Welcome!

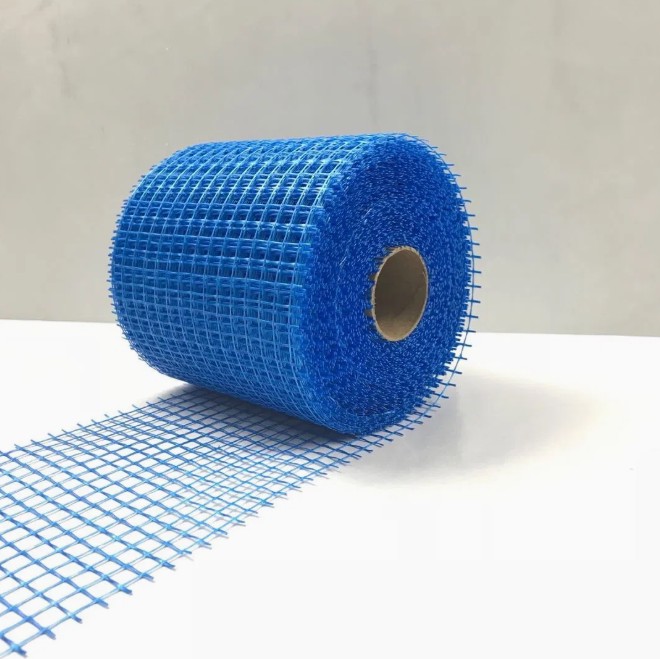

Introduction to the basic parameters and applications of glass fiber mesh

Basic Info

| Alkali Content | Medium | Model NO. | 5x5/4x4/3x3mm | Origin | China |

|---|---|---|---|---|---|

| Production Capacity | 1000000m2/Month | Specification | 45g-300g | Weave Type | Twill Woven |

Product Description

For over a decade, professionals in construction and renovation have relied on a hidden champion behind countless successful projects: fiberglass mesh. This versatile reinforcing material is the cornerstone of durability and resilience in modern building practices. But what exactly is it, and why should it be a key component in your next project? This comprehensive guide delves deep into the world of fiberglass mesh, exploring its properties, benefits, and the myriad of applications where it excels.

What is Fiberglass Mesh? The Fundamentals

Fiberglass mesh is a robust grid-like fabric woven from fiberglass yarns. These yarns are composed of incredibly fine glass fibers, which are twisted together and then coated with a special alkali-resistant dispersion. This coating is critical, as it protects the glass fibers from the corrosive effects of cement and plaster, ensuring long-term stability. The result is a strong, yet flexible, material that is lightweight, non-flammable, and resistant to mold, mildew, and chemical degradation. It is engineered to provide exceptional tensile strength, meaning it can withstand significant pulling forces without breaking or distorting.

Key Advantages: Why Choose Fiberglass Mesh?

The decision to integrate fiberglass mesh into a project is driven by its numerous performance-enhancing advantages. Its primary benefit is its unparalleled ability to prevent cracks. When embedded in a base layer of plaster, stucco, or adhesive, it creates a continuous reinforcement that distributes stress across a wider area. This drastically reduces the likelihood of cracks forming due to building settlement, thermal expansion, or vibrational stresses. Furthermore, its flexibility allows it to conform to curved or irregular surfaces without compromising its structural integrity.

Another significant advantage is its durability. Unlike metal lath, fiberglass mesh will never rust or corrode, guaranteeing the integrity of the wall system for the life of the building. It is also incredibly easy to work with. It can be quickly cut to size with a utility knife and pressed into fresh compound, speeding up installation time and reducing labor costs. Its lightweight nature makes it easy to handle and transport, contributing to a more efficient worksite.

Diverse Applications: Where is Fiberglass Mesh Used?

The utility of fiberglass mesh spans a wide range of industries and applications. In exterior insulation and finish systems (EIFS), it is an indispensable component, providing the necessary reinforcement within the base coat. For interior drywall installations, it is the preferred choice for taping and sealing joints between plasterboard panels, creating a seamless and strong surface for painting or wallpapering.

It is also extensively used in tile and stone installations. When used as an underlayment or embedded in tile adhesive on crack-prone substrates, it prevents movement from transferring to the tiles, preventing costly failures. Beyond walls, it finds purpose in floor screeding, roof repair, and even in fabricating composite materials for industries beyond construction, such as marine and automotive.

Selecting the Right Fiberglass Mesh for Your Project

Not all fiberglass meshes are created equal. Selection depends heavily on the specific application. Key differentiating factors include mesh density (weight per unit area), tensile strength, and the quality of the coating. For heavy-duty exterior work or structural reinforcement, a heavier, high-tensile mesh is required. For standard drywall taping, a lighter-weight mesh is perfectly adequate. Always ensure the product is explicitly rated as alkali-resistant to avoid premature deterioration in cementitious applications.

Fiberglass Mesh Q&A: Answering Your Top Questions

Q1: How does fiberglass mesh compare to traditional paper or metal tape for drywall?

A1: Fiberglass mesh is superior to paper tape in several ways. It is self-adhesive, easier to handle, and less prone to bubbling. Its inherent strength provides better crack resistance. Compared to metal tape, it is lighter, easier to cut, and completely immune to rust, making it a more durable and user-friendly option for most applications.

Q2: Can fiberglass mesh be used for repairing large cracks?

A2: Absolutely. For repairing existing cracks, especially hairline or stair-step cracks in walls, fiberglass mesh is an excellent solution. The cracked area should be V-cut to create a groove, which is then filled with compound. A piece of mesh is embedded over the fresh compound, bridging the crack and preventing it from reappearing on the finished surface.

Q3: Is fiberglass mesh waterproof?

A3: While the fiberglass strands themselves are impervious to water, the mesh fabric is not a standalone waterproofing barrier. It is water-resistant and will not degrade when wet. However, for areas requiring waterproofing, a dedicated waterproofing membrane must be used in conjunction with or instead of the mesh.

Q4: How do I properly install fiberglass mesh?

A4: For drywall, apply the self-adhesive mesh directly over the joint, pressing it firmly into place. For embedded applications, apply a layer of your base coat material (e.g., plaster, thinset), press the mesh into it firmly, and then completely cover it with a second layer of the material, ensuring full encapsulation.

Q5: What safety precautions should I take when handling fiberglass mesh?

A5: While modern meshes are designed to be safe, it is always advisable to wear gloves to prevent minor irritation from glass fibers. Safety glasses can protect your eyes from any loose particles when unrolling and cutting the material.

Q6: Can it be used on exterior surfaces?

A6: Yes, but it is imperative to use a mesh specifically manufactured and rated for exterior use. These meshes have a heavier, more durable coating to withstand UV exposure and harsh weather conditions before being covered.

Recommended Products

Recently Viewed

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility

Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility Introduction to the basic parameters and applications of glass fiber mesh

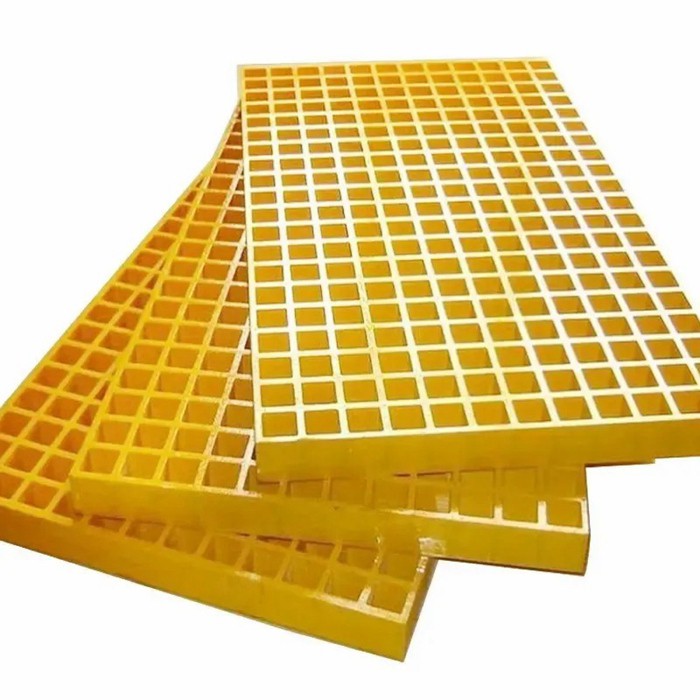

Introduction to the basic parameters and applications of glass fiber mesh China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof

China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Contact Us

Jiangxi Ming Yang Glass Fiber Co., Ltd.