Welcome!

Next-Level Paper Processing Machinery: Precision, Sustainability, and Smart Manufacturing

Basic Info

| Automation | Automatic | Certification | CE | Condition | New |

|---|---|---|---|---|---|

| Customized | Customized | Designed Speed | 400 M / Min | Finished Paper Width | 3800mm |

| Gauge | 4900mm | Origin | China | Output | 200t / 24h |

| Production Capacity | 24000t/Year | Raw Material | Waste Carton Paper, Newspaper, Box Paper | Specification | 3800mm |

| Transport Package | 1. Fixed All The Movable Parts with Plastic Films. | Working Speed | 250-380 M / Min | ||

Product Description

Comprehensive Product Overview

Modern paper processing machinery represents the pinnacle of industrial engineering, tailored to meet the rigorous demands of today’s paper and packaging industries. These systems are engineered to handle every stage of production from raw material preparation to final product finishing with unparalleled accuracy and efficiency. Key machinery types include:

1. Smart Pulping Stations: Advanced systems that blend virgin and recycled fibers while optimizing chemical usage for minimal environmental impact.

2. Dynamic Forming Sections: Hybrid forming units combining Fourdrinier and cylinder technologies for versatile sheet formation across grammages.

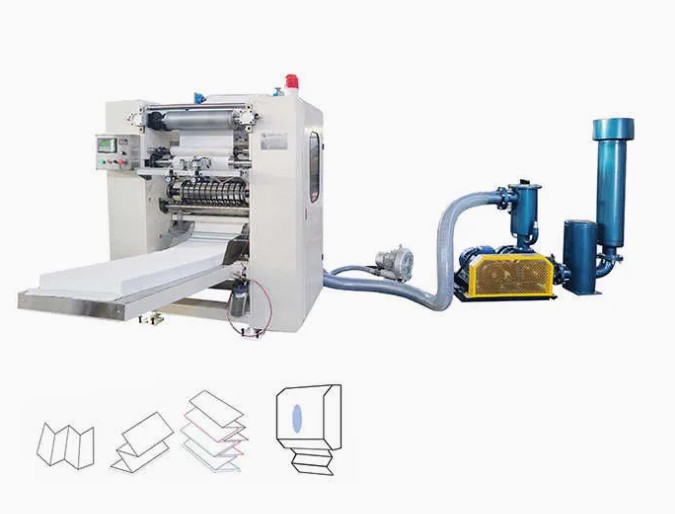

3. Precision Converting Lines: Fully automated systems for cutting, creasing, embossing, and perforating paper into ready-to-ship products.

4. Nanotechnology Coating Modules: Apply barrier coatings for moisture resistance, greaseproofing, or antimicrobial properties.

5. Zero-Waste Recycling Units: Compact systems that process in-house scrap into reusable pulp, achieving near-zero material loss.

Competitive Advantages

1. Unrivaled Precision & Consistency

- Laser-guided alignment and AI-powered quality control cameras detect micron-level deviations, ensuring that every product meets exact specifications.

- Adaptive tension control systems maintain uniformity during high-speed operations (up to 2,500 m/min).

2. Eco-Driven Innovation

- Energy Recovery Systems: Capture and reuse thermal energy from drying processes, slashing energy costs by 35%.

- Waterless Forming Technologies: Patented systems for tissue and specialty papers that eliminate water usage in sheet formation.

- Biodegradable Material Compatibility: Engineered to process plant-based fibers (e.g., bamboo, hemp) and bio-polymers for compostable packaging.

3. Scalable Automation

- Plug-and-play automation packages allow seamless integration with Industry 4.0 ecosystems, including ERP and MES platforms.

- Collaborative robots (cobots) handle repetitive tasks like roll loading, reducing labor costs by up to 50%.

4. Global Compliance & Adaptability

- Built to meet regional regulations (FDA for food-grade packaging, REACH for EU markets) and accommodate voltage or frequency variations.

- Multi-language interfaces and virtual training simulators simplify global deployment.

5. Reduced Total Cost of Ownership

- Self-lubricating components and predictive maintenance algorithms extend service intervals by 300%.

- Leasing and pay-per-use financing models available for SMEs.

6. Enhanced User Experience

- Holographic Operation Guides: AR interfaces overlay real-time instructions onto machinery, reducing training time by 70%.

- Noise & Dust Suppression: Sound-dampened enclosures and HEPA filtration create safer and cleaner workspaces.

Applications Across Industries

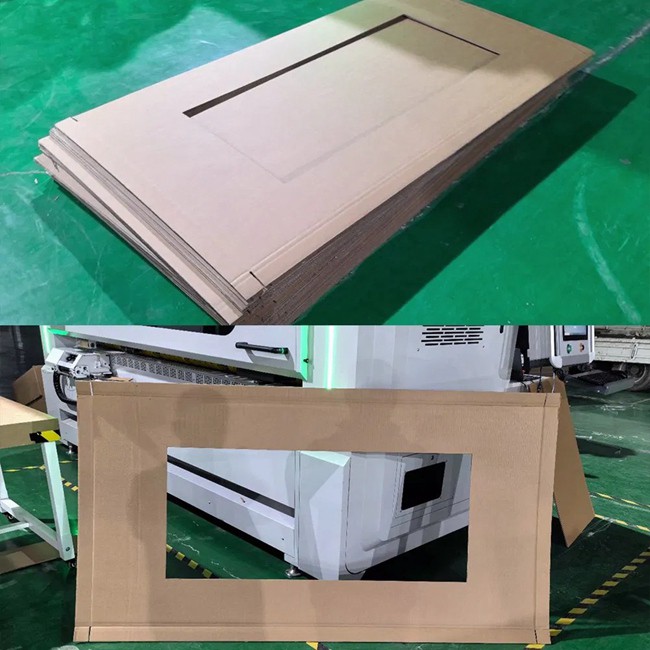

1. Packaging: Produce corrugated boxes, molded pulp trays, and anti-static e-commerce packaging.

2. Hygiene Products: High-speed lines for facial tissue, toilet paper, and medical-grade paper products.

3. Specialty Papers: Release liners, labels, and conductive papers for electronics.

4. Printing & Publishing: Ultra-smooth coated papers for high-resolution digital printing.

Future-Proof Your Business

Investing in state-of-the-art paper processing machinery isn’t just about upgrading equipment-it’s about embracing a smarter, greener, and more agile manufacturing philosophy. With modular designs that adapt to emerging trends (e.g., e-commerce packaging surges, plastic substitution), these systems ensure that your facility remains competitive in a rapidly evolving market.

By prioritizing precision engineering, resource efficiency, and intelligent automation, next-gen paper processing machinery delivers transformative ROI, empowering manufacturers to meet sustainability targets, satisfy discerning clients, and lead the transition toward a circular economy.

Who We Are?

Ruian Loyal Machinery Co., Ltd. is a trusted manufacturer and supplier specializing in high-quality hydraulic tools, pneumatic equipment, and custom machinery components, established in Ruian City, Zhejiang Province, China. With over a decade of industry experience, we integrate advanced technology, stringent quality control, and a professional R&D team to deliver innovative solutions for global clients across construction, automotive, and industrial maintenance sectors. Our products comply with international certifications, emphasizing durability, precision, and cost-effectiveness, while our customer-centric approach ensures tailored services and reliable after-sales support, fostering long-term partnerships worldwide.

Recommended Products

Recently Viewed

High-speed automatic corrugated carton box machine paperboard cutting machine

High-speed automatic corrugated carton box machine paperboard cutting machine High-efficiency corrugated cardboard machine with cutting function

High-efficiency corrugated cardboard machine with cutting function Exploring the Efficiency and Versatility of Paperboard Machines

Exploring the Efficiency and Versatility of Paperboard Machines The Ultimate Guide to Paperboard Machines: Revolutionizing the Packaging Industry

The Ultimate Guide to Paperboard Machines: Revolutionizing the Packaging Industry Efficient and Reliable Paperboard Machines: Revolutionizing the Packaging Industry

Efficient and Reliable Paperboard Machines: Revolutionizing the Packaging Industry

Contact Us

Ruian Loyal Machinery Co., Ltd.