Welcome!

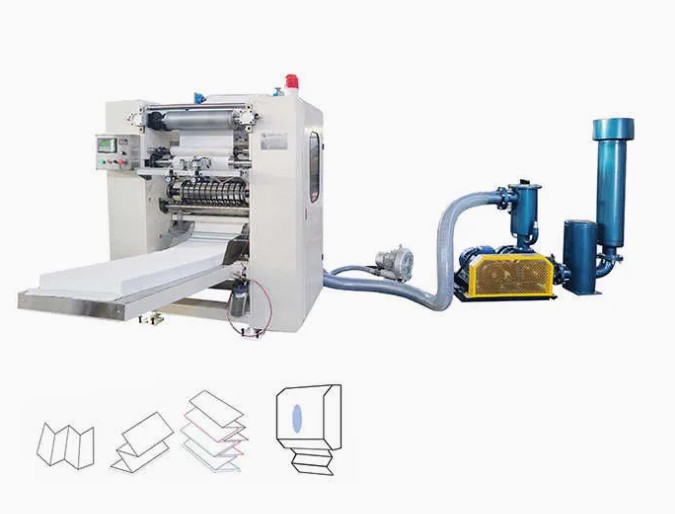

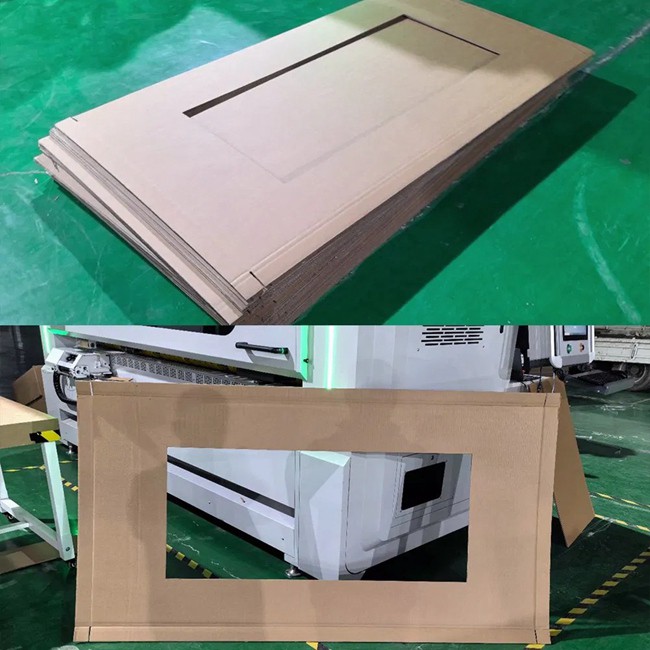

Wholesale price of fully automatic corrugated cardboard forming machine

Basic Info

| Cardboard Density Range | up to 2400g/Sqm | Cardboard Thickness | 2-16mm | Corrugated Board Type | Single/Double/Triple Wall (AAA) |

|---|---|---|---|---|---|

| Driven Type | Electric | Horizontal Cutting Knife | 1 | Machine Category | Carton Box Making Machine |

| Min.Board Size | 300X660mm | Origin | China | Product Certificate | CE Certificate for Box Making Machine |

| Production Capacity | 150 Set/Year | Scoring/Creasing Wheel | 4+4 | Slotting Knife | 2 PCS *500mm Length |

| Specification | 3820(W)* 2060(L)* 1970mm(H) | Type | Automatic Carton Making Machine | ||

Product Description

In the realm of modern packaging, corrugated cardboard stands out as a lightweight, durable, and eco-friendly material used globally to protect goods during storage and transit. At the core of its production lies the corrugated cardboard forming machine—a highly specialized piece of equipment that transforms raw paper into the iconic layered structure of corrugated board. This article delves into the mechanics, components, applications, and environmental benefits of this indispensable machinery.

What is Corrugated Cardboard?

Corrugated cardboard consists of three layers:

Linerboard: Flat outer sheets (typically made from kraft paper).

Medium: A fluted (wavy) inner layer that provides cushioning and strength.

This combination creates a rigid yet lightweight material, ideal for boxes, protective packaging, and displays.

How a Corrugated Cardboard Forming Machine Works

The manufacturing process involves multiple stages to bond the layers and shape the fluted medium:

Paper Unwinding: Rolls of kraft paper (for liners) and recycled paper (for the medium) are loaded onto unwinders.

Corrugation:

The medium paper passes through a corrugating roller unit, where it is steamed, heated, and pressed into a wavy pattern (flutes) using gear-like rollers. Common flute profiles include A, B, C, and E types, each offering different strength and thickness properties.

Adhesive Application:

Starch-based adhesive is applied to the tips of the fluted medium.

Lamination:

The fluted medium is bonded between two linerboards under high pressure and heat, forming a single-face or double-face corrugated board.

Drying:

The board moves through a drying section (hot plates or steam-heated rollers) to cure the adhesive.

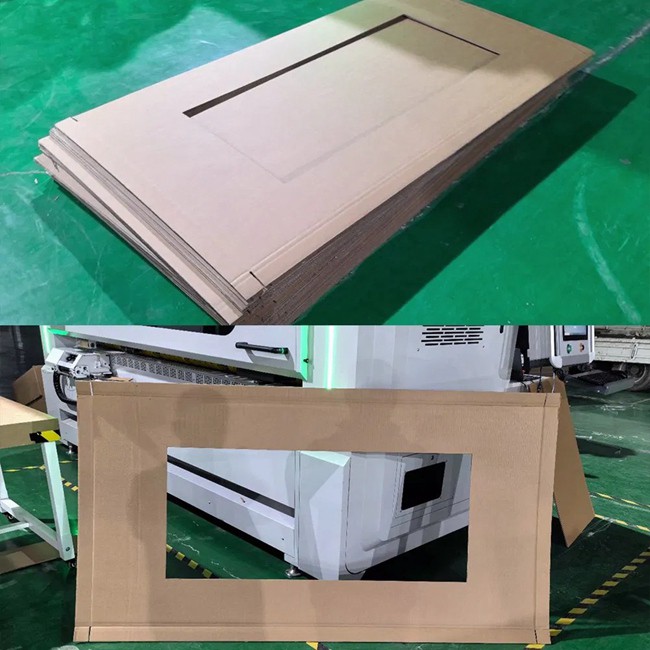

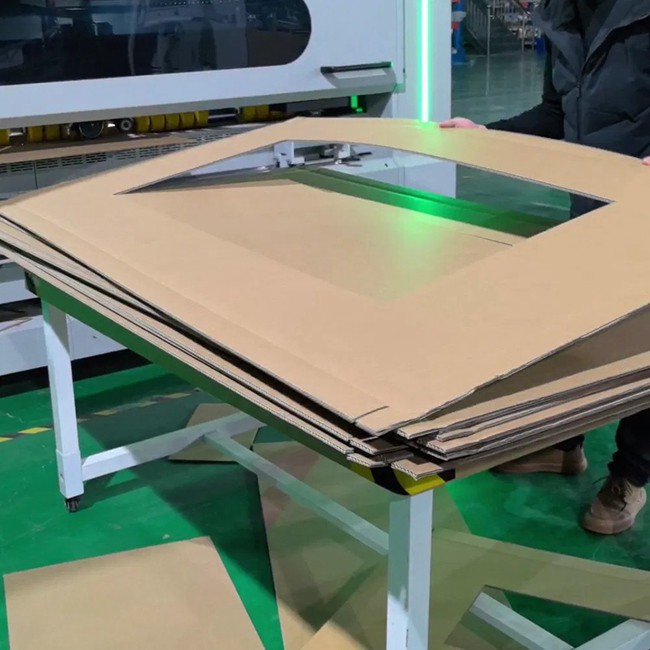

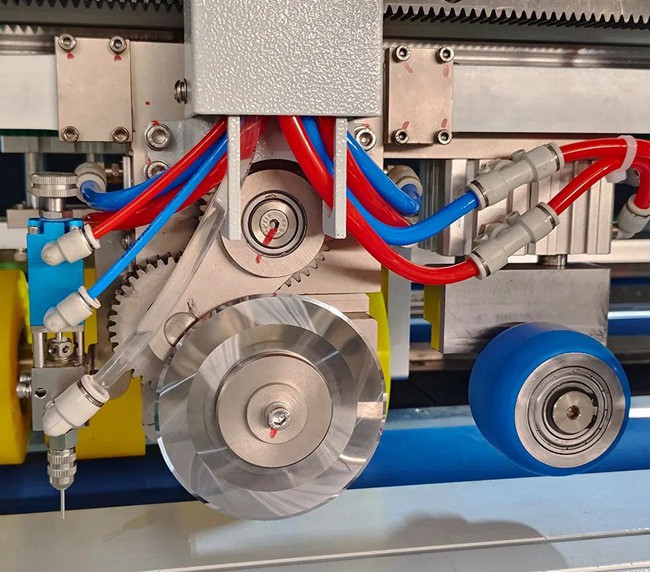

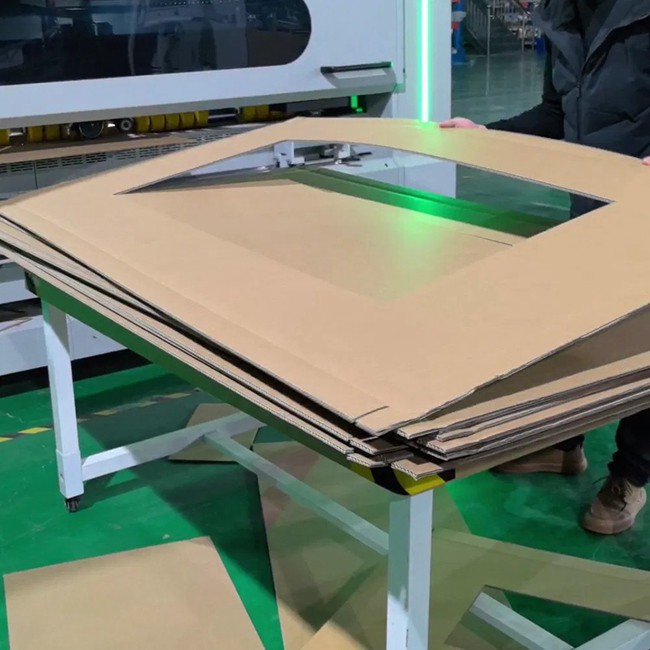

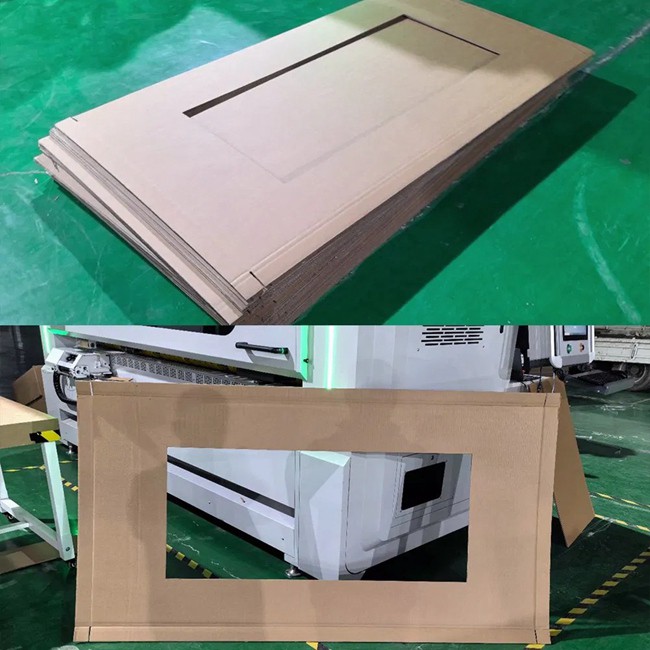

Cutting and Slitting:

Rotary cutters or die-cut units trim the board to desired dimensions and create slots or creases for folding into boxes.

Advanced machines integrate computerized controls to adjust flute type, adhesive quantity, and cutting patterns, ensuring precision and scalability.

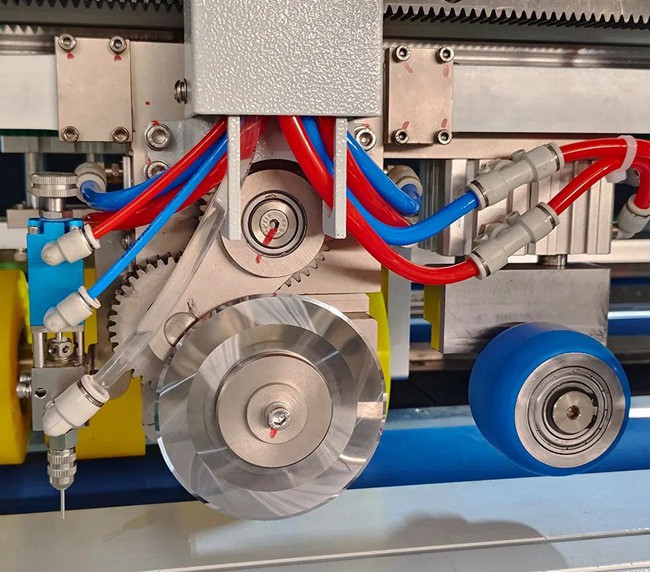

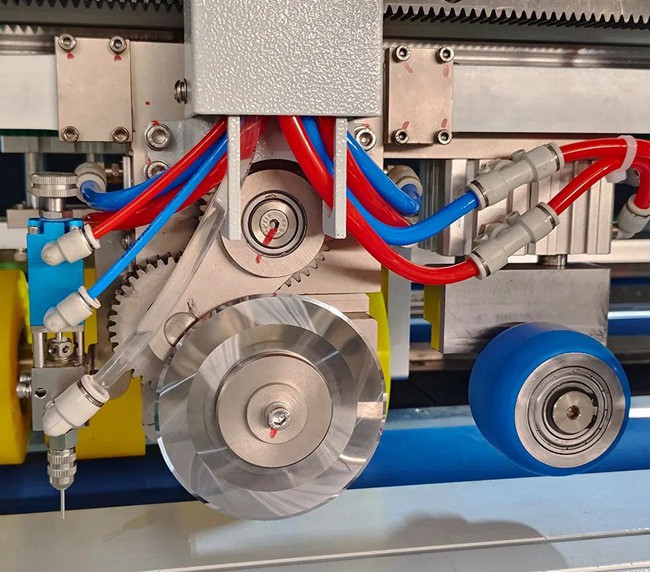

Key Components of the Machine

Corrugating Rolls: Heated rollers that shape the medium into flutes.

Preheater: Condition the paper for optimal adhesion.

Glue Unit: Apply adhesive evenly to the flutes.

Double Backer: Bond the second linerboard to complete the corrugated board.

Cut-Off System: Cut the continuous board into sheets or blanks.

PLC Control System: Monitor temperature, speed, and alignment for consistent quality.

Applications of Corrugated Cardboard

Corrugated cardboard is ubiquitous in:

Shipping Boxes: Protect products in e-commerce and logistics.

Retail Packaging: Custom-printed boxes for branding.

Displays: Lightweight shelves or stands for stores.

Food Packaging: Grease-resistant and ventilated designs for perishables.

Industrial Cushioning: Insert to safeguard fragile items.

Advantages of Corrugated Cardboard Forming Machines

High-Speed Production: Capable of producing thousands of square meters per hour.

Customization: Adjustable flute profiles, sheet sizes, and printing options.

Material Efficiency: Minimize waste through precise cutting and recyclable inputs.

Sustainability: Uses renewable materials (paper) and eco-friendly adhesives.

Cost-Effectiveness: Lower logistics costs due to the material’s lightweight nature.

About Us

Ruian Loyal Machinery Co., Ltd located in Ruian city, southeast of China, specializing in the slitting machine, die cutting machine, printing machine making for more than 10 years in the application of label /flexible packing /electric protector film/new energy and paper industry. RaLoyal have been always devoted to provide a global solution to the demands of markets in constant development with competitive and tailored equipment including the latest solutions in innovation, technology and sustainability for customers. We have set agent in Germany, Venezuela, which can provide immediate technical support available to minimize the waiting time for customers. We deeply believe that Raloyal will become your loyal partner and supplier once we have a chance to start the cooperation!

Recommended Products

Recently Viewed

High-speed automatic corrugated carton box machine paperboard cutting machine

High-speed automatic corrugated carton box machine paperboard cutting machine High-efficiency corrugated cardboard machine with cutting function

High-efficiency corrugated cardboard machine with cutting function Exploring the Efficiency and Versatility of Paperboard Machines

Exploring the Efficiency and Versatility of Paperboard Machines The Ultimate Guide to Paperboard Machines: Revolutionizing the Packaging Industry

The Ultimate Guide to Paperboard Machines: Revolutionizing the Packaging Industry Efficient and Reliable Paperboard Machines: Revolutionizing the Packaging Industry

Efficient and Reliable Paperboard Machines: Revolutionizing the Packaging Industry

Contact Us

Ruian Loyal Machinery Co., Ltd.