Welcome!

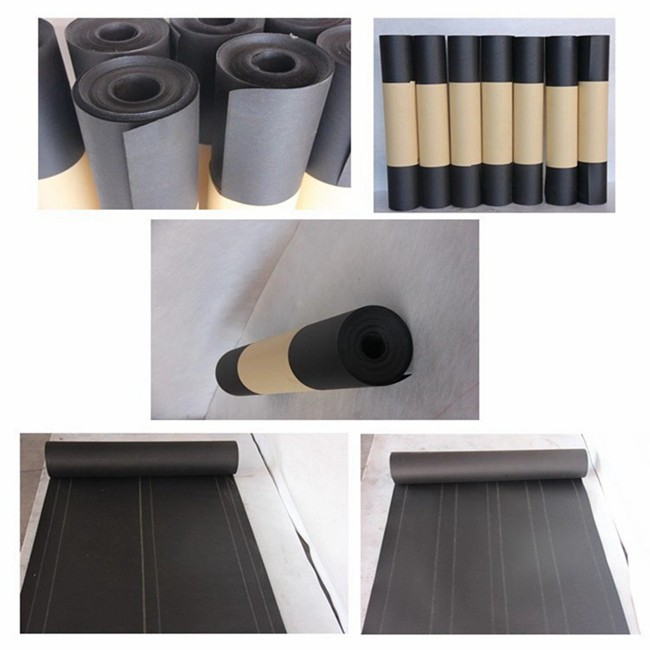

Hot Selling Wooden Roofing Materials Black Asphalt Tar Paper

Product Description

Asphalt felt paper is mainly used as an isolation layer and temporary protective layer material in waterproof construction to prevent damage to the finished waterproof layer during construction. It is widely used for waterproofing and moisture-proof treatment of roofs, basements, walls, floors and other parts. In addition, oil felt paper can also be used for moisture-proof protection of pipe galleries, packaging materials, and the lower layer of multi-layer waterproof layers. Oil felt paper should be stored in a dry and ventilated environment, avoiding direct sunlight and rain. During transportation and storage, care should be taken to prevent damage or deformation.

Asphalt glass cloth felt is a waterproof material with excellent performance and wide application. During the construction process, relevant specifications and standards should be strictly followed to ensure construction quality and waterproofing effect. Architectural asphalt felt paper, also known as felt or oil felt, is a widely used building waterproofing material. Building asphalt felt paper is an important building waterproofing material with broad application prospects and market demand. During use, relevant specifications and requirements should be strictly followed to ensure its waterproof effect and service life.

Construction precautions

Grassroots treatment: Before construction, the base should be thoroughly cleaned and treated to ensure that it is flat, clean, free of oil stains and loose materials.

Laying technique: When laying asphalt glass cloth felt, attention should be paid to the overlap width and overlap method between the rolls to ensure a tight bond between the rolls and the integrity of the waterproof layer.

Temperature control: During the construction process, the temperature and viscosity of the asphalt should be strictly controlled to ensure that the asphalt can be evenly coated on the fiberglass fabric and form a good bonding effect.

Post maintenance: After construction is completed, necessary maintenance and protection should be carried out on the waterproof layer to avoid damage or destruction.

Asphalt glass cloth and felt are widely used in waterproofing projects in fields such as construction, transportation, and water conservancy. For example, in waterproofing treatment of roofs, basements, tunnels, bridges, and other areas, asphalt glass cloth and felt play an important role. In addition, it can also be used to make waterproof materials such as waterproof rolls and waterproof coatings. In the production process, glass fiber fabric is first prepared, and then asphalt is uniformly coated on the glass fiber fabric through impregnation process. After a series of treatments such as heating, rolling, etc., asphalt is tightly bonded with glass fibers to form a roll with a certain thickness and strength.

The leakage of asphalt glass cloth and felt mainly occurs at the through wall pipe, bolt, deformation joint, and roll joint. These special areas have poor waterproof base treatment, loose structure, and loose leveling layer closure; The edge of the additional layer of the coil is not tightly closed, and the cutting of the coil is irregular; Poor twisting and compression of the deformation joint waterproof strip, structural deformation, and other reasons cause water leakage at the deformation joint; The joint rolls constructed successively at the joint of asphalt glass cloth and asphalt felt have been damaged, and the adhesion is not tight, resulting in water leakage. During construction, standardized treatment methods should be adopted according to different special parts. During operation, the roll material should be carefully cut according to its shape, and the edges should be flattened and tightly bonded. After completing the additional layer paving in these parts, careful inspection should be carried out to ensure strict acceptance.

Recommended Products

Recently Viewed

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper

Hot Selling Self-Adhesive Waterproof Roll Sbs Modified Asphalt Felt Paper Hot Selling R13 R19 Fiberglass Thermal Insulation Roll

Hot Selling R13 R19 Fiberglass Thermal Insulation Roll High Quality Wooden Roofing Materials Black Asphalt Tar Paper

High Quality Wooden Roofing Materials Black Asphalt Tar Paper Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance

Factory Sypplier Bitumen Roofing Felt Paper with Enhanced Weather Resistance Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Factory Sypplier R13 R19 Fiberglass Thermal Insulation Roll

Contact Us

Huai An Jiuzhong New Material Co., Ltd.