Welcome!

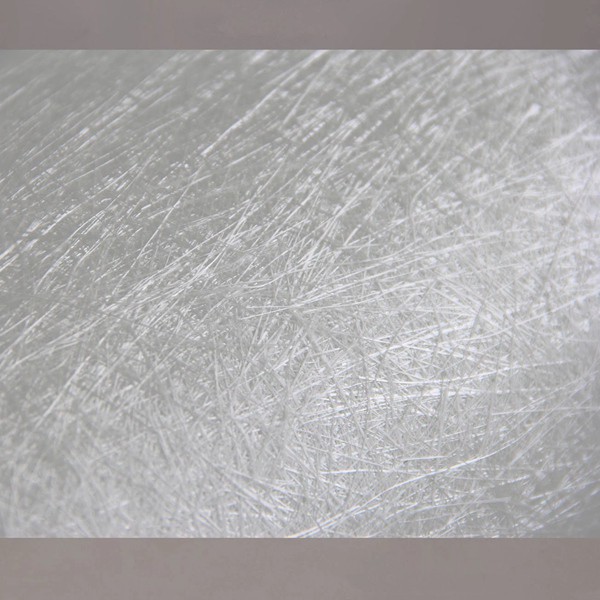

Chinese suppliers Fiber Glass Fibre Fabric Continuous Filament Mat Use Thin Felt for Rtm Process

Product Description

In terms of application, glass fiber felt has a wide range of applications. Firstly, it is often used as insulation material for various heat source equipment, such as pipeline insulation for high-temperature equipment such as coal, electricity, oil, and gas. The insulation effect of glass fiber felt can effectively reduce energy loss and improve the operational efficiency of equipment. In addition, fiberglass felt can also be used for thermal insulation and fire prevention in buildings, providing strong protection for people's living safety. In special places such as laboratories, factories, etc., fiberglass felt can also be used as a sealing, filtering, and insulating material, exerting its multifunctionality.

Fiberglass felt has excellent physical and chemical properties. It has a high heat resistance temperature and can maintain stable performance in high-temperature environments, so it is often used for insulation of various high-temperature equipment. At the same time, fiberglass felt also has good insulation and sound absorption properties, which can effectively reduce energy loss and noise propagation, improve equipment operation efficiency and comfort. In addition, fiberglass felt also has characteristics such as corrosion resistance, insect resistance, and mold resistance, which can maintain stable performance in harsh environmental conditions and extend its service life.

It should be noted that the production of fiberglass felt requires corresponding equipment such as an oven, mold, press, etc. Safety should be taken into account during the production process, such as wearing protective masks and gloves during processing. In addition, with the continuous development of technology, the application of glass fiber felt is also constantly expanding. For example, researchers used plasma chemical vapor deposition technology to grow nitrogen doped vertically structured graphene on the surface of glass fiber felt, preparing graphene glass fiber felt with adjustable infrared radiation performance, providing a new solution for fields such as photothermal oil recovery.

In terms of production technology, the production process of fiberglass felt includes steps such as impregnation, molding, compression, curing, exhaust, and polishing. Firstly, soak the fiberglass cloth or felt in the resin to allow the fibers to fully absorb the resin. Then, place the impregnated fiberglass cloth or felt into the prefabricated mold and machine press it into shape. Next, by compressing to remove excess resin and air, the glass fibers are made tighter. Subsequently, the compressed glass fiber is placed in an oven or cured at room temperature until the resin is completely hardened. Finally, perform exhaust and polishing treatment to make the product surface smooth and beautiful.

Recommended Products

Recently Viewed

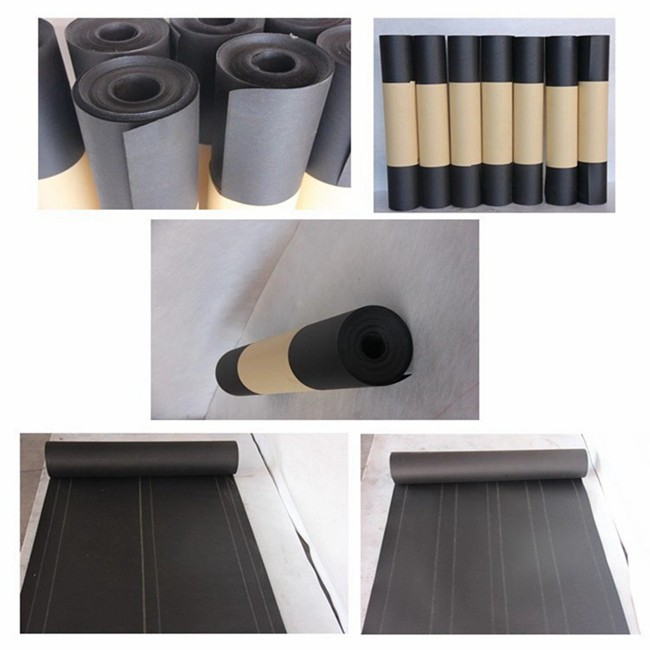

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper Hot Selling R13 R19 Fiberglass Thermal Insulation Roll

Hot Selling R13 R19 Fiberglass Thermal Insulation Roll High Quality Wooden Roofing Materials Black Asphalt Tar Paper

High Quality Wooden Roofing Materials Black Asphalt Tar Paper Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance

Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Contact Us

Changzhou Tianma Group Co., Ltd.