Welcome!

Guangdong Shunde Jiaheda Cleaning Equipment Co., L

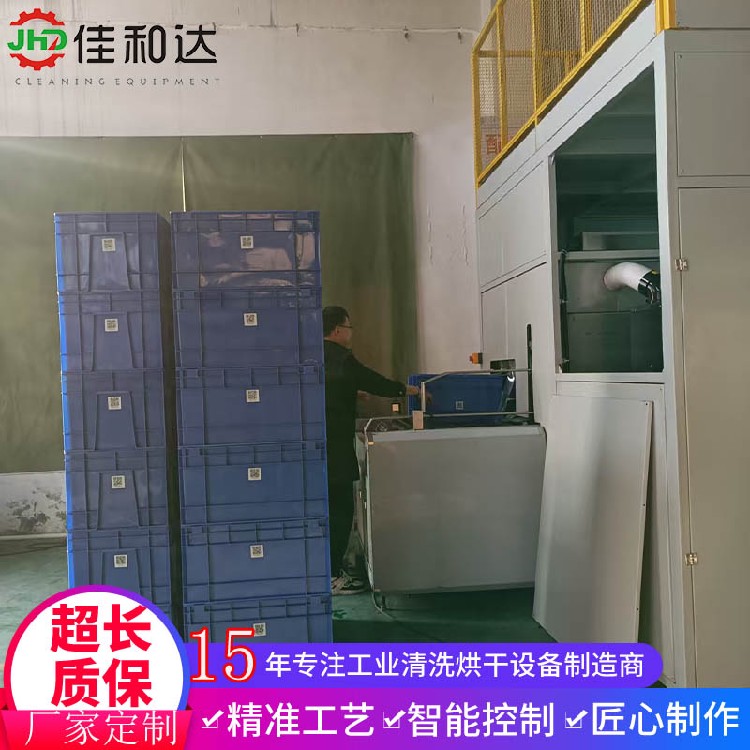

Main products: Ultrasonic cleaning machine , spray cleaning machine, high-temperature drying line, oil removal cleaning line, hanging cleaning and drying line, gantry automatic cleaning line, wax removal cleaning and drying line, box washing machine, high-pressure washing machine, flat brush cleaning machine, tunnel drying oven, natural gas cleaning and drying equipment

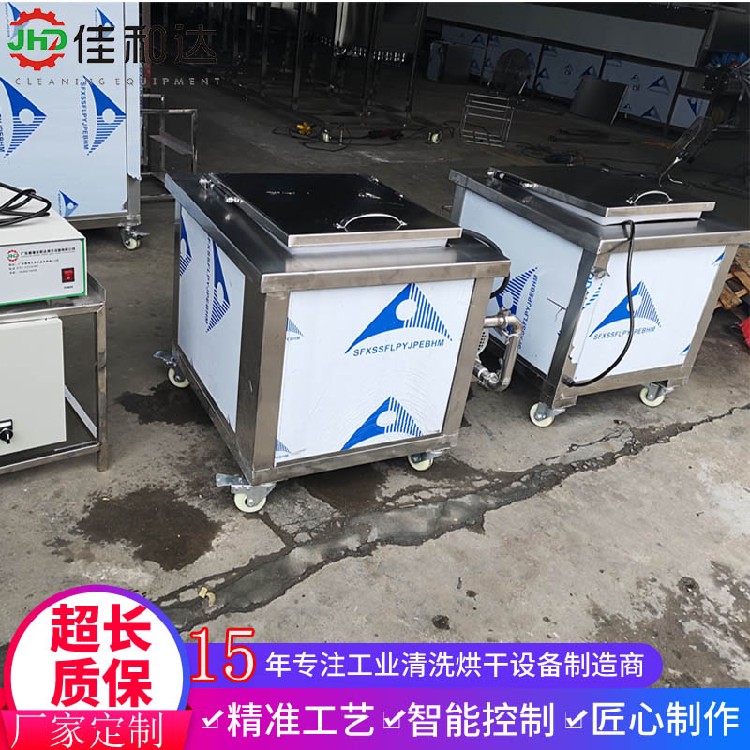

Dual-tray ultrasonic cleaning machine

Product Description

I. What is a dual-channel ultrasonic cleaning machine?

A dual-slot ultrasonic cleaning machine is a specialized cleaning device that integrates two separate cleaning slots (usually called a "cleaning slot" and a "washing slot"). It uses ultrasonic high-frequency vibration to create a "cavitation effect" in the liquid, enabling microscopic cleaning of surfaces and cracks. Its core design concept is "separation of cleaning and washing," which fundamentally solves the cross-contamination and secondary pollution problems that can occur during the cleaning process of single-slot machines, and is especially suitable for demanding cleaning processes.

II. Core advantages: why choose dual slots?

1. Eliminate cross-contamination: This is the greatest advantage. The first trough is used for primary cleaning using a cleaning agent, and the second trough is for holding pure or deionized water for washing. It prevents dirt that has been dissolved by the cleaning agent from sticking to the workpiece again.

2. Improving work efficiency: The operator can while cleaning in slot 1, bleach and remove the workpiece which has been cleaned in slot 2, achieving assembly line operations and greatly improving the efficiency of batch processing.

3. Guaranteed cleanliness: The independent washing tank ensures that after chemical cleaning, the workpiece can be thoroughly washed clean, free of residues of cleaning agents, and achieves a higher cleanliness standard.

4. Extend solution life: The cleaning agent inside the washing tank can be reused many times, while the water in the washing trough is relatively clean and replaced differently, helping to reduce the cost of consumables.

5. High application flexibility: two slots can be set to different operating modes. For example, a cleaning trough can be heated and added with a powerful cleaning agent, while a washing trough only uses normal-temperature water or undergoes ultrasonic cleaning to suit the needs of different materials and dirt types.

III. Structure and working principle

· Structure:

· fuselage: integrated two trunk casings.

· Cleaning tank: Typically a main tank with a built-in ultrasonic transducer that can be heated and used to add cleaning agents for strong decontamination.

· Cleaning chute: usually a side chute, also with a built-in ultrasonic transducer (or a slightly lower power), used primarily for water cleaning.

· Ultrasonic generator: The core power source that converts electrical energy into high-frequency electrical signals.

· Transducer: Converts high-frequency electrical signals into mechanical vibration (ultrasonic).

· Control system: usually includes timers, temperature controllers, power regulators, etc. for the precise control of the cleaning process.

· How it works:

The ultrasonic generator produces high-frequency electrical signals, which are converted by a transducer into mechanical vibration of the same frequency. This vibration propagates through the tank wall into the cleaning liquid, causing the liquid to produce tens of thousands of tiny real air bubbles ("cavitated bubbles"). These bubbles are rapidly formed and violently rupture under the change of pressure, generating impact force of more than 1000 atmospheres and high temperature in an instant, violently impacting the surface and cracks of the workpiece, thereby quickly stripping, emulsifying and dispersing stubborn dirt, oil stains, dust and so on to achieve the effect of thorough cleaning.

IV. Main areas of application

The dual-channel design allows it to perform well in areas where there are grading requirements for cleanliness or where pollution needs to be avoided:

· Precision industry: cleaning precision machine parts, semiconductors silicon, electronic PCB circuit board, medical equipment (such as surgical forceps, endoscopes).

· Laboratory and scientific research: Cleaning experimental vessels (cups, test tubes, capacity bottles), scientific samples, sensors, etc. to ensure that there are no residues and that the results of the experiment are not affected.

· Jewelry & Watch Industry: One trough is strongly cleaned of oil and dirt, and the second trough is cleaned of water to restore luster, avoiding the potential effects of chemicals on precious stones and metals.

· Optical industry: Wash eyeglass lenses, camera lenses, optical lenses, etc. to avoid scratches and contamination.

· Automotive & Aerospace: cleaning carburetors, nozzles, engine parts, precision bearings, etc.

V. SHOPPING GUIDE

When selecting a dual-channel ultrasonic cleaning machine, pay attention to the following parameters:

1. Tank capacity and size: Choose based on the size and volume of the workpiece you often clean. Make sure the internal size of the trough accommodates your items.

2. Ultrasonic frequency:

· Low frequency (25-40kHz): strong energy, great impact, suitable for cleaning heavy oil, stubborn dirt metal hard parts.

· High frequency (more than 80kHz): The bubbles are more dense and gentle, suitable for cleaning precision, fine structure workpieces, such as semiconductors, optical lenses, electronic products, can reduce cavitation corrosion.

· Ideally, the two slots can be set at different frequencies to suit the needs of different cleaning phases.

3. Heating function: Heating can significantly improve the activity of most cleaning agents, accelerate the dissolution of dirt, and improve the cleaning efficiency.The general heating temperature range is between 30-80 ° C.

4. Material: The inner groove material is preferred for 304 or 316 stainless steel, which is resistant to corrosion, easy to clean and has a long life.

5. Power: Includes ultrasonic power and heating power. Power is not the greater the better, but enough power is the basis for guaranteeing the cleaning effect and heating speed. Required to match the capacity of the tank.

6. Control System: Digital control is more precise than mechanical knobs. Check whether there are digital timing, temperature control, power regulation, frequency switching, etc.

VI. CAUSES OF USE

1. Level requirements: Be sure to inject enough water or cleaning fluid into the tank. The surface height should be at least two-thirds of the inner tank, but not overfull. Normally the inner tank has a maximum level line marked. Too low a liquid level can damage the machine.

2. Choose the right cleaning agent: Choose the appropriate professional ultrasonic cleaning agent according to the cleaning object and the type of dirt. Do not use strong acids, alkalis, flammable and explosive liquids (such as gasoline, alcohol).

3. Placement of workpiece: Use a dedicated cleaning basket to avoid direct contact between the workpiece and the bottom of the trough to avoid affecting vibration and causing wear. Small workpieces can be placed in a net bag to prevent loss.

4. Regular maintenance: After each use, please clean the loose dirt in the tank in time to keep the inner tank clean. When not used for a long time, the liquid in the tank should be emptied and kept dry.

Recommended Products

Recently Viewed

Contact Us

Guangdong Shunde Jiaheda Cleaning Equipment Co., L