Welcome!

Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions

Basic Info

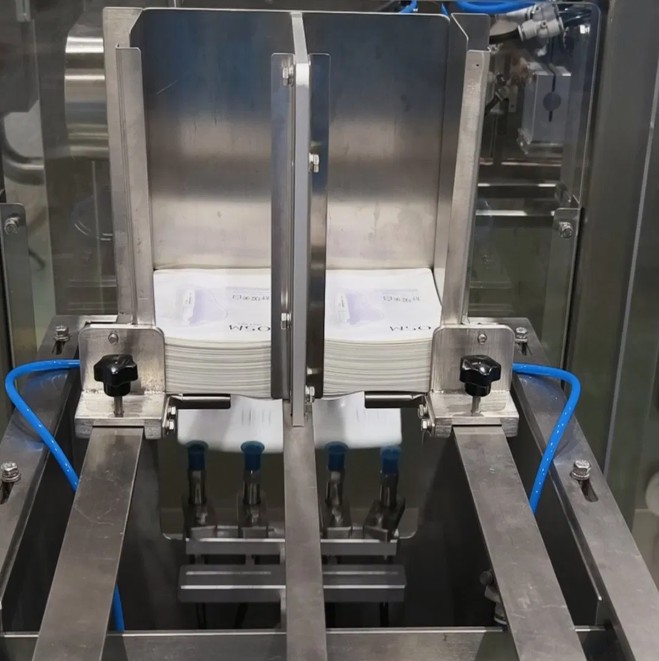

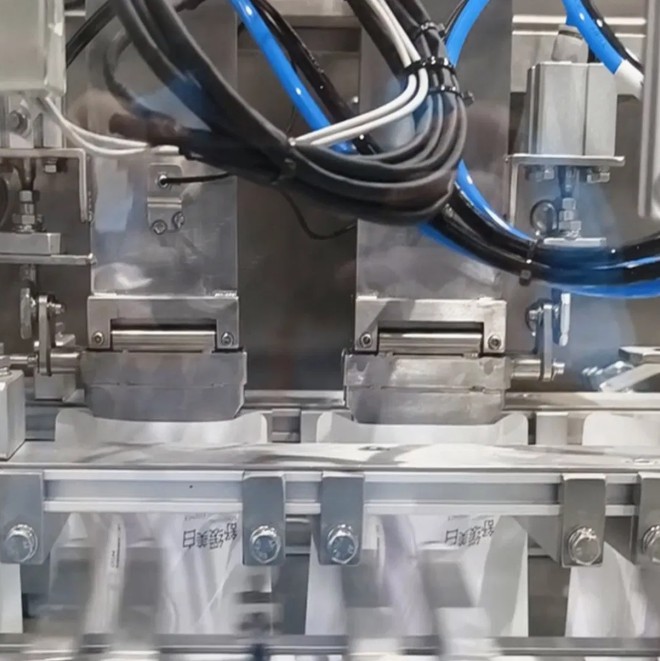

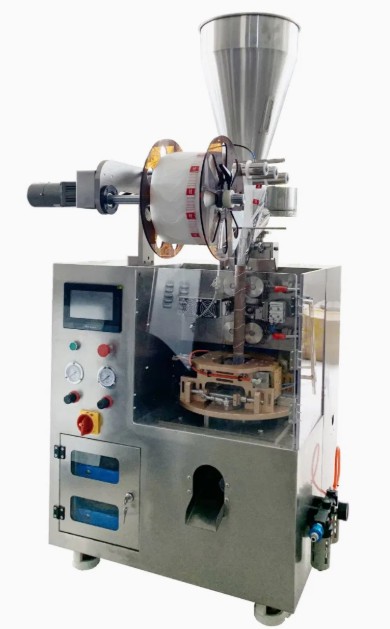

| Application | Cleaning, Detergent, Cosmetics, Drinks, Dairy Products, Hair Care Products, Oil, Tea, Fish, Meat, Snack, Rice, Flour, Seasoning | Automatic Grade | Automatic | Color | Silver |

|---|---|---|---|---|---|

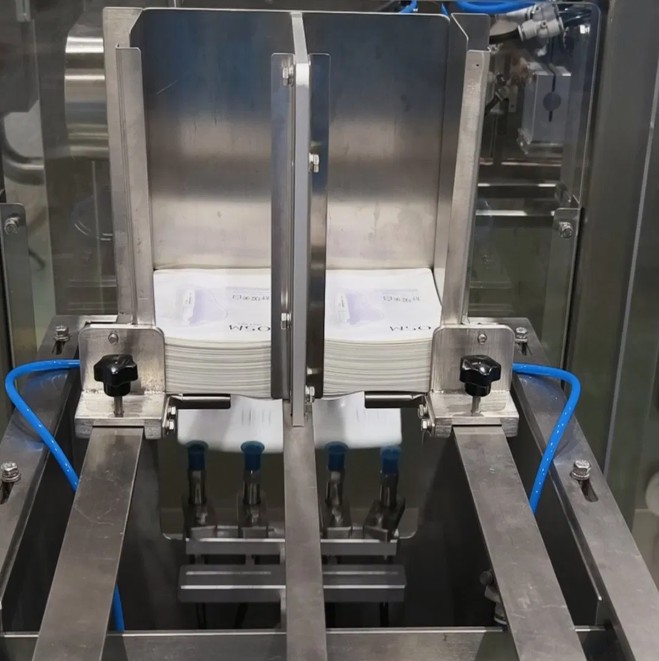

| Driven Type | Electric | Forming Function | Filling, Seal | Forming Species | Filling and Sealing |

| Material | 304 Stainless Steel | Material Type | Powder/Liquid/Granule/Paste | Model NO. | APHPM-210-DUPLEX |

| Origin | China | PLC | Panasonic | Packaging | Bag |

| Packaging Material | Plastic | Production Capacity | 2000 Sets/Year | Specification | L271.0*W174.1*H150.0cm |

| Touch Screen | Inovance | Transport Package | Wooden Case | Type | Filling and Sealing Machine |

Product Description

In today’s fast-paced manufacturing world, precision and speed are paramount. Liquid filling machines stand at the heart of industries that require the accurate and efficient packaging of liquid products. Whether it's in food and beverage production, pharmaceuticals, cosmetics, or chemicals, these machines play a pivotal role in ensuring the safe and precise delivery of products to the market.

What Are Liquid Filling Machines?

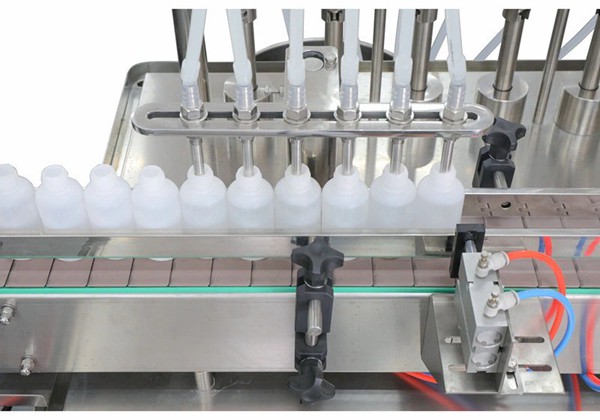

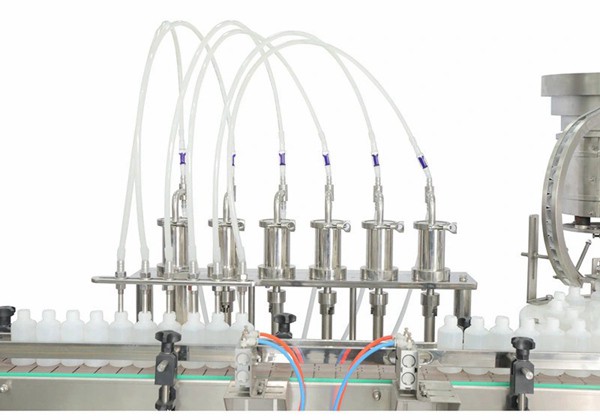

Liquid filling machines are automated systems designed to fill containers with liquid products at a high speed while maintaining accuracy and consistency. These machines are equipped to handle a variety of liquids from thin fluids like water and beverages to thicker substances like oils, creams, and gels. The technology behind these machines ensures that each container is filled to the required volume with minimal waste or spillage.

Core Features of Liquid Filling Machines

1. Versatility: Liquid filling machines are designed to handle a wide range of liquid types, including volatile liquids, thick pastes, and foamy substances. This versatility makes them suitable for use in diverse industries such as food processing, cosmetics, pharmaceuticals, and chemicals.

2. Accurate and Consistent Fill Volume: One of the primary features of a liquid filling machine is its ability to deliver precise fill volumes. These machines often use advanced sensors or flow meters to monitor the exact amount of liquid dispensed into each container, ensuring that every product is packaged with consistency and accuracy.

3. Speed and Efficiency: Liquid filling machines are built to process high volumes of liquid products in a short amount of time. With speeds ranging from a few containers per minute to hundreds depending on the machine’s configuration, these systems ensure that production lines remain fast and efficient without sacrificing quality.

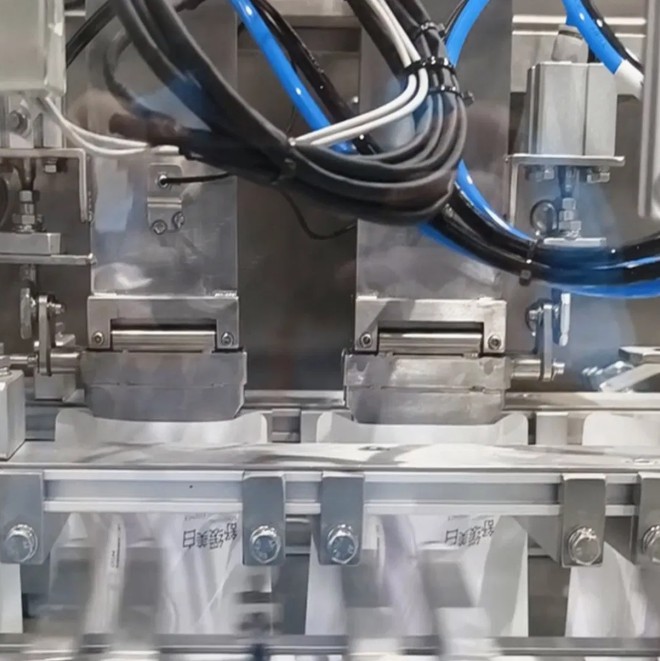

4. Automation and Integration: Modern liquid filling machines are highly automated, reducing the need for manual labor and minimizing the risk of human error. They can be easily integrated into existing production lines and are often paired with other machinery such as capping and labeling machines to streamline the entire packaging process.

5. Easy Cleaning and Maintenance: Hygiene is crucial in industries like food and pharmaceuticals. Many liquid filling machines are designed with features that allow for easy disassembly and cleaning. This is particularly important for maintaining strict sanitation standards and avoiding cross-contamination between batches.

Key Advantages of Liquid Filling Machines

1. Increased Production Capacity: By automating the liquid filling process, manufacturers can significantly increase their output, which is crucial for meeting growing demand. These machines can operate continuously for long hours with minimal downtime, improving overall productivity.

2. Reduction of Operational Costs: The automation provided by liquid filling machines reduces labor costs and improves efficiency. Additionally, their precise dispensing mechanism helps minimize waste, leading to cost savings in materials.

3. Enhanced Product Quality and Consistency: The precision and consistency of liquid filling machines ensure that each product meets the necessary quality standards. This is vital for maintaining customer satisfaction and complying with regulatory requirements.

4. Scalability: Whether you are a small business or a large enterprise, liquid filling machines can be customized to suit your production needs. From low-volume operations to high-output facilities, there are machines available to meet every scale of production.

Applications of Liquid Filling Machines

Liquid filling machines are indispensable in a variety of industries. In the food and beverage sector, they are used to fill bottles with drinks, sauces, and oils. In the pharmaceutical industry, they play a critical role in filling bottles or vials with medicines and health supplements. Cosmetic companies rely on these machines to package lotions, perfumes, and shampoos. Additionally, the chemical industry uses liquid filling machines to handle products such as detergents and cleaning agents.

In each of these industries, liquid filling machines help meet consumer demand while maintaining high standards of quality and safety. Their versatility, precision, and efficiency make them an essential tool for businesses looking to scale up operations and optimize their packaging processes.

Conclusion

In summary, liquid filling machines are an essential part of modern packaging lines, offering significant benefits in terms of speed, precision, and efficiency. By incorporating these machines into your production process, you can not only enhance your output but also ensure the consistency and quality of your products. Whether you're in food, pharmaceuticals, or chemicals, a liquid filling machine is an investment that can drive productivity and improve the overall efficiency of your manufacturing operations.

Recommended Products

Recently Viewed

Filling Machines: Elevate Your Packaging Process with Smart Automation

Filling Machines: Elevate Your Packaging Process with Smart Automation Filling Machines: Precision, Efficiency, and Versatility

Filling Machines: Precision, Efficiency, and Versatility Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions

Unlock Efficiency with Liquid Filling Machines: The Backbone of Modern Packaging Solutions Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility

Revolutionizing Production with Liquid Filling Machines: Efficiency, Precision, and Versatility Efficient Liquid Filling Machines: Streamlining Your Production Process

Efficient Liquid Filling Machines: Streamlining Your Production Process

Contact Us

Shanghai Leadworld Machinery Technology Co., Ltd.