Welcome!

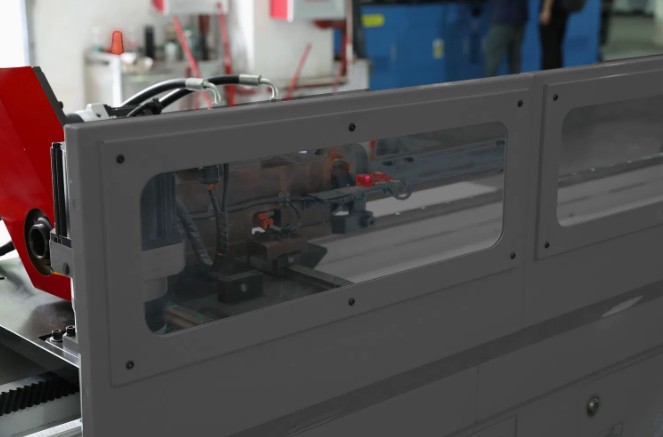

High Precision Mini Press Brake Machine for Sale

Basic Info

| Automation | Automatic | Certification | CE | Control System | CT8, P40, Da66t, CT12 |

|---|---|---|---|---|---|

| HS Code | 8462230000 | Hydraulic System | X Y Axis Hydraulic CNC Press Brake Machine | Keyword | CNC Bending Machine |

| Machine Type | Machine Type | Motor Band | Siemens Motor | Origin | China |

| Product Name | CNC Press Brake Machine | Specification | Please refer to the details page | Suitable for | Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel |

| Throat Depth | 400mm | Transport Package | CNC Bending Machine Wooden Case and Plastic Seal | Type | Press Brake |

| Voltage | According to Customer | Worktable Length | 3200mm | ||

Product Description

In today’s fast-paced manufacturing world, efficiency and flexibility are paramount for small workshops, hobbyists, and businesses tackling tight spaces or custom projects especially. Enter the Mini Press Brake, a compact yet robust solution designed to deliver professional-grade metal bending performance in a fraction of the footprint of traditional industrial machines. Whether you’re crafting intricate prototypes, custom brackets, or decorative metalwork, this innovative tool redefines what’s possible in small-scale fabrication.

Why Choose a Mini Press Brake?

Space-Saving Design

Perfect for workshops with limited space, the mini press brake boasts a streamlined footprint without compromising power. Its portable size allows easy integration into garages, maker spaces, or on-site job locations.

Cost-Effective Performance

Avoid the hefty price tag of full-sized industrial machines. Mini press brakes offer an affordable entry point for startups, artisans, and small businesses, delivering high ROI through reduced overhead and energy consumption.

User-Friendly Operation

Designed for simplicity, many models feature manual or semi-automatic controls, making them accessible even to beginners. Advanced options include CNC compatibility for programmable precision.

Versatility in Metalworking

Bend sheet metal, aluminum, copper, or stainless steel with thicknesses ranging from 0.5 mm to 6 mm (depending on the model). Create precise angles, U-shapes, or complex geometries for applications from electronics enclosures to automotive parts.

Quick Setup and Tool Changes

Swap punches and dies effortlessly to adapt to different projects. Ideal for low-to-medium volume production or one-off custom jobs.

Key Features

Compact Frame: Durable construction with a focus on stability and portability.

Adjustable Stroke and Pressure: Tailor bending force to match material thickness and hardness.

Precision Accuracy: Achieve bend angles within ±0.5° for professional results.

Safety First: Equipped with emergency stops, finger guards, and overload protection.

Optional CNC Integration: Upgrade to automated controls for repeatability in batch production.

About Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd. is a comprehensive enterprise integrating enterprise management, market sales, and production. Its sales and service outlets are all over China and all over the world. Company metal sheet processing machinery: Hydraulic shear plate machine, hydraulic bending machine, press machine (press), hydraulic angle iron roll circle machine, three roll plate machine, electric shear plate machine, foot scissors board machine, shearing machine bending machine accessories, cutting plate machine blade, bending machine die and so on.

Recommended Products

Recently Viewed

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology

CNC Bending Machines: Transforming Metal Fabrication with Smart Technology CNC Bending Machines: Precision and Efficiency in Metal Fabrication

CNC Bending Machines: Precision and Efficiency in Metal Fabrication CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing

CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing Precision Unlocked: Your Complete Guide to CNC Bending Machines

Precision Unlocked: Your Complete Guide to CNC Bending Machines Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Precision Engineered: Unlock New Potential with Advanced CNC Bending Machines

Contact Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd.