Welcome!

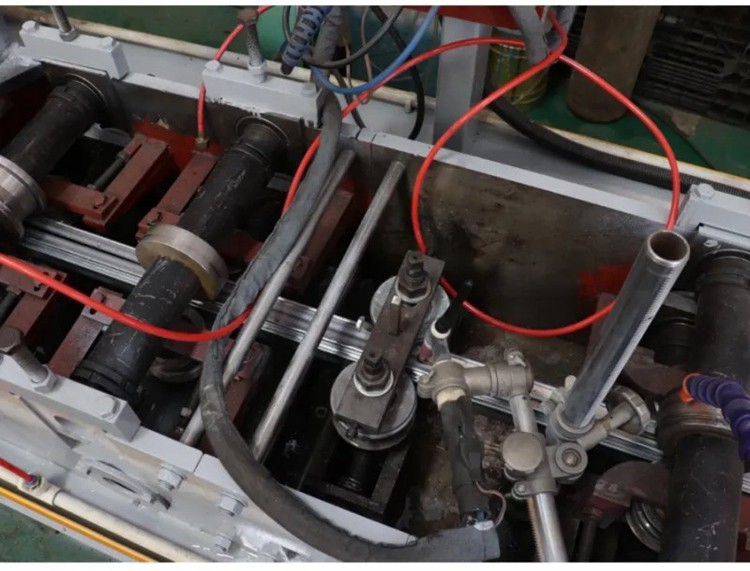

High Speed Metal Profile Roll Cold Forming Machine

Product Description

Roll forming machine, as an important metal processing equipment, has a series of significant characteristics that make it widely used in industrial production.

Roll forming machines can achieve continuous and automated production processes, greatly improving production efficiency. By adjusting the speed and pressure of the rollers, precise control of production speed can be achieved to meet different production needs.

Roll forming machines can ensure the dimensional and shape accuracy of products, meeting strict quality requirements. Due to the uniform plastic deformation of the metal material during the rolling process, the product has excellent mechanical properties and surface quality.

Roll forming machines can process various metal materials such as steel, aluminum, copper, as well as plates of different thicknesses and specifications. By replacing different roller molds, it is possible to adapt to the production needs of products with different shapes and sizes.

Roll forming machines have low energy consumption during the production process and do not generate a large amount of waste and pollutants. Compared to other molding methods, roll forming machines have significant advantages in production efficiency and material utilization.

The operation interface of the roll forming machine is simple and easy to understand, making it easy for operators to get started. Equipment maintenance is relatively simple, only requiring regular inspections and replacement of worn parts.

The roll forming machine is designed with safety in mind, such as setting up emergency stop buttons, safety protection devices, etc. Operators need to receive professional training and strictly follow safety operating procedures to ensure safety during the production process.

Roll forming machines can be combined with other automation equipment and intelligent control systems to achieve automated production and intelligent monitoring. By introducing advanced technologies such as sensors and PLCs, real-time monitoring of production status can be achieved, improving production efficiency and product quality.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.