Welcome!

China Supplier PVC Coated Waterproof Flexible Tube Metal Flexbile Conduit

Product Description

The size and specifications of cable conduits must comply with design requirements and relevant standards. The test includes the diameter, length, wall thickness, bending radius, etc. of the catheter. Use a bending tester or bending block for testing to simulate the bending of cable conduits in actual use. Bend the conduit within the specified bending radius and observe whether there are any cracks, indentations, or other deformations on its surface, in order to determine whether its flatness meets the standard requirements. For cable conduit joints, sealing tests are required to ensure they do not leak. The testing methods include hydrostatic testing and pneumatic testing, which observe the sealing performance of the joint by applying a certain amount of pressure.

Some cable conduits are made of flame-retardant materials, which have good fire resistance and can effectively prevent the spread of fire in the event of a fire, protecting the cables from damage. The design of cable conduits has a certain degree of flexibility, can adapt to the installation needs of different terrains and environments, and is convenient for construction and maintenance. The cable conduit is made of high-strength materials, which have a long service life and good durability, and can operate stably for a long time in harsh environments.

Recommended Products

Recently Viewed

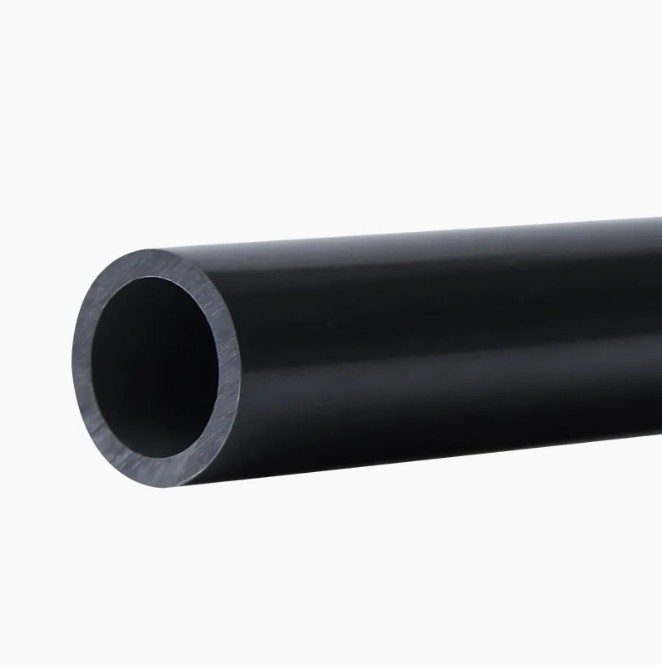

Flexible cable wire protection hose cable covering PVC Cable Conduits

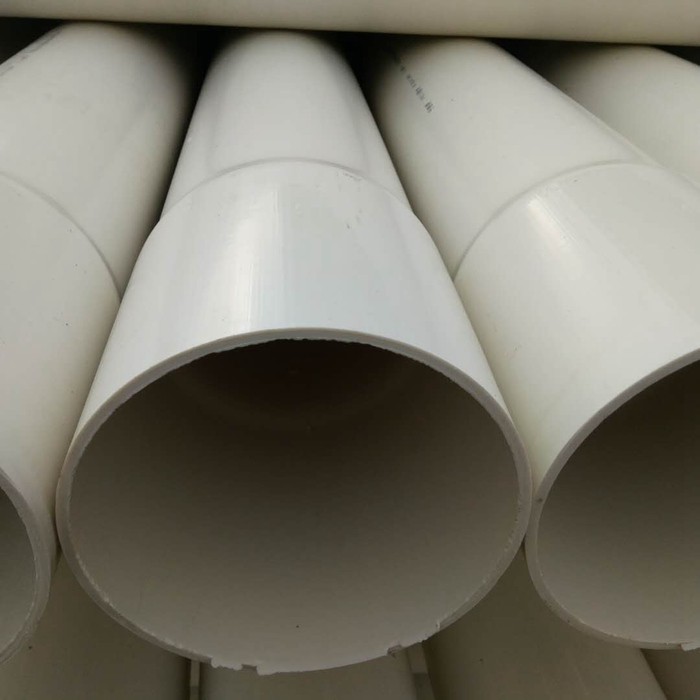

Flexible cable wire protection hose cable covering PVC Cable Conduits Large diameter pvc pipe supplier

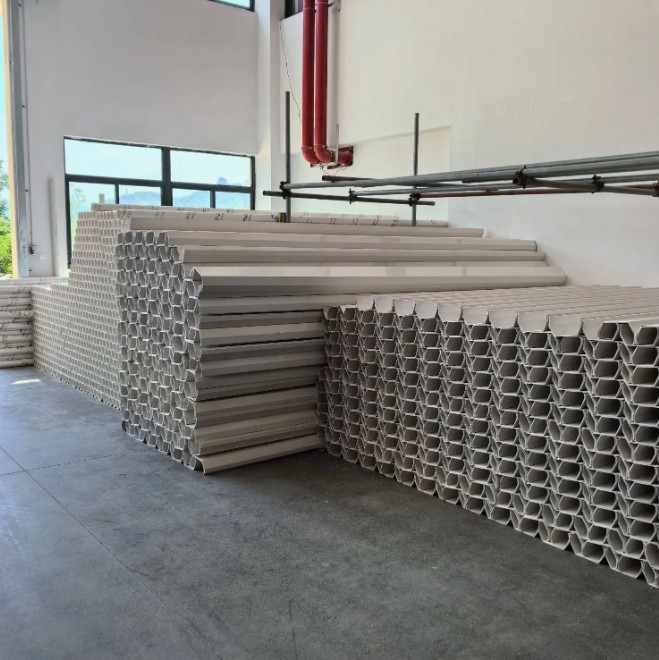

Large diameter pvc pipe supplier Cable Conduits: Secure, Organized Pathways for Reliable Wiring Systems

Cable Conduits: Secure, Organized Pathways for Reliable Wiring Systems Cable Conduits: Engineered Protection & Order for Your Wiring Infrastructure

Cable Conduits: Engineered Protection & Order for Your Wiring Infrastructure Cable Conduits: The Essential Pathway for Protected & Organized Wiring

Cable Conduits: The Essential Pathway for Protected & Organized Wiring

Contact Us

Cangzhou Honghu Electrical Manufacturing Co., Ltd.