Welcome!

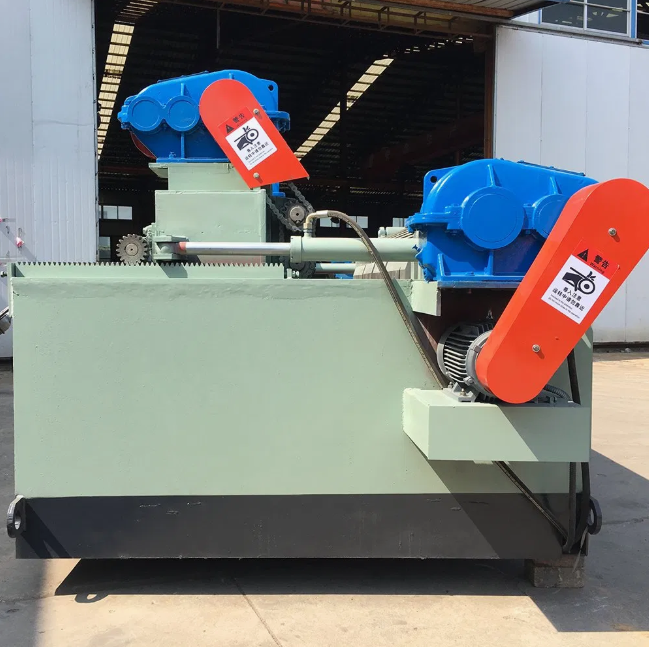

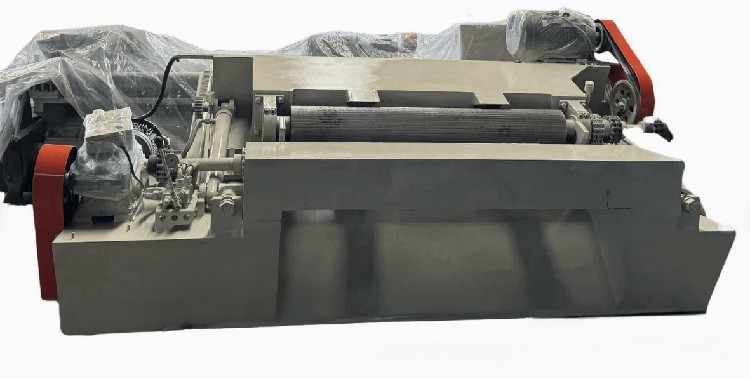

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Basic Info

| After-sales Service | 1 Year | Automatic Grade | Automatic | Blade Diameter | 355mm |

|---|---|---|---|---|---|

| Certification | ISO | Condition | New | Layout | Vertical |

| Origin | Zouping Shandong China | Specification | 3500*1600*1600mm | What Types of Wood Are Available | Wood,Log etc |

Product Description

In the ever-evolving world of woodworking and manufacturing, efficiency, precision, and consistency are paramount. Automated wood cutting machines have emerged as game-changers, transforming how professionals and large-scale workshops handle wood materials. These sophisticated systems are designed to streamline production, reduce waste, and enhance output quality with minimal human intervention. Whether you're crafting custom furniture, producing architectural elements, or managing high-volume timber processing, an automated cutting solution can significantly elevate your operational capabilities. This comprehensive guide delves into the core aspects of these machines, highlighting their features, benefits, and practical applications to help you understand their transformative potential.

Core Features of Automated Wood Cutting Machines

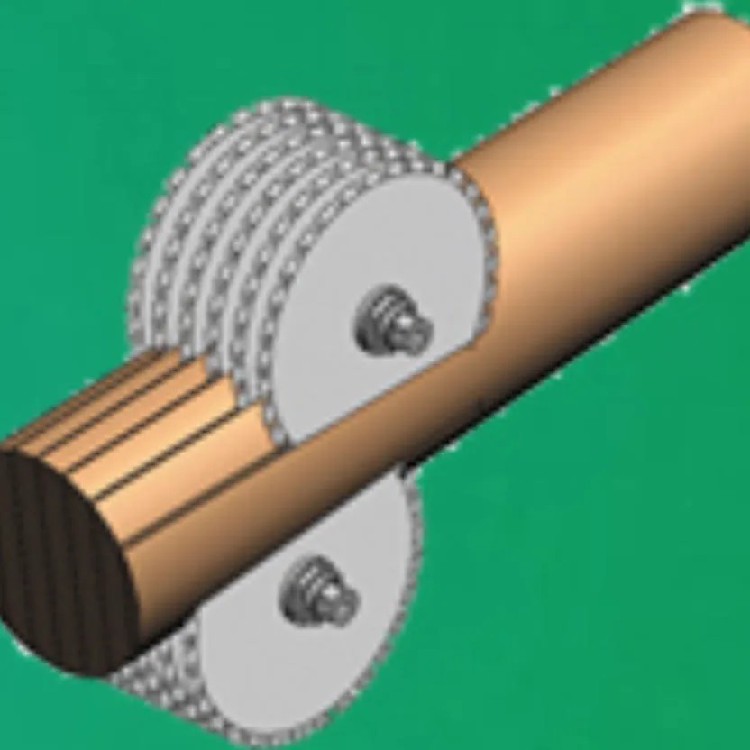

Automated wood cutting machines integrate advanced technology to deliver unparalleled performance. Key features include precision cutting mechanisms powered by high-speed blades or lasers, which are controlled through computer numerical control (CNC) systems. These CNC systems allow for exact replication of designs from digital files, ensuring every cut is consistent and accurate. Many models also come equipped with automated material handling systems, such as conveyors or loading arms, which facilitate continuous operation without manual intervention. Safety features are robust, often including emergency stop buttons, protective enclosures, and sensors that detect anomalies. Additionally, these machines support various cutting styles—like straight, curved, or bevel cuts—and can handle multiple wood types, from softwoods to hardwoods, thanks to adjustable speed and power settings.

Significant Advantages for Modern Workflows

Investing in an automated wood cutting machine offers numerous advantages that directly impact productivity and profitability. Firstly, it dramatically increases production speed, completing tasks in a fraction of the time required by manual methods. This efficiency boost allows businesses to take on more projects and meet tight deadlines effortlessly. Secondly, the precision of these machines minimizes material waste by optimizing cut patterns and reducing errors, leading to cost savings on raw materials. Consistency is another major benefit; every piece produced is identical, which is crucial for large orders requiring uniformity. Labor costs are also reduced as one operator can manage multiple machines, freeing up staff for higher-value tasks. Moreover, enhanced safety mechanisms protect workers from potential hazards associated with manual cutting, creating a safer workplace environment.

Primary Applications and Use Cases

Automated wood cutting machines are versatile tools used across various industries. In furniture manufacturing, they excel at cutting components for chairs, tables, and cabinets with high accuracy. Construction companies utilize them for producing structural elements like beams and trusses, as well as decorative features such as moldings and panels. The packaging industry benefits from these machines for creating custom wooden crates and pallets efficiently. Additionally, they are ideal for custom woodworking shops that specialize in unique, intricate designs like artistic carvings or musical instruments, where precision is critical. Their adaptability makes them suitable for both mass production and bespoke projects, ensuring broad applicability.

Frequently Asked Questions About Automated Wood Cutting Machines

Q: How does an automated wood cutting machine improve accuracy?

A: These machines use CNC technology to follow digital design plans exactly, eliminating human error. Sensors and software continuously monitor and adjust the cutting process, ensuring each cut meets precise specifications.

Q: Can these machines handle different types of wood?

A: Yes, most models are designed to work with various wood species, including softwoods like pine and hardwoods like oak. Adjustable settings allow operators to customize speed, pressure, and blade type based on material density and thickness.

Q: What maintenance is required for optimal performance?

A: Regular maintenance includes blade sharpening or replacement, cleaning of dust and debris, software updates, and periodic calibration of CNC components. Proper upkeep ensures longevity and consistent performance.

Q: Are automated wood cutting machines suitable for small businesses?

A: While traditionally used in large operations, there are compact and affordable models available that cater to small workshops. These offer scalability, allowing businesses to start with basic automation and upgrade as they grow.

Q: How do these systems integrate with existing workflows?

A: They are designed for compatibility with common design software (like CAD programs) and can often be integrated into existing production lines through modular components, making adoption seamless.

Q: What safety features are included?

A: Standard features include emergency stops, protective guarding, automatic shutdown upon detecting obstructions, and dust collection systems to maintain a clean and safe workspace.

Embracing the Future of Woodworking

Automated wood cutting machines represent a significant leap forward in manufacturing technology, offering a blend of precision, efficiency, and versatility that manual methods cannot match. By understanding their features, advantages, and applications, businesses can make informed decisions about integrating this technology into their operations. As the industry continues to advance, these machines will play a pivotal role in shaping the future of woodworking, enabling creators to achieve more with less effort and greater consistency. Explore the possibilities and take your production capabilities to the next level with automation.

Recommended Products

Recently Viewed

Unlocking Sustainable Forest Management with Advanced Forestry Machinery

Unlocking Sustainable Forest Management with Advanced Forestry Machinery Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management

Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Contact Us

Yucheng Runming Machinery Co., Ltd.