Welcome!

Plate roller machine manufacturer direct sales

Product Description

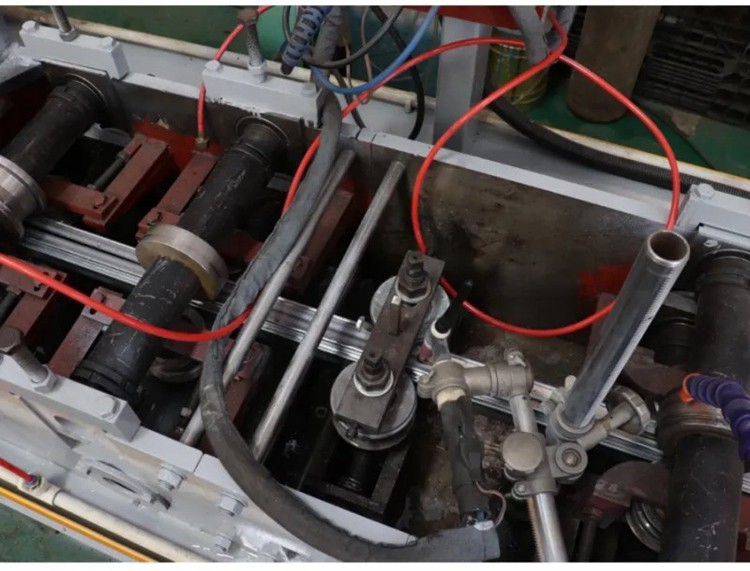

Plate rolling machine, also known as metal plate rolling machine, is a mechanical equipment used to bend metal sheets into the desired shape. It presses metal sheets into cylindrical, conical or other complex shapes through the synergistic action of three or four rollers. Plate rolling machines are widely used in industries such as construction, shipbuilding, aerospace, and automobile manufacturing, and are indispensable equipment in modern metal processing.

Product classification

Plate rolling machines are mainly divided into the following categories according to the number and function of rollers:

Two-roller rolling machine: suitable for simple bending and forming, usually used for smaller plates and lower production requirements.

Three-roller rolling machine: the most common type, capable of handling plates of various thicknesses and diameters, suitable for most industrial applications.

Four-roller rolling machine: with higher precision and flexibility, suitable for the forming of complex shapes and production with high precision requirements.

Product advantages

Compared with other metal forming equipment, the plate rolling machine has the following significant advantages:

High precision and repeatability: The plate rolling machine can ensure that the shape and size of each molding are highly consistent, meeting the production needs of high precision requirements.

Strong adaptability: able to handle plates of different thicknesses and diameters, suitable for molding a variety of materials and shapes.

Efficient production: The automated control system and advanced roller design enable the plate rolling machine to efficiently complete the forming task, greatly improving production efficiency.

Low rebound: The sheet rolling machine produces less rebound during the forming process, ensuring the stability and consistency of the finished product.

High bending quality: Through precise roller control and adjustment, the plate rolling machine can achieve high-quality bending forming with a smooth and flawless surface.

Cost-Effectiveness: Compared to other metal forming methods, sheet rolling machines are less expensive to use and easy to maintain, making them more economical to use over the long term.

Low energy consumption: The plate rolling machine requires less energy during the forming process and consumes less energy than other equipment such as press brakes.

Automated control: Modern sheet rolling machines are equipped with automatic roller profile adjustment and integrated measuring devices, further improving production efficiency and product quality.

Plate rolling machines have become indispensable equipment in modern metal processing due to their high precision, efficiency, adaptability and cost-effectiveness. With the continuous advancement of technology, plate rolling machines will play a more important role in future industrial production.

Recommended Products

Recently Viewed

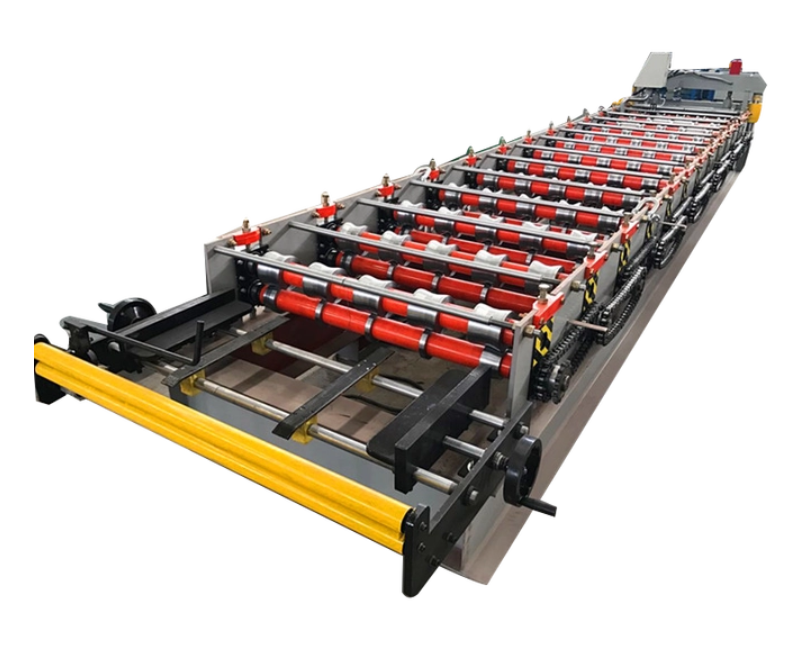

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.