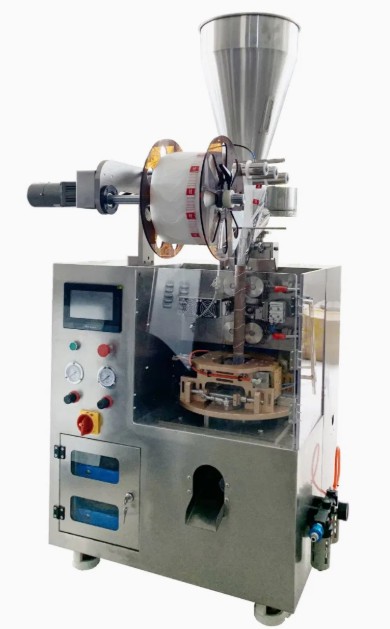

Filling machines are advanced industrial equipment designed to automate the process of accurately dispensing liquids, semi-liquids, powders, or granular products into containers such as bottles, cans, pouches, or tubes. These machines are essential for industries requiring high-speed, consistent, and hygienic packaging solutions, including food and beverage, pharmaceuticals, cosmetics, chemicals, and household products.

Modern filling machines are engineered to handle diverse product viscosities from water-thin liquids to thick pastes and volatile substances while maintaining precision and efficiency. They are available in multiple configurations, including rotary, inline, piston, gravity, and volumetric systems, tailored to meet specific production needs. Depending on automation levels, they can operate as standalone units or integrate seamlessly into fully automated production lines.

Key Advantages

1. Precision and Consistency

Filling machines ensure exact volume or weight measurements for every container, eliminating human error and minimizing product waste. This accuracy is critical for compliance with industry regulations particularly in pharmaceuticals and food production where strict dosing standards apply.

2. High-Speed Performance

Engineered for productivity, these machines significantly outperform manual filling processes, capable of filling hundreds to thousands of containers per hour. This boosts throughput, reduces labor costs, and accelerates time-to-market for high-demand products.

3. Versatility

Adaptable to a wide range of container sizes, shapes, and materials (glass, plastic, metal), filling machines can be reconfigured quickly for different production runs. Interchangeable nozzles and programmable settings allow seamless transitions between products from thin solvents to viscous creams.

4. Hygiene and Safety

Constructed with food-grade stainless steel and sanitary design principles, filling machines meet stringent hygiene standards for sensitive industries. Closed-system options prevent contamination, while automated operation reduces direct human contact with products.

5. Cost Efficiency

By optimizing material usage and reducing spillage, filling machines lower operational costs over time. Their durability and low maintenance requirements further enhance ROI, making them a sustainable investment for scaling production.

6. User-Friendly Operation

Intuitive touchscreen interfaces and programmable logic controllers (PLCs) simplify setup and monitoring. Operators can easily adjust parameters like fill volume, speed, and container positioning, ensuring minimal downtime during changeovers.

7. Sustainability

Many modern filling machines incorporate energy-efficient motors and eco-friendly features such as reduced material waste and cleaner production processes, aligning with global sustainability goals.

8. Compliance and Certification

Designed to meet international standards (e.g., FDA, CE, GMP), these machines provide traceability and documentation support, ensuring adherence to quality and safety protocols in regulated industries.

About Us

Shanghai Leadworld Machinery Technology Co., Ltd. is a dynamic and innovative company specializing in the design, development, and production of high-performance industrial machinery and automation solutions, committed to delivering cutting-edge technologies and reliable equipment for global clients across manufacturing, packaging, and material handling industries. With a focus on precision engineering, energy efficiency, and smart manufacturing integration, we combine state-of-the-art R&D capabilities with rigorous quality control systems to provide tailor-made machinery solutions that optimize productivity while maintaining compliance with international standards and certifications to ensure superior performance and long-term operational value for businesses worldwide.

Recommended Products

Recently Viewed

Filling Machines: Elevate Your Packaging Process with Smart Automation

Filling Machines: Elevate Your Packaging Process with Smart Automation Filling Machines: Precision, Efficiency, and Versatility

Filling Machines: Precision, Efficiency, and Versatility Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions

Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility

Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility Efficient Liquid Filling Machines: Streamlining Your Production Process

Efficient Liquid Filling Machines: Streamlining Your Production Process

Contact Us

Shanghai Leadworld Machinery Technology Co., Ltd.