Welcome!

Precision Redefined: CNC Bending Machines for Modern Metal Fabrication

Basic Info

| Applicable Material | S. S., M. S., Copper, Aluminium, Alloy, Galvanized | Applicable Shape | Oval, Round, Square, Rectangular | Automation | Automatic |

|---|---|---|---|---|---|

| Axis Number | 3 | Bending Angle ° | ±0.1° | Dimensions mm | 5.00*1.50*1.50m |

| Feeding length | ±0.1mm | Maximum Bending Angle ° | 190° | Maximum Bending Capacity (CLR1.5D) | Ø63.5×2.0t |

| Model NO. | AL-65CNCx3A-1S | Origin | China | Specification | 5.00*1.40*1.50m |

| Tilting Angle ° | ±0.1° | Transport Package | Wooden Packaging | Warranty | 1 Year |

| Weight kg | 3800kg | ||||

Product Description

Product Introduction

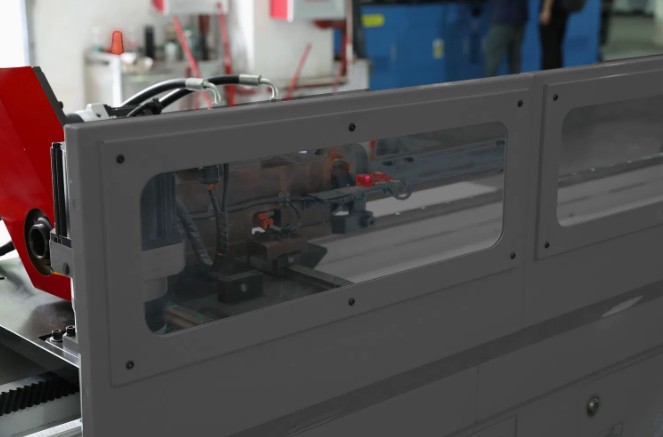

CNC (Computer Numerical Control) bending machines are advanced industrial equipment designed to automate and streamline the precision bending of sheet metal, tubes, and profiles. These machines utilize cutting-edge CNC technology to deliver high-accuracy and repeatable results for complex forming applications across industries such as automotive, aerospace, construction, electronics, and HVAC.

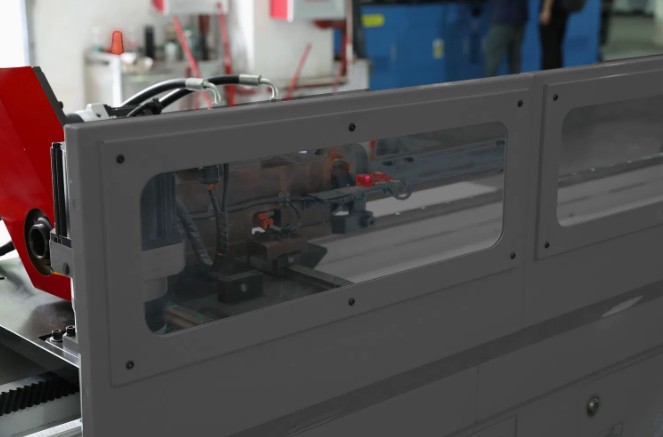

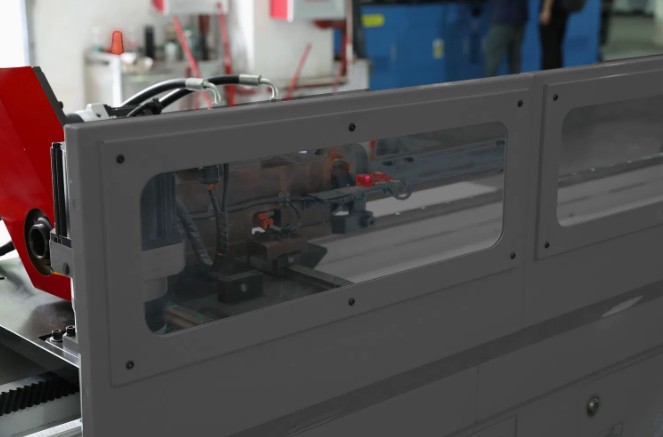

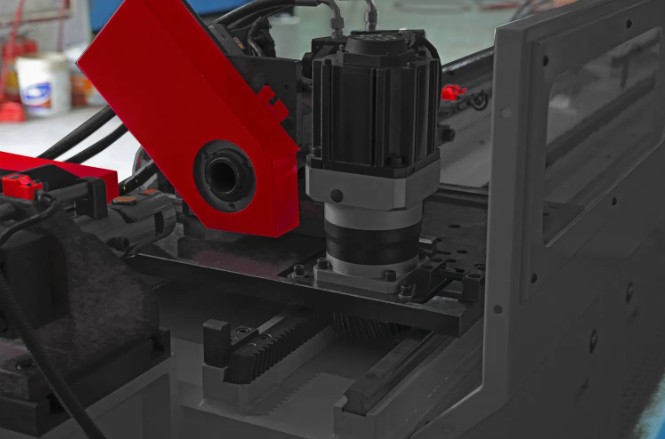

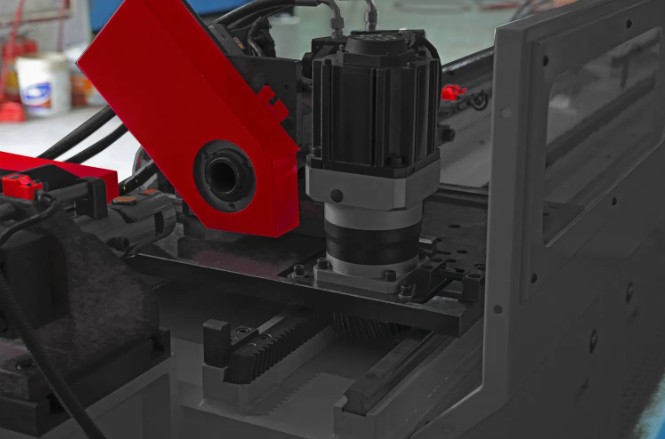

Equipped with hydraulic or electric drive systems, CNC bending machines feature programmable controls that enable operators to input bending parameters, angles, and sequences via an intuitive interface. Key components include a rigid frame, adjustable clamping tools, precision dies, and a backgauge system for material positioning. The machines are compatible with a wide range of materials, including stainless steel, aluminum, copper, and mild steel, making them versatile for diverse fabrication needs.

Modern CNC bending machines integrate smart features such as automatic angle correction, real-time force monitoring, and multi-axis synchronization. They support 2D/3D CAD file import, allowing seamless translation of digital designs into physical parts. Advanced models may also incorporate AI-driven optimization algorithms to minimize material waste and maximize production efficiency.

Product Advantages

1. High Precision & Repeatability

CNC bending machines eliminate human error by executing programmed instructions with micron-level accuracy. Consistent results are achieved even for high-volume production runs, ensuring uniformity across batches.

2. Enhanced Productivity

Automated workflows reduce setup times and manual intervention. Features like rapid tool changes, dynamic backgauge adjustments, and batch processing enable faster cycle times, boosting throughput by up to 50% compared to manual bending.

3. Flexibility for Complex Geometries

Capable of creating intricate bends, curves, and multi-angle forms, these machines handle designs, while traditional methods cannot make it. Operators can easily switch between jobs by recalling saved programs, ideal for custom or small-batch production.

4. Energy Efficiency & Sustainability

Electric-driven models consume less power than hydraulic systems, lowering operational costs and environmental impact. Precision control also reduces material scrap rates, supporting sustainable manufacturing practices.

5. User-Friendly Operation

Intuitive touchscreen interfaces and simulation software simplify programming even for complex parts. Error-detection systems and self-diagnostic tools minimize downtime, while remote monitoring enables proactive maintenance.

6. Durability & Safety

Built with robust materials and overload protection mechanisms, CNC bending machines ensure long-term reliability. Safety features like laser guards, emergency stops, and light curtains protect operators during high-force operations.

7. Cost-Effective ROI

Reduced labor dependency, minimized rework, and faster turnaround times translate to significant cost savings over time. The machines’ adaptability future-proofs production lines, accommodating evolving industry demands.

About Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd. is a leading Chinese enterprise specializing in the design, production, and distribution of high-quality heavy industrial machinery and equipment. Established with a commitment to innovation and reliability, the company serves global clients across sectors such as mining, construction, energy, and material handling, offering customized solutions including crushers, grinding mills, conveyors, and heavy-duty components. Leveraging advanced manufacturing technologies, a skilled engineering team, and strict adherence to international quality standards such as ISO certification, Guoao Heavy Industry ensures durable and efficient machinery tailored to meet diverse operational demands. With a customer-centric approach, it provides comprehensive technical support and after-sales services, reinforcing its reputation as a trusted partner in driving industrial productivity worldwide.

Recommended Products

Recently Viewed

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology CNC Bending Machines: Precision and Efficiency in Metal Fabrication

CNC Bending Machines: Precision and Efficiency in Metal Fabrication CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing

CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing Precision Unlocked: Your Complete Guide to CNC Bending Machines

Precision Unlocked: Your Complete Guide to CNC Bending Machines Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Contact Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd.