Welcome!

corrugated sheet rolling machine

Product Description

The corrugated plate rolling machine is a special equipment for manufacturing corrugated plates. It is widely used in the construction industry, including rail transit, subway, roof trusses and other fields. Corrugated plates have become one of the commonly used materials in modern construction due to their good load-bearing capacity and economy.

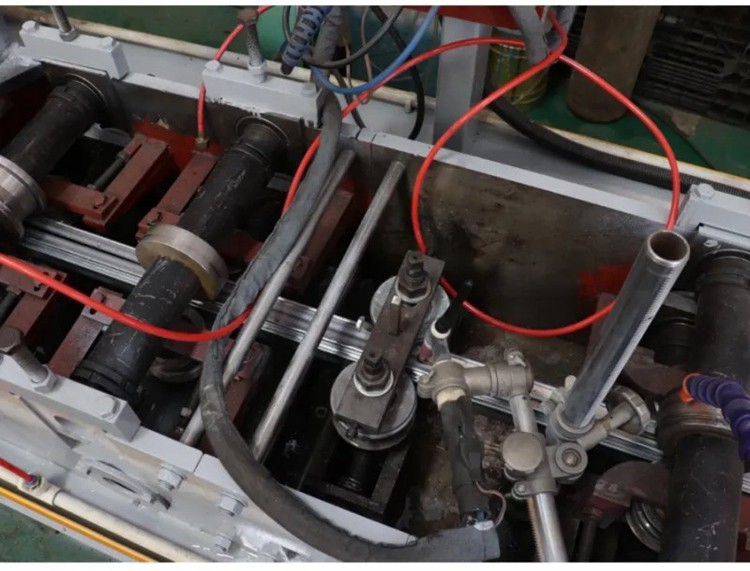

The corrugated plate rolling machine processes metal sheets into plates with specific corrugated shapes through continuous curling and forming processes. This machine usually consists of a feeding mechanism, a forming mechanism, a shearing mechanism and a discharging mechanism. During operation, the metal sheet enters the forming area through the feeding mechanism, and is continuously acted upon by multiple forming rollers to form the desired corrugated shape. Finally, the shearing mechanism cuts it off according to the predetermined length to complete the manufacture of the corrugated plate.

Types of corrugated plate rolling machines

Corrugated plate rolling machines can be divided into many types according to their functions and application ranges:

Single-layer corrugated plate rolling machine: mainly used to produce single-layer corrugated plates, with simple structure and convenient operation.

Double-layer corrugated plate rolling machine: can produce double-layer corrugated plates at the same time, improving production efficiency.

Three-ring corrugated plate rolling machine: suitable for producing plates with three-ring corrugated shapes, suitable for special construction needs.

Adjustable corrugated plate rolling machine: by adjusting the position of the forming roller, corrugated plates with different wave heights and wave distances can be produced.

Product advantages

Improve material utilization: The corrugated plate rolling machine can accurately control the forming process of the plate and reduce material waste.

Enhanced structural stability: The corrugated shape increases the stiffness and strength of the board, improving structural stability.

Improve production efficiency: high degree of automation, strong continuous production capacity, suitable for large-scale production.

Reduce costs: Compared with hand-made corrugated sheets, using a plate rolling machine can significantly reduce production costs.

Specifications

The specifications of corrugated sheet rolling machines vary by model and manufacturer, but generally include the following aspects:

Maximum processing width: refers to the maximum sheet width that the machine can process, usually in millimeters (mm).

Maximum processing thickness: refers to the maximum sheet thickness that the machine can process, usually in millimeters (mm).

Forming speed: refers to the speed at which the machine forms corrugated sheets, usually in meters per minute (m/min).

Power: refers to the total power of the machine, usually in kilowatts (kW).

Corrugation parameters: including wave height, wave distance, etc., which determine the shape and performance of the corrugated sheet.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.