Welcome!

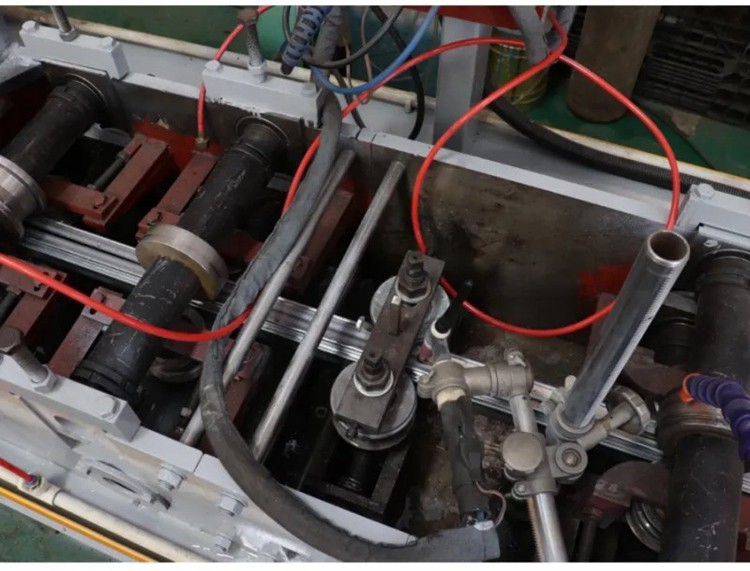

Four-roller hydraulic CNC plate rolling machine

Product Description

Four-roller hydraulic CNC plate rolling machine

Use and working principle of CNC four-roller plate rolling machine

The CNC four-roller plate rolling machine is a machine used to roll and form metal sheets. It is mainly used to process plates of various specifications and thicknesses. It is widely used in the fields of shipbuilding, manufacturing, construction, etc.

The working principle of the CNC four-roller plate rolling machine is to drive the metal sheet to roll and form through four rollers. Among them, the position of the two lower rollers can be adjusted, so that the metal sheet is continuously rolled and stretched, thereby achieving the effect of processing and forming.

Product Features

1. The straight edge can be rolled shorter than any other plate rolling machine (good pre-bending)

2. It is easy to add options such as plate handling equipment (conveyor table, loader)

3. The entire rolling process can be completed with only one rolling, including pre-bending on both sides

4. Only one operator is required (this is almost impossible for any three-roller plate rolling machine)

5. Usually 50%-80% more productive than three-roller or any other form of plate rolling machine

6. Plate rolling is easy to operate and does not require a high level of operator skill

7. Perfect geometric design, high precision and good roundness of the rolled workpiece

8. Plate is fed horizontally (especially helpful for feeding long plates)

9. The plate is always clamped by the upper and lower rollers during the rolling process (no sliding)

10. The design is more suitable for rolling cones than three-roller or other forms of plate rolling machines

11. There is only margin at one end of the plate feeding

12. The calibration roller on the back of the plate is instantly aligned

13. Best suited for CNC operation

Recommended common models of CNC four-roll plate rolling machine

1. W12 series CNC four-roll plate rolling machine

The W12 series CNC four-roll plate rolling machine has the characteristics of high precision, high efficiency and high reliability, and is mostly used for plate processing in large ships, railways, bridges, petroleum, chemical industry, metallurgy, power and other industries. This series of CNC four-roll plate rolling machines is not only simple to operate, but also has a high degree of automation, which can meet the needs of various metal plate processing.

2. W11 series CNC four-roll plate rolling machine

The W11 series CNC four-roll plate rolling machine is one of the most common models on the market. It is suitable for processing metal plates of various specifications and thicknesses, and is widely used in construction, manufacturing, metallurgy, power and other fields. The advantages of this series of CNC four-roll plate rolling machines are simple operation, stable and reliable performance, and relatively affordable prices.

3. JW11 series CNC four-roll plate rolling machine

JW11 series CNC four-roll plate rolling machine is a multifunctional metal plate processing equipment with automatic adjacent edge pressing technology and cam-type coiling technology. It is easy to operate and has high processing efficiency. This series of CNC four-roll plate rolling machines is suitable for processing metal plates of various specifications and thicknesses, such as petrochemicals, light industry, metallurgy, shipbuilding, rail transportation and other fields.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.