Welcome!

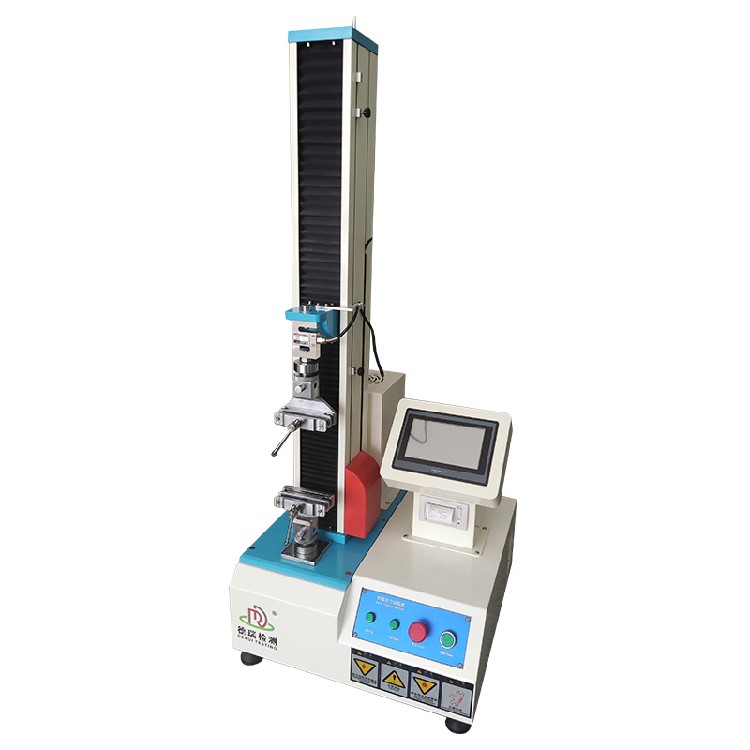

Multi-functional single-column tensile testing machine

Basic Info

| Displacement Accuracy | ±0.05 mm | Load Capacity | 0.5 kN, 1 kN, 5 kN, 10 kN, | Max Test Stroke | 600 mm, 1000 mm (customizable) |

|---|---|---|---|---|---|

| Model | DR-L201-2 | Power Supply | 220V, 50/60Hz (customizable for different regions) | Speed Resolution | 0.01 mm/min |

| Test Frame Structure | Single-column, high-stability frame | Testing Method | Tensile, Compression, Bending, Shear (depending on fixtures) | Testing Standards | ISO 527, ASTM D638, JIS K7113, GB/T 1040 |

Product Description

A multi-functional single-column tensile testing machine is a versatile device designed to perform a variety of mechanical tests on materials, including tension, compression, bending, and shear. These machines are widely used in industries such as aerospace, petrochemical, and automotive manufacturing for testing the mechanical properties of materials and products.

Key Components and Their Functions

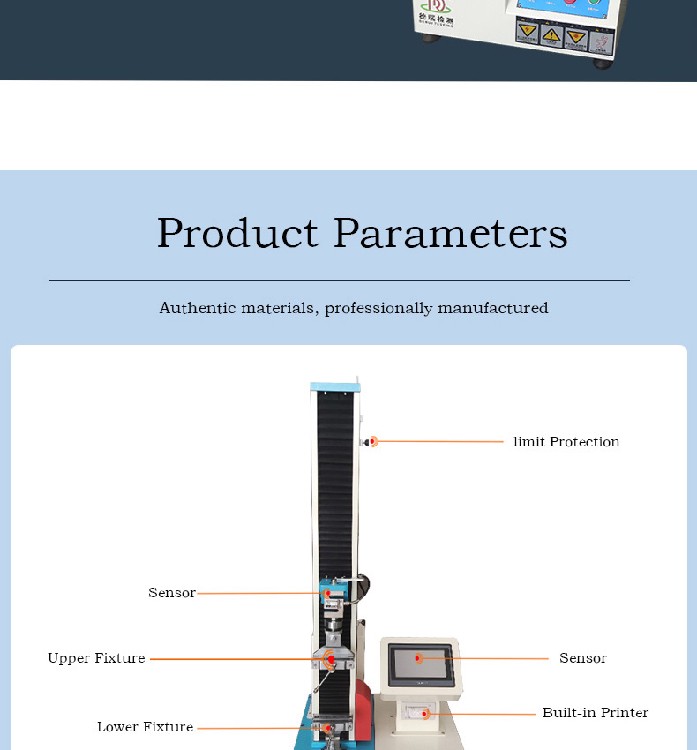

- Host Structure: Provides the support framework, ensuring stability and reliability during testing.

- Drive System: Offers precise control over the loading and unloading process, capable of various loading modes.

- Measurement System: Records and monitors data such as force, displacement, and deformation in real-time.

- Control System: Manages the loading speed, mode, and data acquisition frequency, often equipped with control software for automation.

- Clamp System: Fixes the specimen, ensuring stability and reliability during the test.

- Safety System: Monitors for abnormal conditions and can automatically stop the test to ensure operator and equipment safety.

Applications

- Material Testing: Used to test the mechanical properties of metals, plastics, rubber, textiles, and composites.

- Quality Control in Manufacturing: Ensures that materials meet the required mechanical standards in industries like automotive and aerospace.

- Research and Development: Essential for testing new materials and technologies in a laboratory setting.

Technical Parameters

- Maximum Testing Force: Varies depending on the model, with options to customize for higher or lower capacities.

- Loading Precision: Typically ±0.5% or higher, ensuring accurate and reliable test results.

- Displacement Precision: High precision in measuring the movement of the specimen during the test.

- Force Resolution: The smallest unit of force that the machine can measure, often 0.01 N or better.

- Maximum Stroke: The maximum distance the moving beam can travel, usually up to 1000 mm.

- Test Speed: Adjustable speed range for the test, allowing for flexibility in testing different materials.

- Data Acquisition Frequency: The rate at which data is collected during the test, ensuring detailed and accurate results.

- Display and Control System: Modern systems often feature digital displays and software controls for ease of use and data analysis.

Conclusion

Multi-functional single-column tensile testing machines are indispensable tools in material science and engineering, providing precise and reliable data for a wide range of testing applications. Their ability to perform multiple types of tests with high accuracy makes them valuable assets in both industrial and research settings.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.