Welcome!

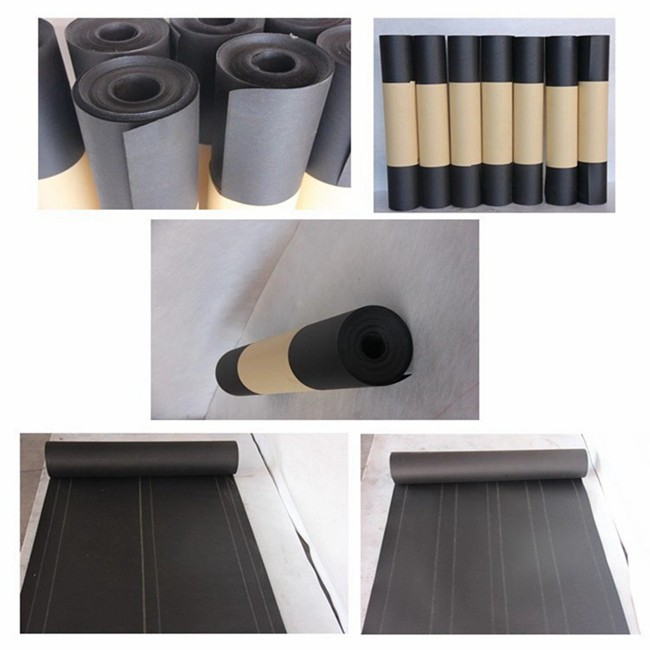

Chinese suppliers Fiberglass Flowmat 300/180/300 PP Core Mat Sandwich Mat for Roof

Product Description

Fiberglass felt has become an indispensable and important material in industrial production and daily life due to its excellent physical and chemical properties and wide range of applications. With the continuous progress of technology and the expansion of application fields, it is believed that glass fiber felt will play a more important role in the future and contribute more strength to the development of human society.

With the advancement of technology, the application fields of glass fiber felt are constantly expanding. For example, in the aerospace field, fiberglass felt is widely used in the manufacturing of aircraft, rockets, and other aircraft due to its lightweight and high-strength characteristics. In the field of environmental protection, glass fiber felt is also used as a filtering material for waste gas treatment equipment, effectively removing harmful substances in waste gas and protecting the environment.

Fiberglass felt has excellent physical and chemical properties. It has a high heat resistance temperature and can maintain stable performance in high-temperature environments, so it is often used for insulation of various high-temperature equipment. At the same time, fiberglass felt also has good insulation and sound absorption properties, which can effectively reduce energy loss and noise propagation, improve equipment operation efficiency and comfort. In addition, fiberglass felt also has characteristics such as corrosion resistance, insect resistance, and mold resistance, which can maintain stable performance in harsh environmental conditions and extend its service life.

In terms of production technology, the production process of fiberglass felt includes steps such as impregnation, molding, compression, curing, exhaust, and polishing. Firstly, soak the fiberglass cloth or felt in the resin to allow the fibers to fully absorb the resin. Then, place the impregnated fiberglass cloth or felt into the prefabricated mold and machine press it into shape. Next, by compressing to remove excess resin and air, the glass fibers are made tighter. Subsequently, the compressed glass fiber is placed in an oven or cured at room temperature until the resin is completely hardened. Finally, perform exhaust and polishing treatment to make the product surface smooth and beautiful.

Glass fiber felt, as a non-woven material composed of continuous glass fibers, plays an important role in multiple industrial fields due to its unique physical and chemical properties. This article will provide a detailed introduction to the characteristics, applications, and production processes of fiberglass felt, in order to give readers a deeper understanding of this material.

Recommended Products

Recently Viewed

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper Hot Selling R13 R19 Fiberglass Thermal Insulation Roll

Hot Selling R13 R19 Fiberglass Thermal Insulation Roll High Quality Wooden Roofing Materials Black Asphalt Tar Paper

High Quality Wooden Roofing Materials Black Asphalt Tar Paper Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance

Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Contact Us

Changzhou Tianma Group Co., Ltd.