Welcome!

High quality Round Steel Bar Building Materials Reinforced Bar

Product Description

The production process of threaded steel mainly includes steps such as steelmaking, rolling, cooling, straightening, cutting, and inspection. Firstly, qualified molten steel is produced through blast furnace smelting, and then it is continuously cast into steel billets through a continuous casting machine. Next, the steel billet is heated to an appropriate temperature in the heating furnace and then sent to the rolling mill for rolling. During the rolling process, the steel is extruded and stretched by the mold to form a threaded shape with longitudinal and transverse ribs. After rolling is completed, the steel needs to undergo subsequent treatments such as cooling, straightening, and cutting, and finally pass quality inspection before leaving the factory.

Due to the presence of longitudinal and transverse ribs (spiral, herringbone, and crescent) on the surface of rebar, it significantly increases the bonding strength with concrete. This special structure enables the rebar to form a strong gripping force in concrete, effectively preventing problems such as concrete cracking and steel corrosion. At the same time, threaded steel has high strength and toughness, and can withstand large tensile and compressive forces, providing stable and reliable support for buildings.

The Chinese steel reinforcement industry has made significant progress. With the acceleration of urbanization and the continuous improvement of infrastructure construction, the demand for steel bars continues to grow. At the same time, with the increase of environmental protection requirements and the intensification of market competition, the steel reinforcement industry is also facing pressure of transformation and upgrading. The steel reinforcement industry will increase its efforts in technological innovation and industrial upgrading, and enhance its overall competitiveness through measures such as introducing advanced technology and equipment, optimizing production processes, improving product quality and service levels. At the same time, the steel reinforcement industry will actively participate in international cooperation and competition, expand the international market, and promote China's steel reinforcement to go global.

The production process of steel bars mainly includes steps such as raw material treatment, heat treatment, treatment and cutting, as well as quality inspection and packaging. Firstly, coarse steel ingots are produced by smelting in a blast furnace, and steel billets that meet the requirements are obtained through continuous casting in a continuous casting machine. Then, the steel billet is sent into the heating furnace for pretreatment to reach the appropriate processing temperature. Next, the steel billet enters the rolling mill for rolling, undergoes processes such as rough rolling and finishing rolling, and finally obtains steel bars with the required diameter. During the rolling process, steel bars also need to undergo water quenching and cold drawing treatments to achieve certain strength and diameter requirements. Finally, the steel bars need to undergo surface treatment and quality inspection to ensure that the products meet the standards before packaging.

As an indispensable and important material in modern building structures, steel bars have made tremendous contributions to human construction due to their unique physical properties and wide application fields. From high-rise buildings to bridges and roads, from underground pipe galleries to water conservancy projects, the presence of steel bars is everywhere. With its strong load-bearing capacity and stability, it has become the cornerstone supporting modern civilization.

Recommended Products

Recently Viewed

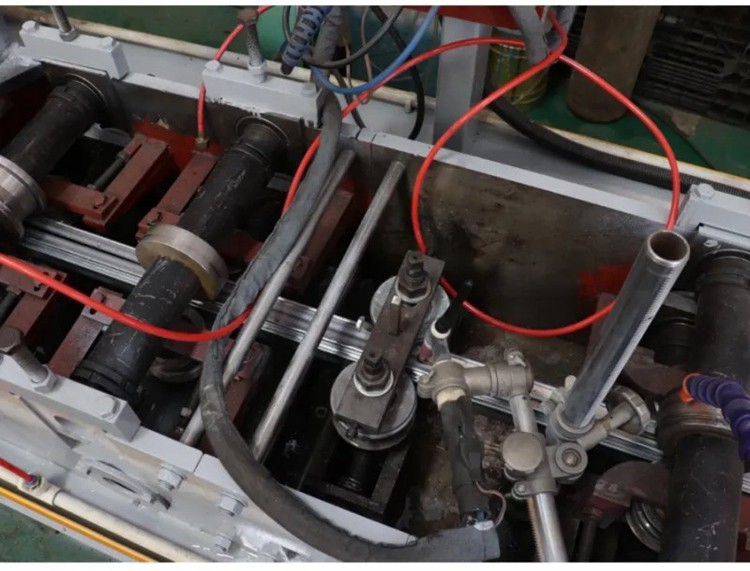

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.