Welcome!

Efficient Tree Debarkers: The Ultimate Tool for Timber Processing and Forestry Operations

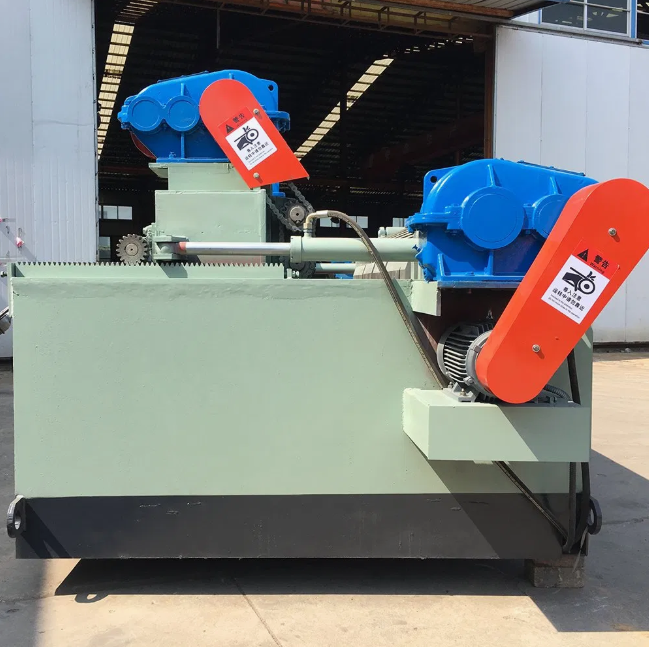

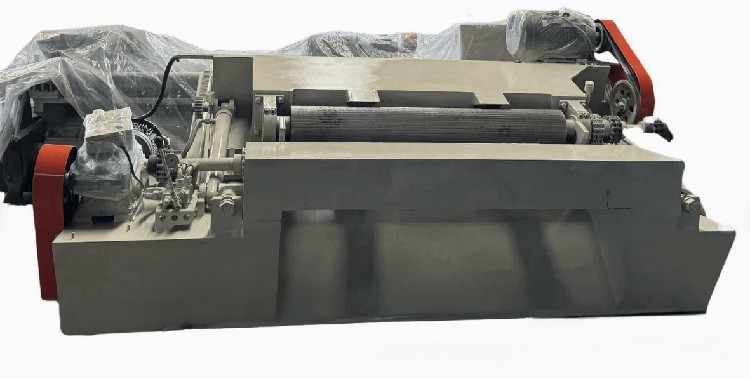

Basic Info

| Automatic | Semi-Automatic | Certification | CE | Customize | Available |

|---|---|---|---|---|---|

| Knife Blade Size | 2900*140*12.7 mm | Model NO. | BWZY-L2900-D550 | Origin | China |

| Package Gross Weight | 6000.000kg | Package Size | 530.00cm * 215.00cm * 110.00cm | Peeling Speed | 45m/Min |

| Production Capacity | 10/ Month | Specification | 5300*2150*1100 mm | Transport Package | Plastic Film |

| Type | Wood Debarker | Wood Log Size | Max. Length 2600 mm | ||

Product Description

In the world of forestry and timber processing, efficiency and precision are paramount. Among the crucial tools used in these industries, tree debarkers stand out as indispensable assets for preparing logs for sawmills, veneer production, and lumber handling. Designed to streamline the debarking process, these machines help boost productivity, reduce waste, and ensure high-quality raw materials for further processing.

What Are Tree Debarkers and How Do They Work?

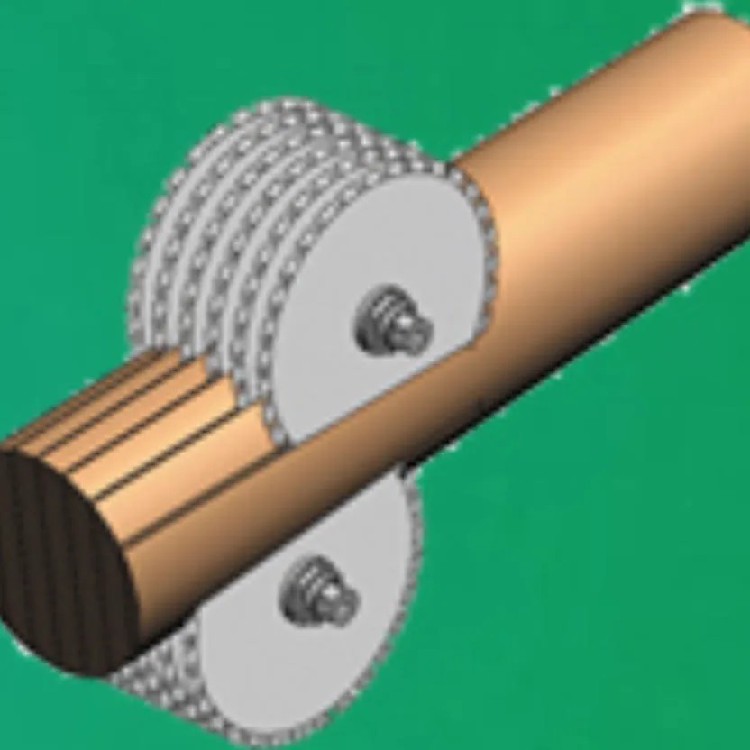

Tree debarkers are specialized machines engineered to remove bark from standing trees or logs quickly and effectively. The process involves different methods, including mechanical bark removal through rotating blades or rubberized wheels that gently peel off bark without damaging the underlying wood. The machine can operate on various sizes and types of logs, making it versatile for commercial forestry, pulp and paper industries, and sawmill applications.

Typically, tree debarkers feature adjustable settings that accommodate different bark thicknesses and log diameters. They are built with durable materials, ensuring long-term operation even in rugged outdoor conditions. The debarking process is designed to be rapid, often capable of processing several logs per minute, reducing labor costs and increasing throughput.

Key Features and Benefits of Tree Debarkers

1. Enhanced Productivity: High-capacity debarking machines significantly accelerate log processing, enabling sawmills and forestry companies to handle larger volumes in less time. The automation and efficiency of modern debarkers mean fewer manual labor hours and quick turnaround times.

2. Superior Debarking Quality: Modern debarkers produce cleaner logs with minimal bark residue, which benefits downstream processing. Well-debarked timber reduces wear and tear on saw blades and enhances the quality of final products.

3. Preservation of Log Integrity: Unlike manual or less precise methods, advanced debarking equipment carefully removes bark without damaging the wood, helping preserve the structural integrity of logs and preventing unnecessary wastage.

4. Versatility and Adaptability: Whether working with small diameter logs or large, heavy timber, adjustable settings and modular designs make debarkers adaptable to diverse operational needs. Many models also offer optional features such as integrated chippers or additional rollers.

5. Cost-Effectiveness and Sustainability: Efficient bark removal reduces raw material waste and minimizes the need for secondary processing. Additionally, energy-efficient models contribute to environmentally friendly operations, lowering overall operational costs.

Primary Applications and Industries

Tree debarkers serve a broad spectrum of industries. Foresters and logging companies utilize them to prepare logs directly from harvest sites. Sawmill operations rely on debarkers to ensure that raw logs meet processing standards. The paper and pulp industry benefits from cleaner raw material, which translates into better pulp quality. Additionally, firewood producers use debarkers to streamline the preparation process, making their products more appealing to customers.

Frequently Asked Questions (Q&A)

Q1: Can tree debarkers handle all tree species?

Most modern debarkers are designed to work efficiently across a variety of tree species, including softwood and hardwood varieties. However, differences in bark thickness and wood density may influence machine settings or require specific model features.

Q2: What size logs can a typical debarking machine process?

Debarkers vary in their capacity, but many are capable of processing logs ranging from 6 inches to over 24 inches in diameter with some heavy-duty models handling larger sizes for industrial applications.

Q3: Are tree debarkers difficult to operate?

No. Most models come with user-friendly controls and require minimal training. Safety features and clear operational guidelines ensure smooth and secure handling by operators.

Q4: How much maintenance do debarking machines need?

Routine maintenance involves checking blades or rollers for wear, lubrication, and inspecting mechanical parts. Proper maintenance schedules help extend the lifespan of the equipment and ensure optimal performance.

Q5: Are there environmentally friendly options for debarking machines?

Yes, many manufacturers offer eco-conscious models that optimize energy use and reduce waste. Additionally, efficient bark removal minimizes secondary processing requirements and raw material waste.

Final Thoughts

Tree debarkers are crucial tools that facilitate faster, cleaner, and more efficient forestry and timber processing. Their versatility, combined with technological advancements, makes them an essential investment for operations seeking high-quality raw materials, streamlined workflows, and improved sustainability. Whether utilized in small-scale forestry or large industrial settings, choosing the right debarking machine can significantly impact productivity and bottom-line success.

Recommended Products

Recently Viewed

Unlocking Sustainable Forest Management with Advanced Forestry Machinery

Unlocking Sustainable Forest Management with Advanced Forestry Machinery Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management

Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Contact Us

Yucheng Runming Machinery Co., Ltd.