Welcome!

Best Price Electrical Wiring Metal Steel Flexible Conduit with PVC Coated

Product Description

As an important component of the power transmission system, the safe and stable operation of cable conduits is of great significance for ensuring the reliability and continuity of power supply. In future development, cable conduits will continue to play a crucial role in power transmission, contributing to the prosperity and stability of society. The testing of cable conduits covers multiple aspects such as material, size, bending performance, sealing performance, insulation performance, compression resistance, and impact resistance. The purpose of these tests is to ensure that the quality of cable conduits meets relevant standards and requirements, thereby ensuring the stability and safety of power transmission.

The size and specifications of cable conduits must comply with design requirements and relevant standards. The test includes the diameter, length, wall thickness, bending radius, etc. of the catheter. Use a bending tester or bending block for testing to simulate the bending of cable conduits in actual use. Bend the conduit within the specified bending radius and observe whether there are any cracks, indentations, or other deformations on its surface, in order to determine whether its flatness meets the standard requirements. For cable conduit joints, sealing tests are required to ensure they do not leak. The testing methods include hydrostatic testing and pneumatic testing, which observe the sealing performance of the joint by applying a certain amount of pressure.

Recommended Products

Recently Viewed

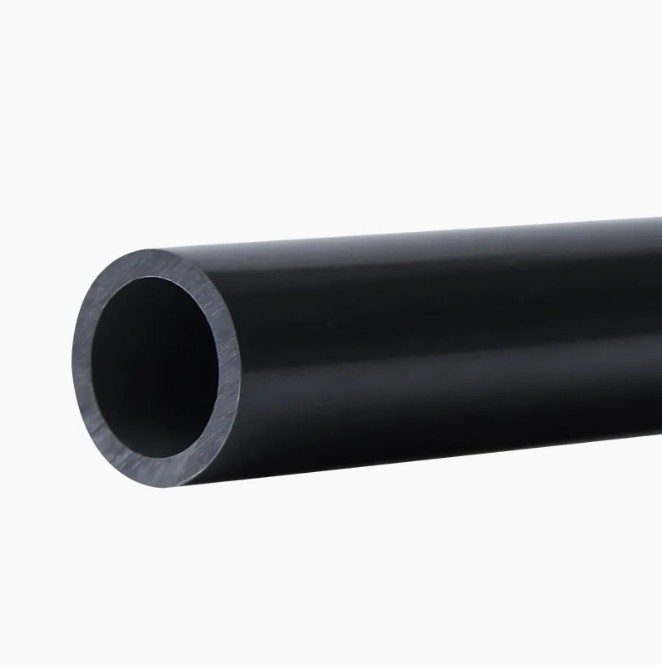

Flexible cable wire protection hose cable covering PVC Cable Conduits

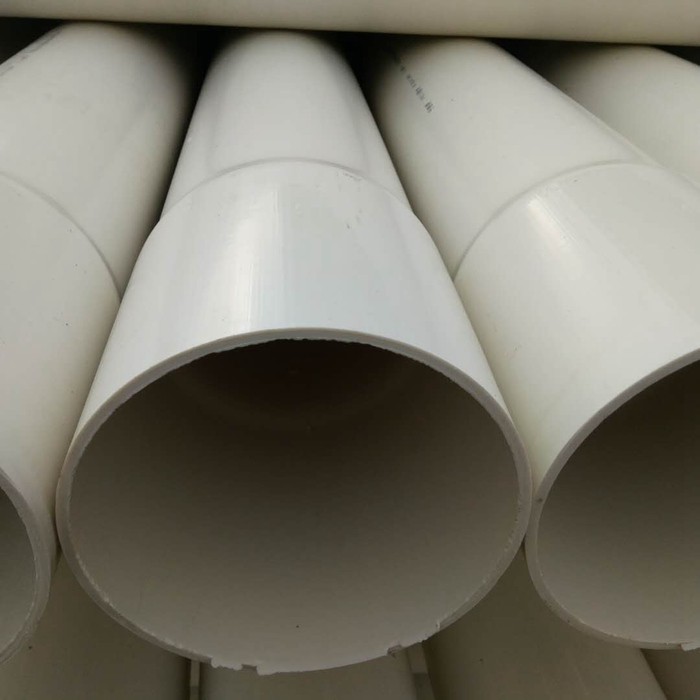

Flexible cable wire protection hose cable covering PVC Cable Conduits Large diameter pvc pipe supplier

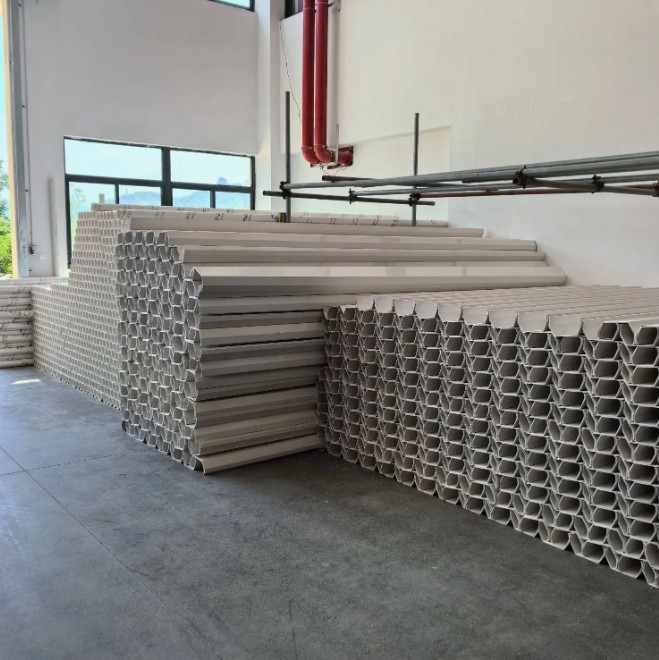

Large diameter pvc pipe supplier Cable Conduits: Secure, Organized Pathways for Reliable Wiring Systems

Cable Conduits: Secure, Organized Pathways for Reliable Wiring Systems Cable Conduits: Engineered Protection & Order for Your Wiring Infrastructure

Cable Conduits: Engineered Protection & Order for Your Wiring Infrastructure Cable Conduits: The Essential Pathway for Protected & Organized Wiring

Cable Conduits: The Essential Pathway for Protected & Organized Wiring

Contact Us

Cangzhou Honghu Electrical Manufacturing Co., Ltd.