Welcome!

CNC Bending Machines: Precision and Efficiency in Metal Fabrication

Basic Info

| Applicable Material | Stainless Steel | Applicable Shape | Square | Applicable Shapes | Ound, Square, Oval, Rectangular |

|---|---|---|---|---|---|

| Automation | Automatic | Certification | ISO 9001:2000, CE | Model NO. | HSB-75CNC |

| Origin | China | Package Gross Weight | 1000.000kg | Package Size | 200.00cm * 150.00cm * 180.00cm |

| Pipe Material | Carbon Steel Stainless Steel Metal Square | Product | Hydraulic Pipe Bending Machine, CNC Pipe Bending M | Specification | HSB-75CNC |

| Transport Package | Wooden Box | Warranty | 1 Year | ||

Product Description

Product Overview

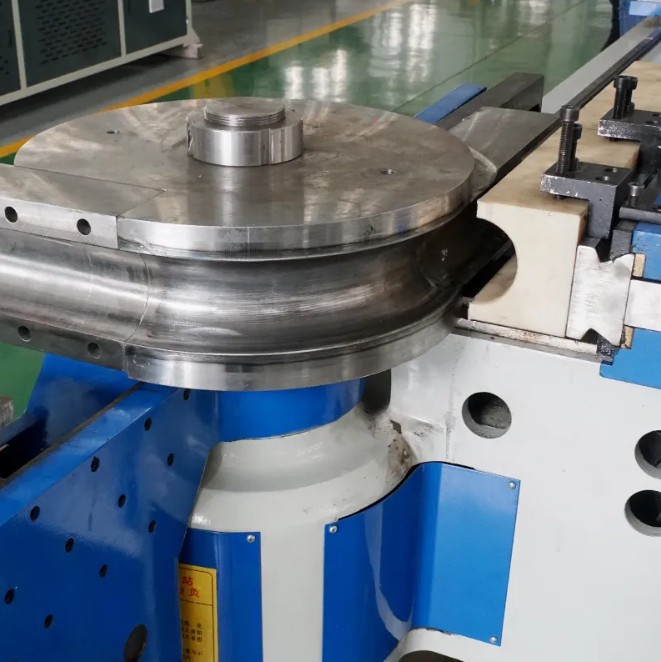

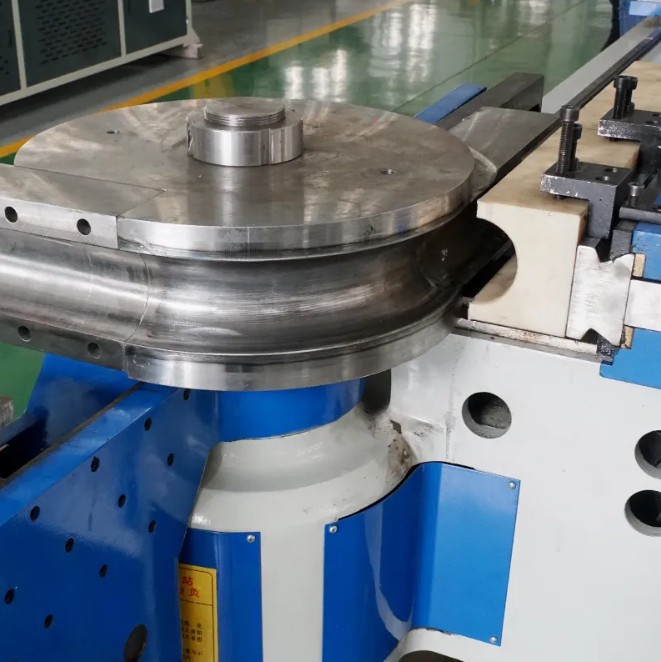

CNC Bending Machines are advanced industrial equipment designed to automate and streamline the metal forming process. Utilizing Computer Numerical Control (CNC) technology, these machines deliver exceptional accuracy and repeatability for bending sheet metal, tubes, and profiles into complex geometries. Ideal for industries such as automotive, aerospace, construction, and electronics, CNC Bending Machines combine robust mechanical design with intelligent software to optimize production workflows.

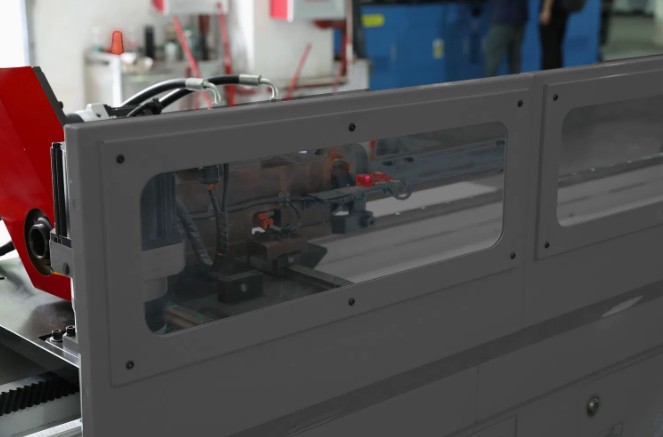

Equipped with multi-axis control systems, these machines precisely manipulate materials using hydraulic or electric actuation, ensuring consistent results across high-volume production runs. The integration of user-friendly interfaces allows operators to program bending sequences, adjust parameters, and monitor performance in real time, minimizing manual intervention and human error.

Key Features

1. High-Precision Backgauge System: Ensure accurate material positioning for repeatable bends even for intricate designs.

2. Adaptive Tooling Options: Compatible with a wide range of dies and punches to accommodate diverse material types and thicknesses.

3. Dynamic Angle Correction: Automatically compensate for springback to maintain tight tolerances.

4. Energy-Efficient Operation: Hydraulic models feature optimized power consumption, while electric models offer silent and low-energy performance.

5. Safety Mechanisms: Built-in sensors, emergency stops, and protective barriers prioritize operator safety.

Product Advantages

1. Superior Productivity

- CNC automation reduces setup times and accelerates cycle speeds, enabling faster order fulfillment.

- Batch processing capabilities allow uninterrupted production of multiple parts with minimal downtime.

2. Unmatched Precision

- Advanced CNC algorithms ensure bending angles and dimensions adhere to exact specifications, reducing scrap rates.

- Ideal for high-tolerance applications in industries like aerospace and medical device manufacturing.

3. Versatility

- Handle materials ranging from thin aluminum sheets to thick stainless steel plates.

- Support custom tooling configurations for unique part geometries.

4. Cost-Effectiveness

- Lower labor costs by reducing reliance on skilled operators for repetitive tasks.

- Extended tool lifespan due to optimized force distribution and wear reduction.

5. Future-Ready Design

- Compatible with Industry 4.0 ecosystems for seamless integration into smart factories.

- Software updates and modular components ensure adaptability to evolving production needs.

6. User-Centric Operation

- Intuitive touchscreen interfaces simplify programming even for complex bends.

- Offline simulation tools allow operators to test and refine bending sequences virtually.

Applications

CNC Bending Machines are indispensable for creating components such as enclosures, brackets, chassis, HVAC ducts, and structural frameworks. Their ability to handle both prototyping and mass production makes them a cornerstone of modern metal fabrication.

Who We Are?

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd. is a leading Chinese enterprise specializing in the design, production, and distribution of high-quality heavy industrial machinery and equipment. Established with a commitment to innovation and reliability, the company serves global clients across sectors such as mining, construction, energy, and material handling, offering customized solutions including crushers, grinding mills, conveyors, and heavy-duty components. Leveraging advanced manufacturing technologies, a skilled engineering team, and strict adherence to international quality standards such as ISO certification, Guoao Heavy Industry ensures durable and efficient machinery tailored to meet diverse operational demands. With a customer-centric approach, it provides comprehensive technical support and after-sales services, reinforcing its reputation as a trusted partner in driving industrial productivity worldwide.

Conclusion

CNC Bending Machines revolutionize metalworking by merging cutting-edge automation with unmatched precision. By enhancing efficiency, reducing waste, and supporting diverse applications, they empower manufacturers to meet today’s demanding quality standards while preparing for tomorrow’s challenges. Invest in CNC bending technology to elevate your production capabilities and stay ahead in a competitive global market.

Recommended Products

Recently Viewed

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology CNC Bending Machines: Precision and Efficiency in Metal Fabrication

CNC Bending Machines: Precision and Efficiency in Metal Fabrication CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing

CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing Precision Unlocked: Your Complete Guide to CNC Bending Machines

Precision Unlocked: Your Complete Guide to CNC Bending Machines Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Contact Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd.