Welcome!

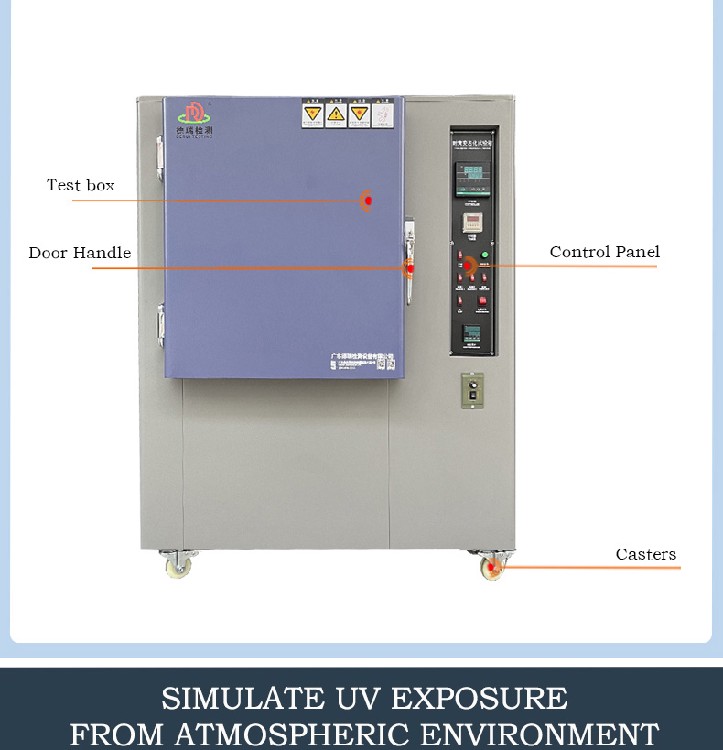

Intelligent control yellowing-resistant aging test chamber

Basic Info

| Chamber Material | SUS304 stainless steel, corrosion-resistant materials | Light Intensity | 300W/m² to 1500W/m² (adjustable) | Light Source | UVA/UVB lamps, fluorescent lamps, or LED simulated sunlight |

|---|---|---|---|---|---|

| Model | DR-H303 | Model Type | Yellowing-Resistant Aging Test Chamber | Power Supply | AC 220V, 50/60Hz (customizable for different regions) |

| Temperature Range | 40°C to 90°C (adjustable) | Test Chamber Size | 800mm (W) x 800mm (D) x 900mm (H), customizable | Test Duration | 1 hour to 1000 hours (user-adjustable) |

Product Description

The intelligent control anti yellowing aging test chamber is a device designed to simulate and accelerate the discoloration (especially yellowing) and aging process of materials under long-term exposure to environmental factors such as light, heat, and humidity. It is widely used in industries such as plastics, rubber, coatings, textiles, electronic components, etc., to help evaluate the weather resistance and lifespan of products. This type of test chamber can accelerate the reproduction of the aging effects that may occur on materials in the natural environment by precisely controlling the internal environmental conditions, thereby shortening the testing time and providing reliable data support.

main features

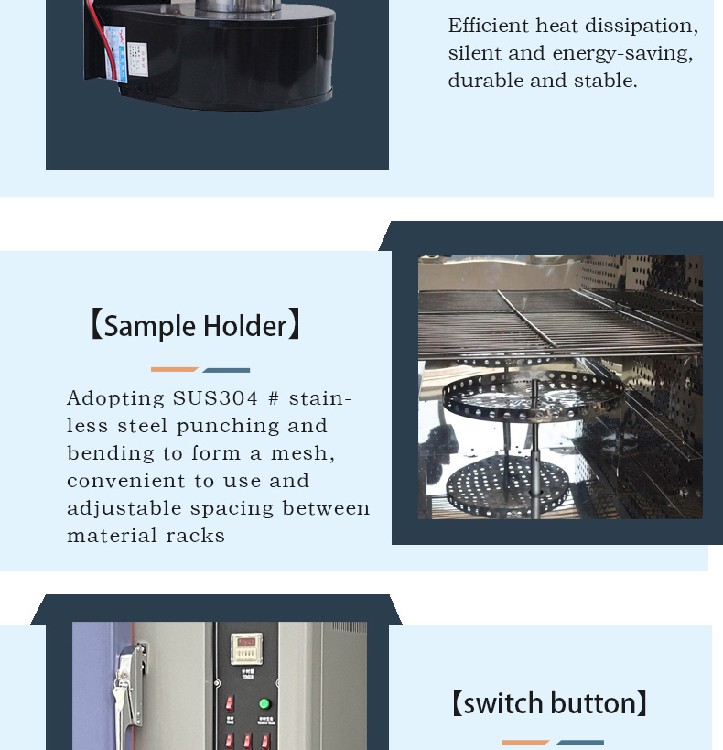

Intelligent control system: Adopting advanced computer or PLC control system, it can automatically adjust parameters such as temperature, humidity, and light intensity to ensure consistency and repeatability of testing conditions.

Multi light source selection: Equipped with multiple types of light sources (such as UV lamps, xenon lamps, fluorescent lamps, etc.) to simulate different solar radiation spectra, suitable for aging testing needs of different materials.

Accurate temperature and humidity control: Equipped with high-precision temperature and humidity sensors and control devices, it can set and maintain stable environmental conditions over a wide range.

Long term continuous operation: designed for long-term uninterrupted work, with good stability and durability, suitable for long-term aging experiments.

Safety protection measures: including over temperature protection, leakage protection, emergency stop button and other functions to ensure the safety of operators.

Data recording and analysis: The integrated data acquisition system can record various parameters in real-time during the testing process, and perform data analysis and report generation through software.

Functions and Applications

Accelerated aging test: By strengthening environmental conditions to accelerate the aging process of materials, information about the product's service life can be quickly obtained.

Color change monitoring: Built in colorimeter or other optical measurement tools are used to monitor the color change of the sample, especially the degree of yellowing.

Compliant with international standards: According to ISO, ASTM, DIN and other international standards are used for manufacturing to ensure the validity and comparability of test results.

Diversified testing modes: In addition to basic yellowing resistance testing, other types of aging tests can also be conducted, such as wet heat cycling, salt spray corrosion, etc., by simply replacing the corresponding modules or settings.

Scope of application

The intelligent control anti yellowing aging test box is suitable for the following fields:

Plastic and rubber industry: Evaluating the ability of polymer materials and their products to maintain performance over long-term use.

Coatings and Ink Industry: Testing the durability and aesthetics of coatings, paints, printing inks, etc. in outdoor environments.

Textile industry: Verify the fading and damage of fiber fabrics under light and climate conditions.

Electronic product industry: Ensure that electronic components can still function properly under harsh environmental conditions, especially for outdoor equipment.

Building materials industry: Check the stability of building exterior wall materials, roof materials, etc. under long-term exposure to natural environments.

Selection precautions

When choosing an intelligent control anti yellowing aging test box, the following aspects should be considered:

Clear testing requirements: Determine key parameters such as light source type, temperature range, humidity level, etc. based on specific testing purposes.

Accuracy requirements: Clearly define the required measurement accuracy, especially for high-end research or strict quality inspection scenarios.

Additional functional requirements: such as the need for additional testing modules (such as salt spray corrosion, wet heat cycling, etc.), or non-contact optical measurement equipment.

Space and budget constraints: Reasonably plan the layout of laboratory space and make the best choice based on budget.

Brand and after-sales service: Prioritize selecting brand suppliers who provide excellent technical support and service networks to ensure timely assistance in case of problems encountered during long-term use.

In summary, the intelligent control anti yellowing aging test box plays an important role in multiple industries with its precise environmental control capabilities and diverse testing functions, providing solid technical support for product quality and reliability.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.