Welcome!

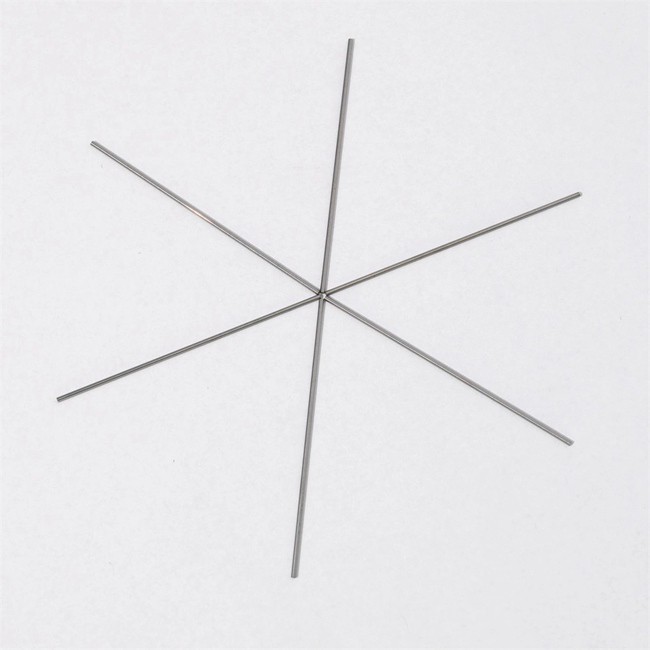

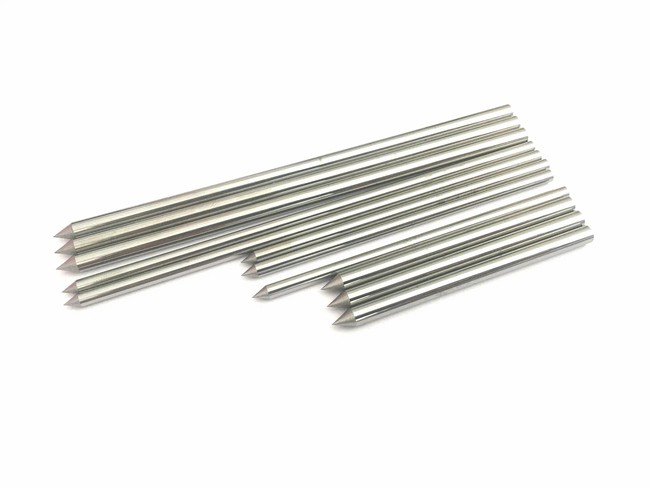

Selected Chinese High Quality Super Hard Solid Tungsten Carbide Rod

Product Description

Hard alloy rods are key materials for manufacturing various cutting tools such as turning tools, milling cutters, planers, drills, boring tools, etc. These cutting tools are widely used in industries such as metal processing, wood processing, and plastic processing to efficiently and accurately cut various materials. Hard alloy rods can be used to manufacture molds, such as stamping molds, extrusion molds, and injection molds. Due to its high hardness and wear resistance, hard alloy molds can withstand high pressure and frequent impacts, extending the service life of the molds.

Tungsten rod, also known as tungsten alloy rod, is a material made by refining metal powder at a specific high temperature through special high-temperature powder metallurgy technology.

Name: Tungsten Bar

Nickname: Tungsten Alloy Rod

Main components: Depending on the formula, tungsten alloy rods may contain various metal elements such as tungsten (W), nickel (Ni), molybdenum (Mo), iron (Fe), etc., such as WMoNiFe alloy or tungsten alloy with a ratio of 90% W, 4% Ni, 4% Mo, 2% Fe.

Recommended Products

Recently Viewed

chinese supplier Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod

chinese supplier Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod China Manufacturer High Quality Super Hard Solid Tungsten Carbide Rod

China Manufacturer High Quality Super Hard Solid Tungsten Carbide Rod Wholesale Price Solid Cutting Drilling Milling Tools Tungsten Carbide Rod

Wholesale Price Solid Cutting Drilling Milling Tools Tungsten Carbide Rod China Manufacturer Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod

China Manufacturer Mirror Surface End Mill Drill Dia20mm Solid Tungsten Carbide Polishing Rod Selected Chinese High Quality Super Hard Solid Tungsten Carbide Rod

Selected Chinese High Quality Super Hard Solid Tungsten Carbide Rod

Contact Us

DongGuan Dason Electric Company