Welcome!

Guangdong Shunde Jiaheda Cleaning Equipment Co., L

Main products: Ultrasonic cleaning machine , spray cleaning machine, high-temperature drying line, oil removal cleaning line, hanging cleaning and drying line, gantry automatic cleaning line, wax removal cleaning and drying line, box washing machine, high-pressure washing machine, flat brush cleaning machine, tunnel drying oven, natural gas cleaning and drying equipment

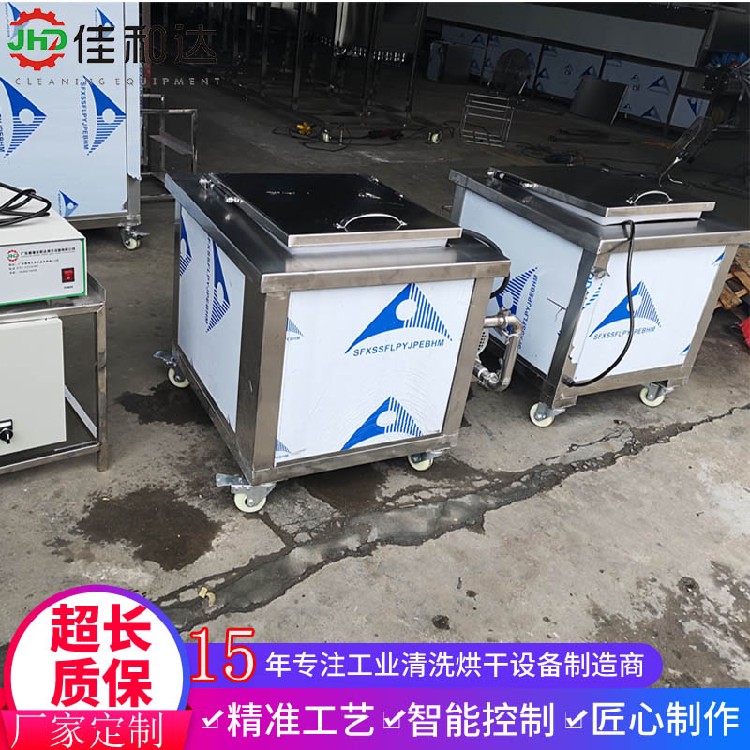

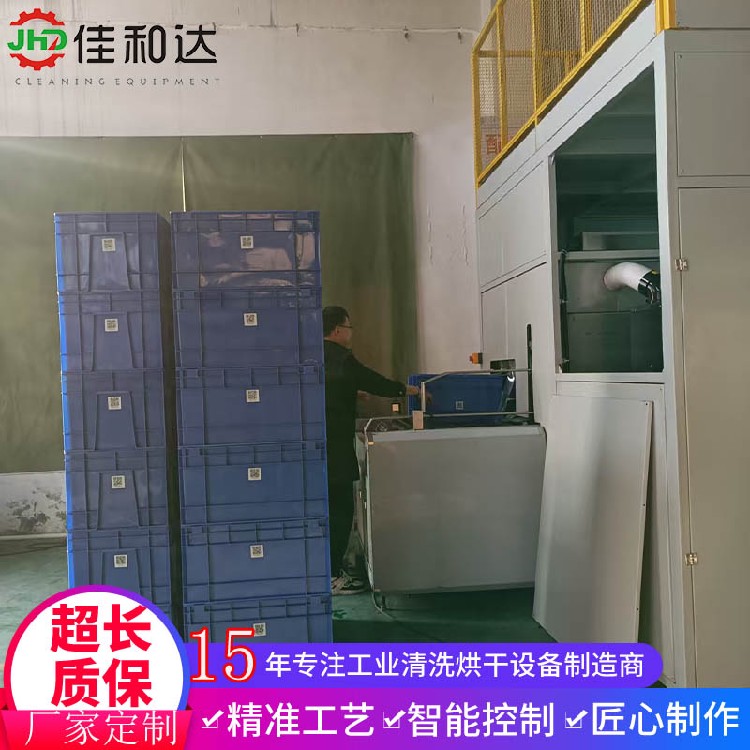

Five-slot and a half automatic ultrasonic cleaning machine

Product Description

The five-slot and a half automatic ultrasonic cleaning machine is an efficient cleaning equipment specially designed for precision parts, electronic components, hardware tools and other industries. It adopts multi-slot cleaning technology, combined with ultrasonic high-frequency vibration and automated transmission technology, to realize the integration of the whole process of decontamination and rinsing, greatly improving cleaning efficiency and cleanliness, and reducing labor costs.

Core advantages:

1. Five-trough intelligent cleaning: including three ultrasonic cleaning tanks and two washing tanks to ensure that the stains are peeled off layer by layer and there is no residue.

2. Semi-automatic operation: After manual loading and unloading, the equipment automatically completes the cleaning process, which is labor-saving and efficient, suitable for small and medium-sized production needs.

3. Powerful ultrasonic cleaning: high-frequency ultrasonic (optional 40kHz) produces a cavitation effect, completely removing oil stains, dust and polishing paste in gaps and holes.

4. Energy saving and environmental protection: built-in circulation filtration system to reduce the consumption of cleaning agents; acid- and alkali-resistant materials, adapt to a variety of solvents and reduce the pressure of wastewater treatment.

5. Customized configuration: adjustable temperature (room temperature ~80��C), time (0-30 minutes free setting), adapt to the needs of different materials and workpieces.

Application scenario:

- Electronics industry: PCB board, semiconductor component de-flux, de-oxidation layer.

- Precision manufacturing: degreasing and polishing of metal parts such as bearings and gears.

The five-slot and a half-automatic design achieves a balance between efficiency and cost, which is ideal for small and medium-sized enterprises.

Support non-standard customization, welcome to consult!

Recommended Products

Recently Viewed

Contact Us

Guangdong Shunde Jiaheda Cleaning Equipment Co., L