Welcome!

Guangdong Shunde Jiaheda Cleaning Equipment Co., L

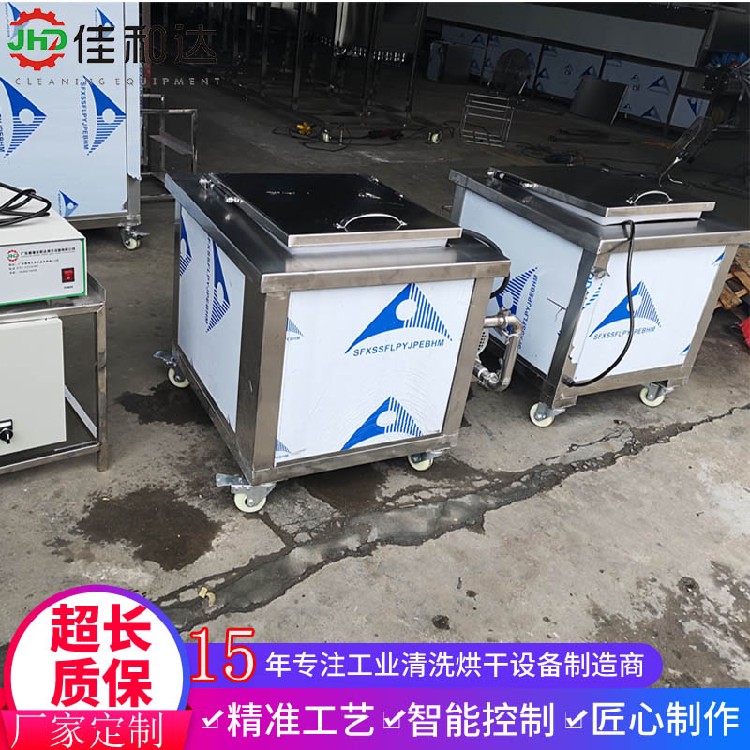

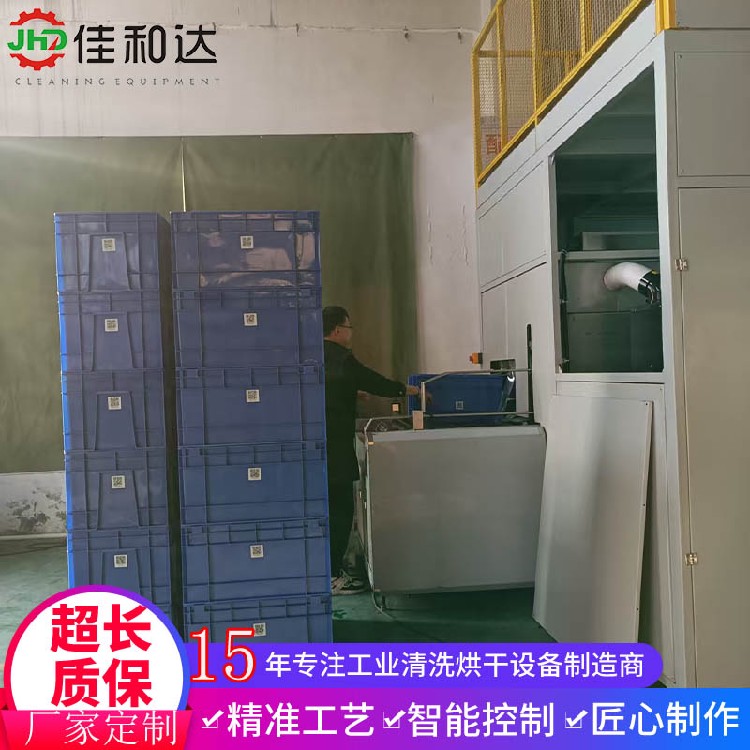

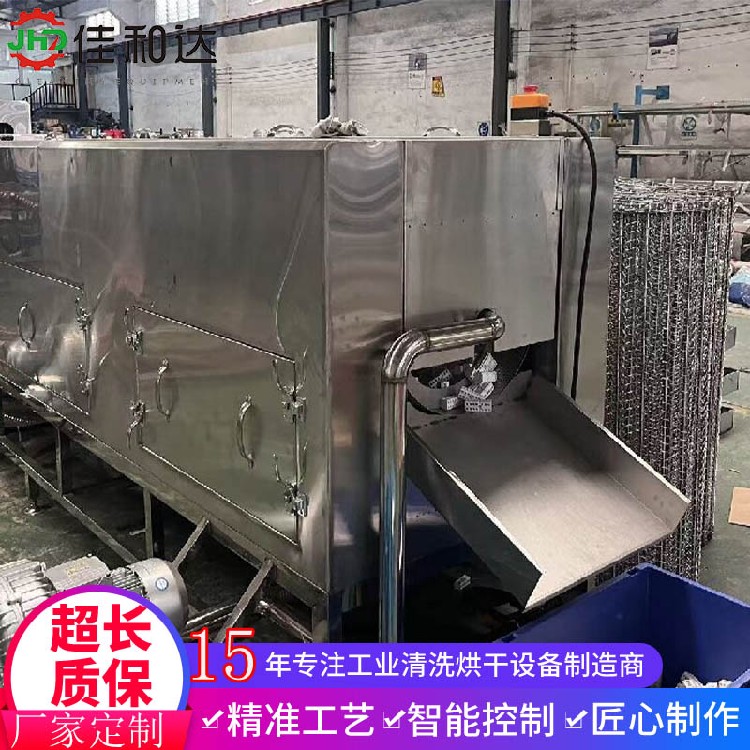

Main products: Ultrasonic cleaning machine , spray cleaning machine, high-temperature drying line, oil removal cleaning line, hanging cleaning and drying line, gantry automatic cleaning line, wax removal cleaning and drying line, box washing machine, high-pressure washing machine, flat brush cleaning machine, tunnel drying oven, natural gas cleaning and drying equipment

Terminal block cleaning dryer

Product Description

Product Overview: Redefining Industrial Standards for Cleaning and Drying

In the fields of high-end electrical manufacturing, automotive wire harnesses, precision instruments and new energy, the cleanliness and absolute dryness of terminal blocks are the lifelines to ensure the long-term stable operation of products. A small amount of grease, flux flux residue, dust or moisture may trigger an arc when power is turned on, resulting in increased resistance, unstable signal transmission, and even catastrophic short-circuit faults in harsh environments. The traditional manual cleaning and natural drying methods are not only inefficient and expensive, but also unable to ensure the consistency and stability of quality, which has become a bottleneck that restricts enterprises from improving quality and efficiency.

For this reason, we have made every effort to create this fully automatic terminal block cleaning and drying all-in-one machine. It deeply integrates mechanical engineering, fluid dynamics and precise temperature control technology to build a seamless and automated "cleaning-dehydration-drying" closed-loop production line. This equipment aims to completely liberate the labor force, eliminate the quality fluctuations caused by human intervention, ensure that every terminal from the production line reaches impeccable cleanliness and dryness, and build the most solid fortress for the quality of your products.

---

Detailed explanation of the core process: the perfect concert of the four precision modules

The first stop: intelligent loading and smooth conveying

· Module Name: Adjustable Speed Belt Conveyor System

· Process description: The terminal blocks processed in the front process (such as crimping and welding) are placed on the feed belt line of the equipment in batches by the operator. This precisely calibrated belt wire is made of food-grade anti-static material, which runs smoothly, is low in noise, and will not cause any scratches on the terminal surface.

· Technical highlights: The conveying speed can be steplessly adjusted according to the production beat to achieve perfect synchronization with the front and rear processes. The built-in guidance device ensures that the workpiece will not be offset or accumulated during transmission, laying the foundation for subsequent precision processing.

The second stop: three-dimensional surround high-efficiency spray cleaning

· Module name: multi-stage high-pressure sprinkler cleaning cabin

· Process description: When the terminal block enters the fully enclosed spray cleaning cabin at a uniform speed with the belt wire, it will undergo a thorough "purification journey". Through a corrosion-resistant stainless steel pump, the system sprays the filtered special cleaning agent (water-based or solvent-based according to the type of pollutant) from multiple dimensions - including top, side and bottom - to the surface of the workpiece at a specific pressure and angle.

· Technical highlights:

· Three-dimensional sprinkler system: Multiple sets of carefully arranged fan-shaped nozzles form a three-dimensional flushing network without dead angles, ensuring that even the gaps inside the terminals of complex structures can be fully covered.

· Circulation filtration system: After spraying, the cleaning liquid will flow back through the collection tank at the bottom. After a set of multi-level (such as precipitation, filter bag, precision filter element) filtration system, the impurities in the liquid will be removed, the recycling of the cleaning liquid will be realized, and the cost of consumables will be significantly reduced.

· Material compatibility: All parts in contact with the cleaning solution are made of high-quality SUS304/316 stainless steel or high-grade engineering plastics, with excellent chemical corrosion resistance to ensure the long-term stable operation of the equipment.

The third stop: the wind blade technology of instant peeling water

· Module name: high-efficiency air cutting drying system

· Process description: After completing the spraying and rinsing the terminal with a large amount of liquid attached to the surface, most of the flowing water film on its surface must be removed before entering the drying oven. This is the core mission of the wind cutting system. The equipment has a built-in high-power centrifugal fan, which generates a stable and powerful airflow, and forms a uniform and high-speed "air blade" through an aerodynamically optimized narrow wind blade outlet.

· Technical highlights:

· Efficient drying: This invisible "wind blade" can instantly scrape off more than 90% of the residual moisture between the terminal surface and pins with extremely low energy consumption. This step is very important. It greatly reduces the heat load of the subsequent baking oven and improves the overall drying efficiency.

· Energy-saving design: Compared with traditional hot air drying, the energy consumption of air cutting at room temperature is extremely low, and the risk of water residues quickly scaling on the surface of the workpiece due to high temperature is avoided.

The fourth stage: uniform and thorough spiral hot air baking

· Module Name: Spiral Lifting Hot Air Drying Oven

· Process description: This is the final link to achieve "absolute drying". The ends that have been cut by air enter the unique spiral baking oven with the conveying system. The workpiece is continuously and evenly heated in the process of spiral climbing.

· Technical highlights:

· Advantages of spiral design: Compared with the traditional linear drying channel, the spiral structure greatly extends the effective drying path of the workpiece within a limited floor area, ensuring sufficient retention time, so that the heat can fully penetrate into every corner of the terminal.

· Precise temperature control system: PID intelligent temperature controller is used to cooperate with SSR solid-state relay, and the temperature control in the furnace is accurate to ±1℃, so as to avoid damage to the plastic parts of the terminal if the temperature is too high or the temperature is too low to dry. The heating method is usually high-efficiency electric heating, and it can be optionally heated with steam or natural gas.

· Uniform hot air circulation: The built-in high-temperature centrifugal fan and the uniquely designed air duct allow the hot air to circulate three-dimensionally in the furnace, ensuring that there is no dead angle of hot air, and each terminal can achieve a consistent drying effect.

End point: automatic unloading and collection

· The terminal blocks that are completely dried and meet the process requirements are smoothly output from the outlet of the spiral baking oven. Through the unloading slide or connecting the belt, they neatly fall into the finished product collection box, material plate or dock with the automated AGV trolley, and directly enter the next packaging or assembly process to realize the intelligent closed loop of the whole process.

---

Summary of the core advantages of the equipment

1. The whole process is automated, reducing costs and increasing efficiency: from online to offline, there is no need for manual intervention, and one person can take care of multiple devices, which greatly reduces labor costs and the risk of human errors, and improves production efficiency by more than 300%.

2. Excellent cleaning and drying effect: The triple process combination of "spraying + air cutting + spiral drying" ensures that cleaning is free of dead angles and drying is more thorough, and the one-time qualification rate of the product is as high as more than 99.9%.

3. Stable, reliable and durable: The key parts are made of internationally famous brands, and the main structure is made of high-quality stainless steel. The equipment design has a long life and a low failure rate to ensure the continuity of production.

4. Energy-saving and environmental protection, cost controllable: the cleaning liquid circulation filtration system greatly reduces the waste liquid emission and the amount of fresh detergent; the air cutting system effectively reduces the drying energy consumption, which meets the standards of modern green factories.

5. Flexible customization and strong adaptability: We are well aware of the different needs of different customers. Therefore, the size, conveying speed, cleaning pressure, drying temperature and time and other parameters of the equipment can be personalized and customized according to your specific workpiece and production beat.

---

Application field

This equipment is widely used in all kinds of terminal processing scenarios that require high-standard cleaning and drying:

· Automobile industry: cleaning of engine wiring harness, body control wiring harness, and new energy high-voltage wiring harness terminals.

· Electronics industry: post-welding cleaning of internal connectors and terminals of computers, communication equipment, household appliances, etc.

· industry and aerospace: electrical connection components with high reliability requirements.

· New energy: electrical connectors inside photovoltaic inverters, energy storage systems and charging piles.

Conclusion:

Choosing our fully automatic terminal block cleaning and drying all-in-one machine is not only a high-performance equipment, but also a reliable partner to improve product quality, optimize the production process, and reduce comprehensive operating costs. Let's join hands and move to a new height of intelligent manufacturing.

Recommended Products

Recently Viewed

Contact Us

Guangdong Shunde Jiaheda Cleaning Equipment Co., L