Welcome!

plate roller machine for sale

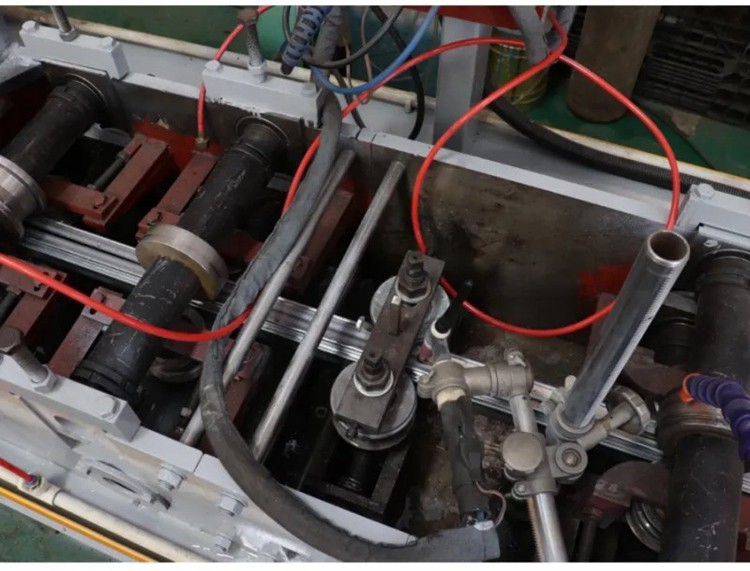

Product Description

Plate rolling machine is a kind of equipment that uses working rollers to bend and shape sheet materials. It can form parts of different shapes such as cylindrical parts and conical parts. It is a very important processing equipment. The working principle of the plate rolling machine is to use external forces such as hydraulic pressure and mechanical force to move the working rollers, so as to bend or roll the sheet. According to the rotational movement and position change of working rollers of different shapes, oval parts, arc parts, cylindrical parts and other parts can be processed.

Types of plate rolling machine

Due to different fields of use, plate rolling machines are of different types. According to the number of rollers, they are divided into three-roller plate rolling machine and four-roller plate rolling machine. Three rollers are divided into symmetrical three-roller plate rolling machine, horizontal downward adjustment three-roller plate rolling machine, arc downward adjustment plate rolling machine, upper roller universal three-roller plate rolling machine, hydraulic CNC plate rolling machine. From the transmission point of view, it is divided into mechanical type and hydraulic type. In terms of the development of plate rolling machine, the upper roller universal type is the most backward, the horizontal downward adjustment type is slightly advanced, and the arc downward adjustment type is the most advanced.

Three-roller plate rolling machines include 1. mechanical type and 2. hydraulic type

1. Mechanical three-roller plate rolling machines are divided into symmetrical and asymmetrical types.

Mechanical three-roller symmetrical type

Performance characteristics of mechanical three-roller symmetrical plate rolling machine: The structure of the machine is three-roller symmetrical type. The upper roller makes vertical lifting motion in the central symmetrical position of the two lower rollers, which is obtained through the screw screw nut worm gear transmission. The two lower rollers make rotational motion, and the output gear of the reducer is meshed with the lower roller gear to provide torque for the rolled plate. The disadvantage of this machine is that the end of the plate needs to be pre-bent with the help of other equipment.

Mechanical three-roller asymmetric type

Main features of mechanical three-roller asymmetric plate rolling machine: The structure of the machine is three-roller asymmetric type. The upper roller is the main drive, and the lower roller moves vertically to clamp the plate, and meshes with the upper roller gear through the lower roller gear, and serves as the main drive at the same time; the side roller makes tilting lifting motion, which has the dual functions of pre-bending and rolling. Compact structure, easy operation and maintenance.

2. Hydraulic type

The main features of the hydraulic three-roller symmetrical plate rolling machine: the upper roller of the machine can be lifted vertically, and the hydraulic transmission of vertical lifting is obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod; the lower roller is driven for rotation, and the output gear of the reducer is meshed to provide torque for the plate rolling. There is a roller at the bottom of the lower roller, which can be adjusted. The upper roller is in the shape of a drum, which improves the straightness of the product and is suitable for ultra-long specifications of various cross-sectional shapes of tanks.

It is an upward-adjustable symmetrical three-roller plate rolling machine, which can roll metal plates into round, arc and conical workpieces within a certain range. The two lower rollers of this model are active rollers, and the upper roller is a driven roller. It is widely used in shipbuilding, boilers, aviation, hydropower, chemical industry, metal structure and machinery manufacturing industries.

It is suitable for bending and deforming metal plates, and can roll round, arc and conical workpieces within a certain range, and has the function of pre-bending the end of the plate. The two lower rollers of this model are active rollers that can move horizontally, and the upper roller is a driven roller that can move up and down. The movement mode is mechanical and hydraulic, and the drive shaft is connected by a universal coupling.

Safe operation

Usually, the operating efficiency and failure rate of mechanical equipment are closely related to the operator. As an operator of dangerous equipment, you should know more about relevant knowledge to effectively avoid some accidents caused by operator's misoperation or accidents. Let's learn about the detailed safety requirements of plate rolling machine operation.

First of all, the operator should tidy up the working environment before operation to maintain a good operating environment. At the same time, the operator's clothes must be neat to avoid the corners of clothes being rolled into the roller during the operation. During the work, it must be noted that the operator can only stand on both sides of the workpiece, which is the most reasonable position. If you need to adjust the roundness of the measurement during the operation, you must stop the machine and operate it. It is forbidden to operate during the operation. A certain margin should be left when the workpiece is processed.

When measuring the roundness of the size, the operator is prohibited from standing on the rolled cylinder, and it is forbidden to stand on the workpiece to be processed. For some difficult workpieces: such as thicker, larger diameter, higher hardness or strength of raw materials, etc., a small amount of work should be done at the same time and multiple times to achieve the desired effect. For some workpieces with smaller diameters, they should be placed in the middle of the rollers for rolling.

Notes

1. Clean the plate rolling machine components, especially the connection parts;

2. When assembling the plate rolling machine, follow the principle of assembling from the inside to the outside and from the bottom to the top;

3. During assembly, give priority to assembling with the same tooling or assembling in the same direction;

4. During the assembly process, the design drawings must be strictly followed and the dimensions and specifications must be strictly controlled.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.