Welcome!

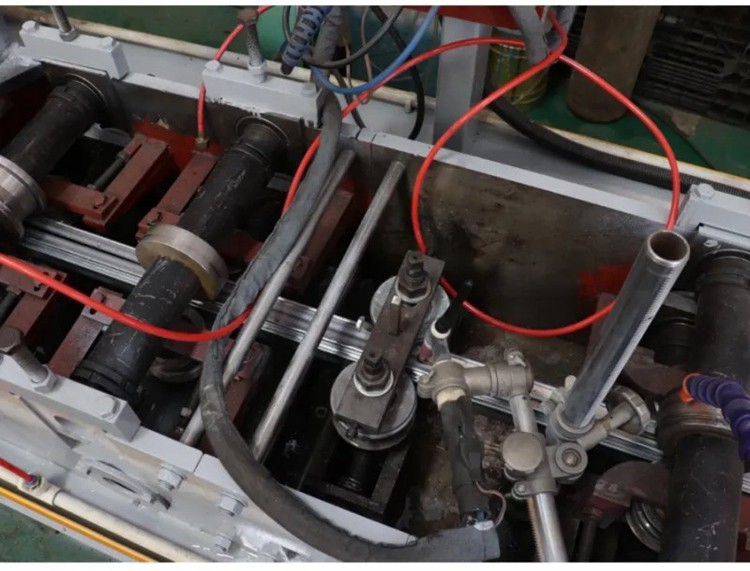

roll plate bending machine china

Product Description

Types of plate rolling machines

The plate rolling machines can be divided into many types according to their structure and purpose, mainly including the following:

Three-roller plate rolling machine:

Symmetrical three-roller plate rolling machine: The upper roller is located in the middle of the two lower rollers, suitable for rolling cylindrical workpieces.

Horizontal downward adjustment three-roller plate rolling machine: The lower roller can move horizontally, suitable for rolling conical workpieces.

Arc downward adjustment plate rolling machine: The lower roller can move along the arc, suitable for rolling arc workpieces.

Four-roller plate rolling machine:

The four-roller plate rolling machine has four rollers, which can achieve more complex curling shapes and is suitable for rolling conical and arc workpieces.

Mechanical plate rolling machine:

Mechanical three-roller plate rolling machine: The rollers are driven by a mechanical transmission system, suitable for medium and low speed rolling.

Mechanical four-roller plate rolling machine: Also driven by a mechanical transmission system, suitable for medium and low speed rolling.

Hydraulic plate rolling machine:

Hydraulic three-roller plate rolling machine: The rollers are driven by a hydraulic system, suitable for high-speed rolling.

Hydraulic four-roller plate rolling machine: driven by hydraulic system, suitable for high-speed rolling.

Structural features

The structural design of the plate rolling machine determines its working performance and scope of application. The main structural features include:

Roller system:

Three-roller system: includes one upper roller and two lower rollers, the upper roller is fixed and the lower roller is movable, suitable for rolling cylindrical and conical workpieces.

Four-roller system: includes one upper roller and three lower rollers, suitable for rolling more complex shapes.

Transmission system:

Mechanical transmission: the rollers are driven by mechanical parts such as gears and chains, suitable for medium and low speed rolling.

Hydraulic transmission: the rollers are driven by the hydraulic system, suitable for high-speed rolling, with higher precision and stability.

Control system:

Modern plate rolling machines are usually equipped with advanced control systems, including PLC (programmable logic controller) and touch screen operation interface, which can realize automatic operation and precise control.

Precautions

When operating the plate rolling machine, the following matters need to be paid attention to to ensure safe and efficient production:

Preparation before operation:

The operator must carefully read the equipment manual and be familiar with the structure and operation method of the equipment.

Check the lubrication system of the equipment to ensure that all lubrication points are fully lubricated.

Operation procedures:

Operate strictly in accordance with the operating procedures and prohibit overload operation.

When adjusting the roller position and pressure, ensure that the size and shape of the workpiece meet the requirements.

Safe operation:

During operation, it is forbidden to put your hands and feet on the rollers, transmission parts and workpieces.

When multiple people work together, there must be a special person to command to ensure orderly operation.

Maintenance:

Regularly check the wear of the equipment and replace the worn parts in time.

Keep the equipment clean to prevent dust and impurities from entering the equipment.

The plate rolling machine has a wide range of applications in industrial production. It has various types and different structural characteristics, which are suitable for different rolling needs. When operating the plate rolling machine, the operating procedures and safety precautions must be strictly followed to ensure production safety and normal operation of the equipment. Through reasonable maintenance and care, the service life of the equipment can be extended and production efficiency can be improved.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.