Welcome!

The Ultimate Guide to Wood Peeler: Precision, Efficiency, and Versatility in Woodworking

Basic Info

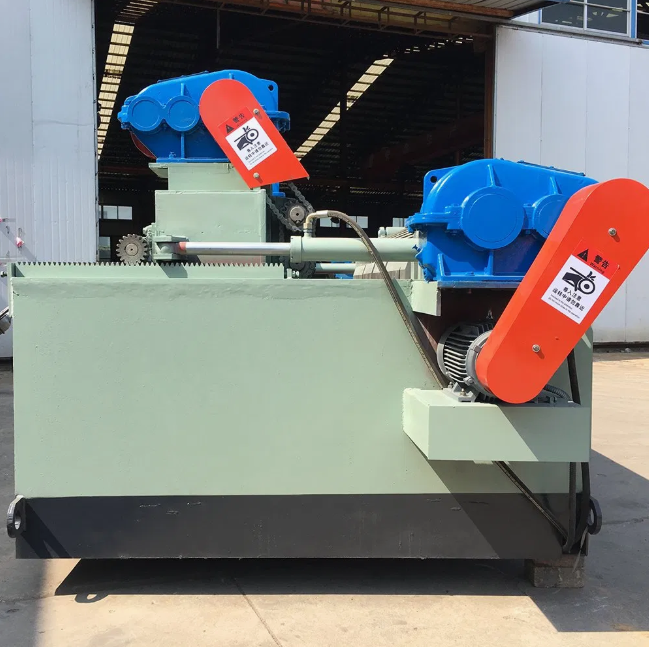

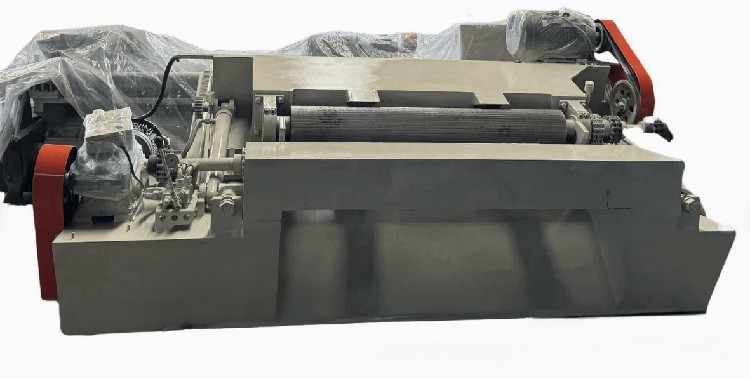

| Capacity | 5-10 Tons Per Hour | Log Diameter | 15-320mm | Model | 6000 |

|---|---|---|---|---|---|

| Model NO. | 6000 | Motor | 37kw | Name | Single Rotor Log Debarker |

| Origin | China | Package Gross Weight | 13000.000kg | Package Size | 800.00cm * 200.00cm * 250.00cm |

| Production Capacity | 200 Sets Per Year | Rotor Length | 6000mm | Warranty | 1 Year |

Product Description

When it comes to woodworking, achieving smooth, uniform surfaces on wooden materials is essential for both aesthetic appeal and functional performance. A wood peeler, also known as a wood planer or wood stripping tool, is an indispensable device designed to efficiently remove layers of wood or peels from logs, planks, or surfaces. Whether you're a professional carpenter, furniture maker, or a woodworking enthusiast, understanding the core features and benefits of a high-quality wood peeler can elevate your projects to the next level.

Understanding the core features of a wood peeler

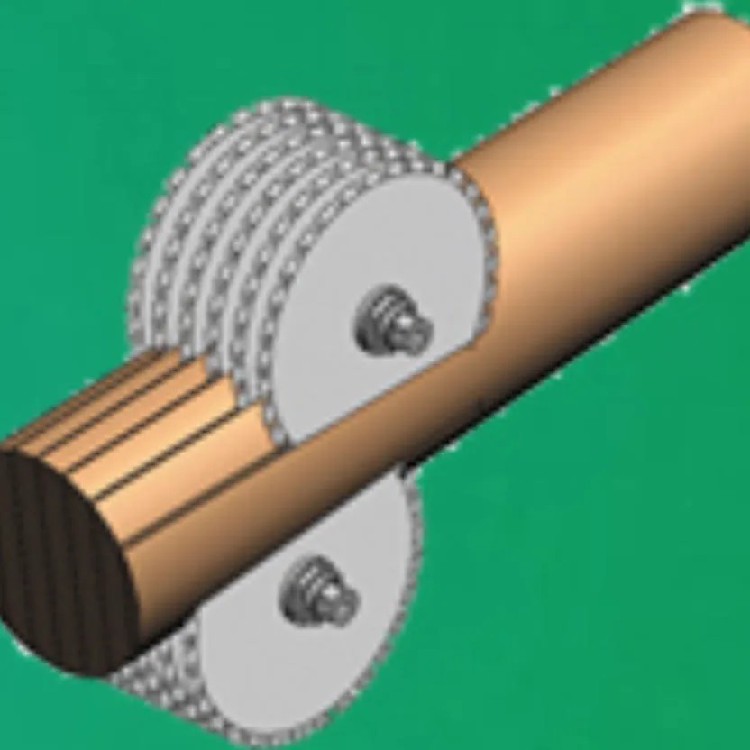

A wood peeler primarily functions to strip or trim wood surfaces, providing clean and precise results with minimal effort. Typically, these tools feature adjustable blades or rollers that can be finely tuned to control the thickness of the peeled layer, ensuring versatility according to the specific task. Many wood peelers come equipped with ergonomic handles that promote safety and reduce fatigue during prolonged use. Modern designs often include safety guards and durable materials like stainless steel blades, guaranteeing longevity and consistent performance.

This tool is versatile enough to handle a variety of applications. It can be used for preparing timber before further processing, removing bark or rough outer layers from logs, shaping wood for furniture, or even crafting decorative wooden pieces. Its ability to produce smooth and peeled surfaces makes it invaluable in wood restoration projects and custom woodworking.

Key advantages of using a wood peeler

One of the most apparent benefits of a wood peeler is its efficiency. Compared to manual chiseling or sanding, a well-designed peeler allows for rapid material removal, saving time and effort. Its adjustable mechanism ensures precise control over the thickness of the peel, granting users mastery over the final appearance of their wood piece.

Additionally, a wood peeler enhances safety in woodworking. With proper use, it minimizes splinters and reduces the chance of accidental cuts that can occur with traditional hand tools. The ergonomic design also promotes comfortable operation, reducing strain during long sessions-an advantage particularly valuable for professional workshops or home carpentry projects.

Moreover, investing in a durable and high-quality wood peeler tends to be cost-effective over time. Its long-lasting blades and sturdy construction ensure consistent results across multiple uses, making it a reliable tool in your workshop arsenal.

Applications and ideal use cases

Wood peelers are highly adaptable and suitable for a broad range of projects. They are ideal for log and timber preparation in furniture manufacturing especially when preparing planks or slabs for further processing. Artists and craftspersons utilize wood peelers to produce decorative accents, carvings, or custom wooden fixtures. They are also essential in the veneer industry, where precise peeling results are critical for high-quality veneer sheets.

In restoration projects, a wood peeler can efficiently remove the damaged outer layers of wood, revealing fresh surfaces underneath. It is equally beneficial for hobbyists who enjoy crafting wooden sculptures or DIY projects, offering a combination of precision and ease of use that guarantees professional-looking outcomes.

Frequently Asked Questions about Wood Peelers

Q1: How does a wood peeler differ from a planer or sander?

A: While a planer or sander is used mainly for smoothing and finishing surfaces, a wood peeler is designed specifically to strip layers off logs or rough surfaces quickly. It primarily removes outer bark, rough layers, or excess material, preparing the wood for further shaping or finishing.

Q2: Can a wood peeler be used on all types of wood?

A: Most wood peelers are suitable for a wide range of wood species, including hardwoods and softwoods. However, extremely dense or exotic woods might require more robust blades or specific settings for optimal results.

Q3: Is it difficult to operate a wood peeler?

A: With a bit of practice, most users find wood peelers easy to master. Adjustable settings and ergonomic handles enhance control, making the process straightforward even for beginners.

Q4: How often do the blades need replacing?

A: Blade lifespan varies based on usage and wood type but typically lasts for several projects. Regular inspection and sharpening extend its life, and replacements are usually simple to install.

Q5: What safety precautions should I consider when using a wood peeler?

A: Always wear safety goggles and gloves to protect against splinters or blade contact. Ensure that your workspace is well-lit and stable, and follow the manufacturer’s instructions for safe operation.

Final thoughts

Investing in a quality wood peeler offers versatility, efficiency, and cleaner results in any woodworking endeavor. Its ability to tackle diverse tasks from bark removal to precise peeling makes it an essential tool for both professionals and passionate hobbyists. By understanding its features and proper usage, you can unlock new levels of craftsmanship and produce stunning wooden pieces every time. No matter your project scope, a reliable wood peeler can streamline your workflow and elevate the quality of your work.

Recommended Products

Recently Viewed

Unlocking Sustainable Forest Management with Advanced Forestry Machinery

Unlocking Sustainable Forest Management with Advanced Forestry Machinery Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management

Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Contact Us

Yucheng Runming Machinery Co., Ltd.