Welcome!

Fully automatic CNC bending machines - hydraulic metal bending machines

Basic Info

| Automation | Automatic | Bending Force | 110/130/170/220/ Tons(Customizable) | Bending Length | 4000mm/(Customizable) |

|---|---|---|---|---|---|

| Certification | RoHS, ISO 9001:2000, ISO 9001:2008, CE | Condition | New | HS | 84622990 |

| Laser Protection | DSP(Optional) | Main Motor | Siemens | Package | Steel Pallet Packaged |

| Product Name | CNC Press Brake Machine | Production Capacity | 50000 | Production Capacitys | 80 Units/Month |

| Specifications | CE Standard | Type | Press Brake | Usage | Copper Aluminum, Alloy, Carbon Steel, Stainless S |

Product Description

CNC bending machines are advanced industrial tools designed to shape metal sheets, tubes, and profiles into precise geometries with speed, accuracy, and repeatability. These machines have become indispensable in industries ranging from automotive and aerospace to construction and consumer electronics, enabling manufacturers to produce complex components efficiently. This article delves into the functionality, types, benefits, and applications of CNC bending machines, highlighting their transformative role in modern manufacturing.

What is a CNC Bending Machine?

A CNC bending machine automates the process of deforming metal workpieces using programmed instructions. Unlike traditional manual bending which relies heavily on operator skill, CNC machines leverage computerized controls to execute bends with exact angles, radii, and dimensions. Depending on the application, these machines can handle various materials, including steel, aluminum, copper, and even high-strength alloys.

Types of CNC Bending Machines

CNC Press Brakes:

The most common type-press brakes use a punch and die system to bend sheet metal. Hydraulic or electric drives apply force to create precise V-shaped, U-shaped, or custom bends.

Tube and Pipe Bending Machines:

Specialized for cylindrical materials, these machines rotate and bend tubes/pipes using mandrels to prevent collapsing. They are critical in automotive exhaust systems and hydraulic tubing.

Roll Bending Machines:

Equipped with rollers, these machines gradually curve metal sheets or profiles into arcs or cylinders, ideal for producing large-radius bends.

Panel Benders:

Designed for high-speed bending of thin sheets, panel benders automate multiple bends in sequence used for enclosures or casings often.

Key Components and Operation

CNC Controller: Act as the machine’s brain, interpreting CAD/CAM files to coordinate movements and force application.

Bending Tools: Customizable punches, dies, and mandrels tailored to material thickness and bend requirements.

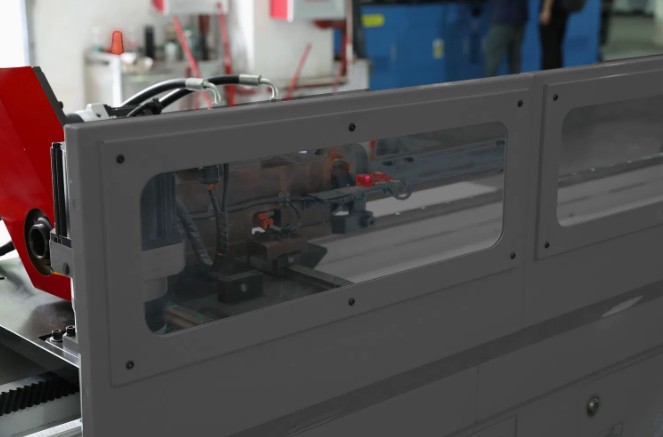

Back Gauge System: Accurately position the workpiece using servo-driven axes (X, Y, Z, R).

Drive Mechanism: Hydraulic systems offer high force for thick materials, while electric servo systems provide energy efficiency and precision for thin sheets.

Workflow:

The operator uploads a 3D design file to the CNC controller.

The machine automatically selects tools and adjusts parameters (e.g., bend angle, depth).

The workpiece is clamped, and the bending tool applies force to achieve the desired shape.

Real-time sensors monitor accuracy, making micro-adjustments to ensure consistency.

Advantages of CNC Bending Machines

Ultra-High Precision: Achieve tolerances within ±0.1° for angles and ±0.05 mm for positioning.

Speed and Efficiency: Reduce production time through automated tool changes and minimal setup.

Versatility: Accommodate diverse materials, thicknesses (up to 30 mm), and complex geometries.

Repeatability: Ensure identical results across mass production runs.

Cost-Effectiveness: Minimize material waste and labor costs while maximizing output quality.

Applications Across Industries

CNC bending machines manufacture critical components such as:

Automotive: Chassis parts, brackets, and exhaust systems.

Aerospace: Structural frames and lightweight alloy components.

Construction: Steel beams, HVAC ducts, and architectural façades.

Electronics: Enclosures, heat sinks, and connector housings.

Energy: Solar panel frames and pipeline fittings.

About Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd. is a comprehensive enterprise integrating enterprise management, market sales, and production. Its sales and service outlets are all over China and all over the world. Company metal sheet processing machinery: Hydraulic shear plate machine, hydraulic bending machine, press machine (press), hydraulic angle iron roll circle machine, three roll plate machine, electric shear plate machine, foot scissors board machine, shearing machine bending machine accessories, cutting plate machine blade, bending machine die and so on.

Recommended Products

Recently Viewed

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology CNC Bending Machines: Precision and Efficiency in Metal Fabrication

CNC Bending Machines: Precision and Efficiency in Metal Fabrication CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing

CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing Precision Unlocked: Your Complete Guide to CNC Bending Machines

Precision Unlocked: Your Complete Guide to CNC Bending Machines Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Contact Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd.