Welcome!

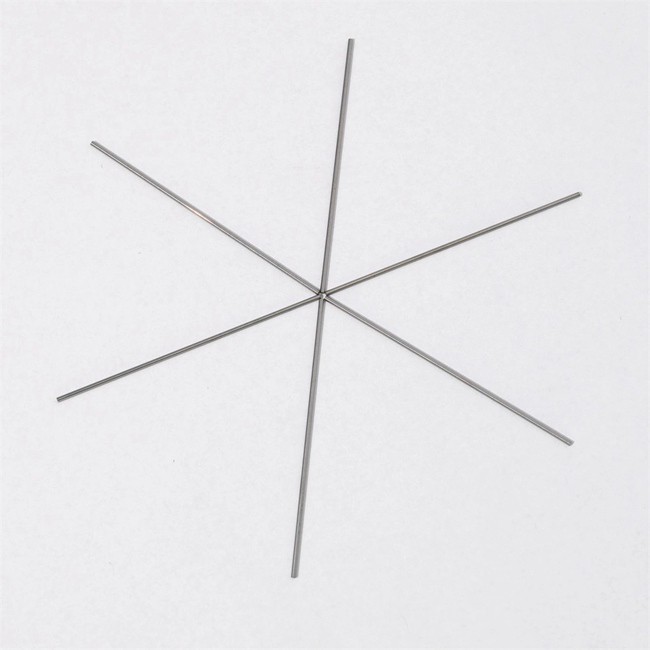

China Manufacturer Solid Cutting Drilling Milling Tools Tungsten Carbide Rod

Product Description

The production process of hard alloy rods mainly includes milling, formulation, wet grinding, mixing, crushing, drying, sieving, adding forming agents, re drying, sieving to obtain a mixture, granulation, pressing, forming, low-pressure sintering, external grinding and precision grinding (blank does not have this process), size inspection, packaging, warehousing and other steps. Among them, low-pressure sintering technology is one of the key technologies for producing high-quality hard alloy rods.

Hard alloy rod, also known as hard alloy round rod or tungsten steel rod, is an alloy material made of hard compounds of refractory metals and bonding metals through powder metallurgy process. Hard alloy rods have extremely high hardness and wear resistance, with hardness comparable to diamond and excellent wear resistance. In addition to high hardness, hard alloy rods also have good strength and toughness, and can withstand large mechanical stresses and impacts.

Recommended Products

Recently Viewed

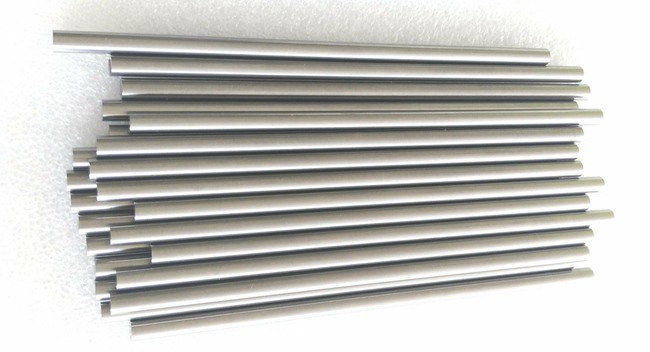

chinese supplier Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod

chinese supplier Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod China Manufacturer High Quality Super Hard Solid Tungsten Carbide Rod

China Manufacturer High Quality Super Hard Solid Tungsten Carbide Rod Wholesale Price Solid Cutting Drilling Milling Tools Tungsten Carbide Rod

Wholesale Price Solid Cutting Drilling Milling Tools Tungsten Carbide Rod China Manufacturer Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod

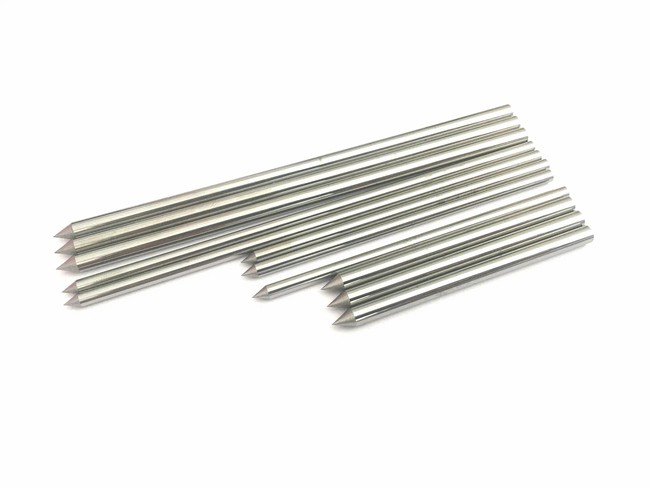

China Manufacturer Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod Selected Chinese High Quality Super Hard Solid Tungsten Carbide Rod

Selected Chinese High Quality Super Hard Solid Tungsten Carbide Rod

Contact Us

DongGuan Dason Electric Company