Welcome!

Hot Selling R13 R19 Fiberglass Thermal Insulation Roll

Product Description

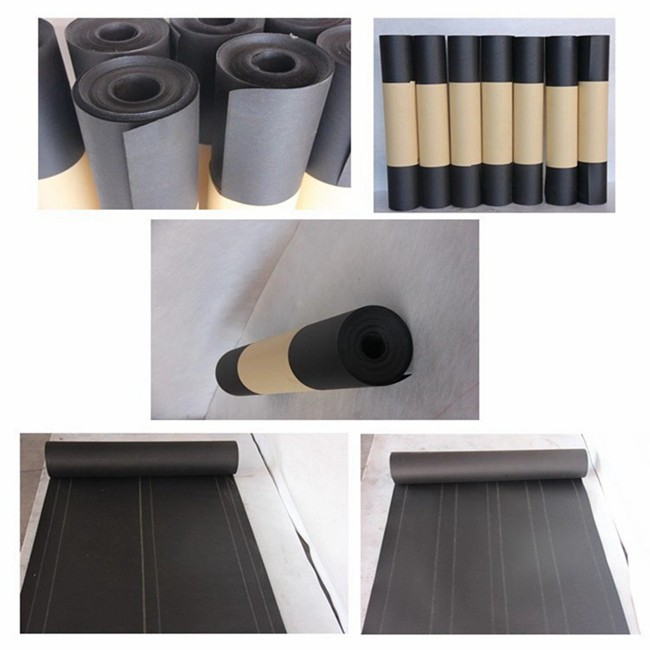

The production process of asphalt felt paper mainly includes preparing raw materials (such as asphalt, paper, accelerators, stabilizers, etc.), operating equipment (such as asphalt melting pot, coating mixer, rolling mill, etc.), and specific process flow. During the production process, various raw materials are mixed in proportion, stirred evenly by a mixer, and then pressed into rolls or processed into felt paper of the required thickness by a rolling mill. Subsequently, the oil felt paper is subjected to heating, embossing, and other treatments to increase its anti slip performance and aesthetic appeal. Finally, the processed felt paper is cut and packaged to complete the production process.

There are many types of oil felt paper, which can be divided into petroleum asphalt felt, coal asphalt felt, low-temperature resistant felt, powder faced felt, sand faced felt, colored sand faced felt, mineral wool paper felt, asphalt glass cloth felt, metal foil felt, hot-melt felt, self-adhesive felt, flame retardant felt, etc. according to the type of asphalt and spreading fabric, tire base material, functional characteristics, etc. Among them, petroleum asphalt felt can be divided into three specifications according to their grades: 200, 350, and 500. Each specification of felt has its specific application scenarios and performance characteristics.

Recommended Products

Recently Viewed

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper Hot Selling R13 R19 Fiberglass Thermal Insulation Roll

Hot Selling R13 R19 Fiberglass Thermal Insulation Roll High Quality Wooden Roofing Materials Black Asphalt Tar Paper

High Quality Wooden Roofing Materials Black Asphalt Tar Paper Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance

Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Contact Us

Huai An Jiuzhong New Material Co., Ltd.