Welcome!

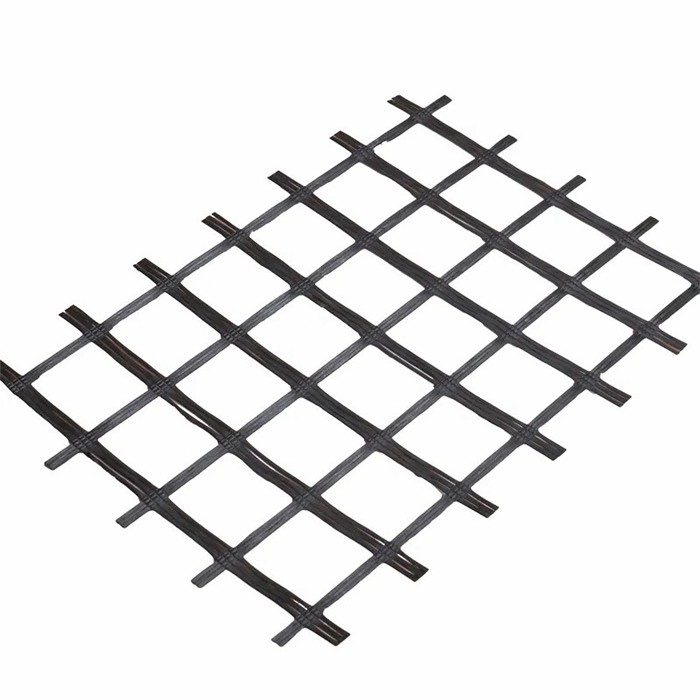

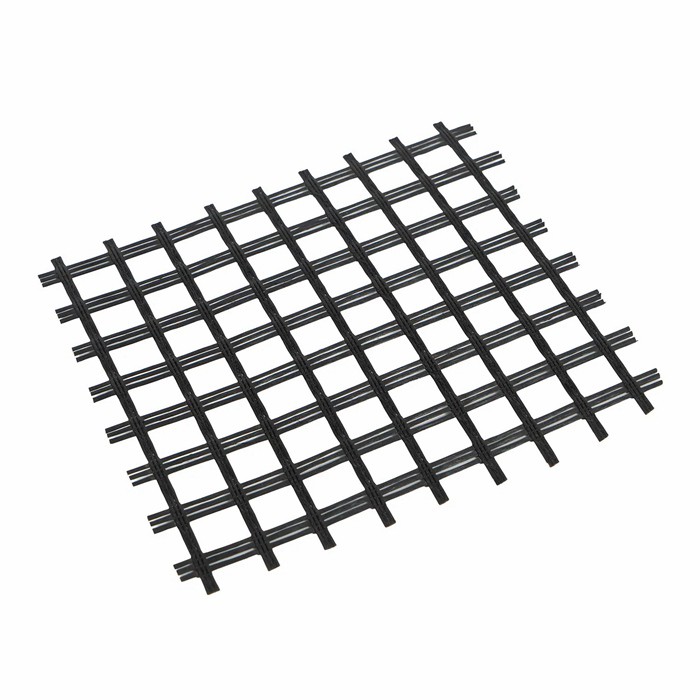

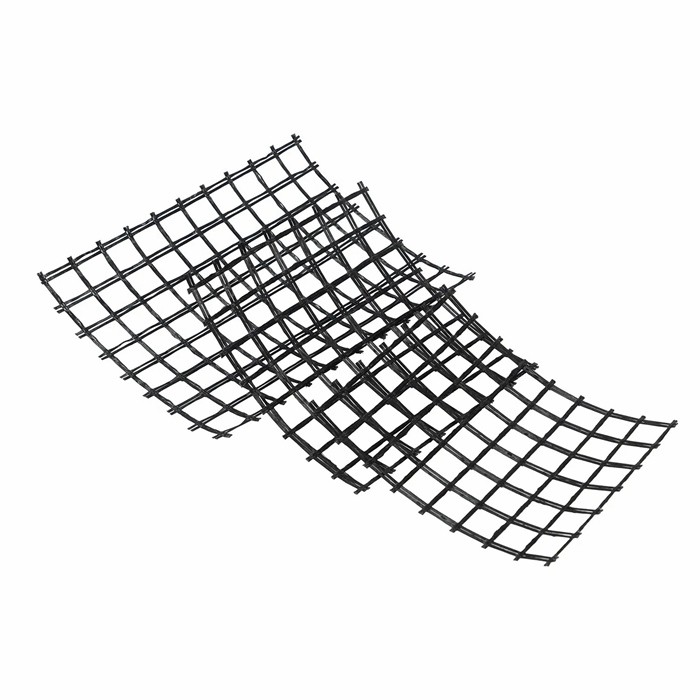

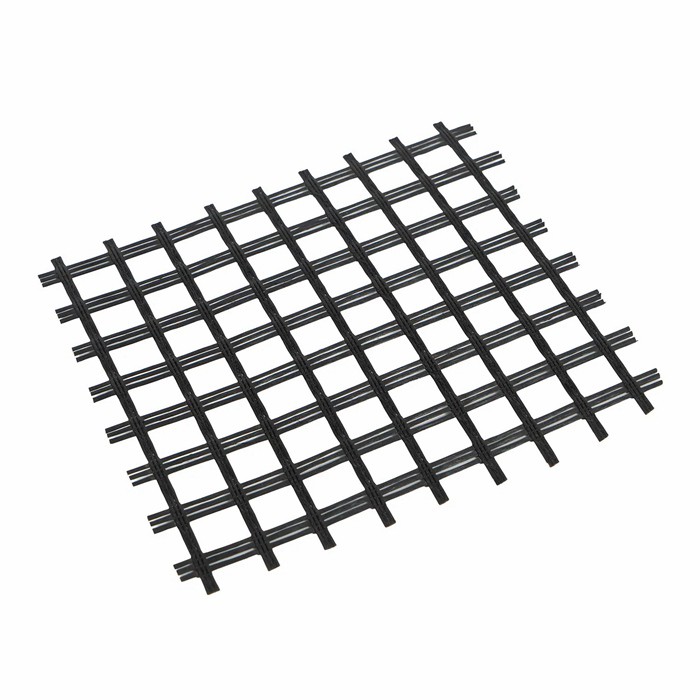

Fiberglass Geogrid: Engineered Reinforcement for Infrastructure

Basic Info

| Application | Asphalt Pavement, Asphalt Layer | Coating | Bitumen | Function | Reinforcement |

|---|---|---|---|---|---|

| HS Code | 701959000 | Length | 50-100m | Material | Fiberglass |

| Origin | China | Production Capacity | 1000000 Sqm Per Day | Specification | 3.95*100m/roll |

| Tensile Strength | 30-300kn/M | Usage | Asphalt Road,Asphalt Layer,Asphalt Pavement | ||

Product Description

Fiberglass geogrid is a high-strength structural grid manufactured from continuous glass fiber rovings coated with polymer binders (e.g., PVC, acrylic, or bitumen). Unlike flexible mesh fabrics, geogrids feature rigid, dimensionally stable apertures formed through warp-knitting or welding processes. The resulting lattice provides exceptional tensile strength (typically 50-400 kN/m) while maintaining chemical inertness and low elongation (<4%). Key specifications include aperture size (10-50mm), tensile modulus, and surface treatment compatibility.

Primary Applications

Road & Railway Base Stabilization:

Reinforce unbound aggregate layers in paved/unpaved roads

Reduce rutting in soft subgrades

Asphalt Pavement Reinforcement:

Anti-reflective crack interlayer in asphalt overlays

Minimize fatigue cracking in highways/airfields

Retaining Structures:

Reinforced soil walls and steep slopes (>45°)

Embankment Support:

Bridges transition zones over weak soils

Landfill & Erosion Control:

Base reinforcement for liner systems

Anchoring for erosion control mats

Performance Advantages

Ultra-High Tensile Strength: 3-5x stronger than polyester geogrids at equivalent strain

Zero Creep: Maintain load distribution under sustained tension

Chemical Resistance: Immune to soil alkalinity, hydrocarbons, and biological degradation

Temperature Resilience: Stable performance from -70°C to 230°C

Installation Efficiency: Pre-tensioned rolls deploy 40% faster than metal alternatives

Lifecycle Economy: 50+ year service life with no maintenance

Fiberglass Geogrid: Technical Q&A

Q1: How does fiberglass geogrid outperform traditional PP/PET geogrids in pavement applications?

A1: Fiberglass geogrids deliver 200% higher stiffness modulus (≥25 GPa) and near-zero creep deformation under sustained load. Unlike polymeric grids, they don’t suffer stress relaxation in high-temperature asphalt layers (>160°C), ensuring consistent reflective crack suppression for 15+ years.

Q2: What aperture geometry optimizes soil-aggregate interlock?

A2: Rectangular apertures (e.g., 25mm x 33mm) provide superior mechanical interlock vs. square grids. The 3:2 aspect ratio increases aggregate confinement by 60% while maintaining in-plane drainage. Optimal aperture size equals 1.5x the D50 particle size of compacted aggregate.

Q3: Can fiberglass geogrids replace steel reinforcement in MSE walls?

A3: Yes, when designed with ≥2% strain tolerance. Fiberglass grids reduce wall thickness by 30% vs. steel due to higher tensile strength per unit weight. Critical design parameters include peak/residual interface friction angles (≥34°) and connection strength (>80% of grid strength).

Q4: How is UV degradation prevented during installation?

A4: Polymer coatings (minimum 0.3mm PVC) provide 500+ hour UV resistance per ASTM D4355. For extended exposure, carbon-black modified coatings block 98% UV radiation. Post-installation and soil cover >150mm ensures permanent protection.

Q5: What quality certifications validate geogrid performance?

A5: Compliance with ISO 10319 (wide-width tensile test), ASTM D6637 (junction strength), and GRI GG7 (creep test) is mandatory. Leading manufacturers supply third-party verification of:

Long-term design strength (LDS) per EN ISO 20432

Alkaline resistance per ISO/TR 20432

Engineering Impact

Fiberglass geogrid transforms infrastructure durability through its synergy of mineral-strength tensile capacity and engineered aperture geometry. In asphalt reinforcement, it extends pavement service life by 8-12 years by reducing crack propagation rates by 70%. For embankments, it enables 3:1 slope construction on soils with CBR <1.0. The material’s electrochemical neutrality makes it indispensable in corrosive environments where steel reinforcements fail within 15 years. Specification requires rigorous analysis of aperture-soil interaction mechanics, but delivers unparalleled ROI through reduced aggregate thickness and extended maintenance cycles.

Recommended Products

Recently Viewed

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility

Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility Introduction to the basic parameters and applications of glass fiber mesh

Introduction to the basic parameters and applications of glass fiber mesh China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof

China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Contact Us

Jiangxi Ming Yang Glass Fiber Co., Ltd.