Welcome!

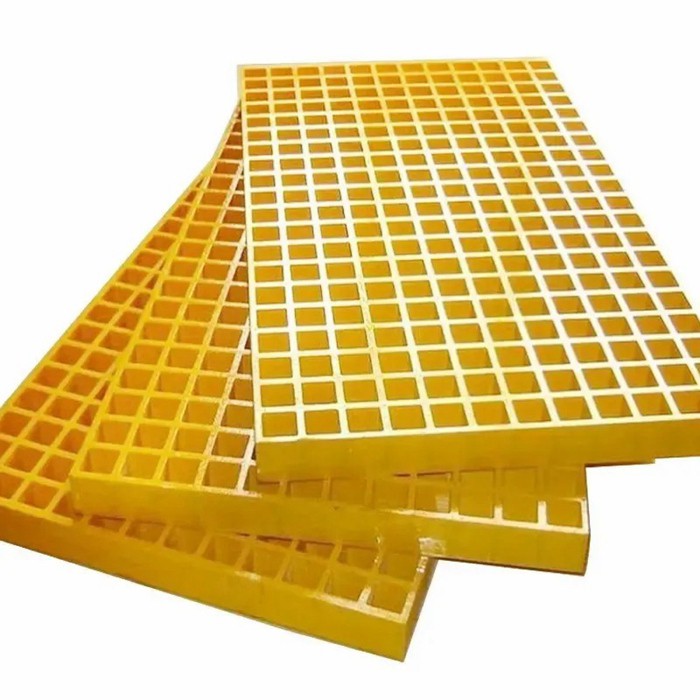

China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof

Basic Info

| Application | Wall Materials, Heat Insulation Materials | Fiberglass Type | C-Glass | HS Code | 7019902190 |

|---|---|---|---|---|---|

| Model NO. | 5x5/4x4/3x3mm | Origin | China | Specification | 45g-300g |

| Trademark | Customized | ||||

Product Description

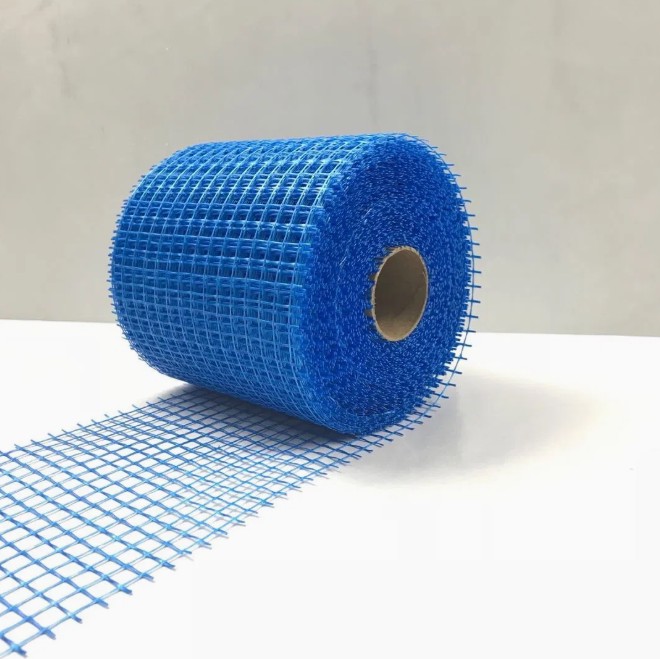

In the world of building and renovation, true success often lies in the materials you don't see. Fiberglass mesh is one such foundational component, a critical player in ensuring the longevity, strength, and finish of countless projects. This engineered fabric is far more than just a simple grid; it's a sophisticated solution designed to combat some of the most common and costly issues in construction. This guide explores the essential role of fiberglass mesh, detailing its characteristics, undeniable benefits, and the practical know-how for its application.

Beyond the Grid: Understanding Fiberglass Mesh Fabric

At its core, fiberglass mesh is a web of strands meticulously woven from fiberglass yarn. These yarns are themselves composed of numerous continuous glass filaments, offering exceptional inherent strength. The weaving process creates a stable grid pattern, which is then uniformly coated with a specially formulated alkali-resistant treatment. This coating is not merely a surface layer; it is a vital protective barrier that shields the glass fibers from the high pH levels found in cement, plaster, and other masonry materials. Without it, the mesh would quickly succumb to degradation. The final product is a remarkably strong, dimensionally stable, and flexible material that is also impervious to moisture, rot, and fire.

The Compelling Benefits: Why This Material is a Industry Staple

The widespread adoption of fiberglass mesh is driven by a powerful set of advantages that directly translate to better project outcomes and cost savings. Its foremost benefit is its exceptional crack prevention capability. By creating a continuous reinforcing layer within a substrate, it absorbs and distributes mechanical stresses caused by structural movement, thermal expansion, and vibration. This effectively controls hairline cracking, preserving a flawless surface finish.

Durability is another cornerstone of its value proposition. As a non-metallic material, it completely eliminates the risk of rust stains bleeding through finishes, a common failure point with steel lath. This guarantees the long-term aesthetic and structural integrity of a wall or floor system. From an installer's perspective, its ease of use is a significant productivity booster. It is lightweight, easy to cut and shape, and simplifies the process of reinforcing seams and corners. This efficiency reduces labor time and minimizes material waste.

A Material for Every Trade: Diverse Applications Across Industries

The versatility of fiberglass mesh allows it to serve a multitude of purposes. In exterior wall systems, such as Exterior Insulation and Finish Systems (EIFS) and synthetic stucco, it is embedded in the base coat to provide crucial reinforcement and impact resistance. For interior walls, it is the modern standard for taping and finishing drywall joints, creating a smooth, monolithic surface that is stronger than the panels themselves.

Tile and stone installers rely on it as a crack isolation membrane, preventing cracks in concrete subfloors or walls from telegraphing through to the finished tilework. Its uses extend to floor screeding, where it reinforces the screed to prevent cracking, and to roof repairs for stabilizing areas before applying new coatings. Beyond traditional construction, its properties are utilized in the manufacturing of composites and in industrial settings for filtration and screening.

Selecting the Correct Mesh: A Matter of Specification

Choosing the appropriate fiberglass mesh is critical for performance. The key is to match the product's properties to the demands of the application. Important specifications include mesh weight (often in grams per square meter), tensile strength (in both warp and weft directions), and the quality of the coating. A heavy-duty mesh with high tensile strength is mandatory for exterior facade work, while a standard-weight mesh is sufficient for interior drywall seams. Always verify that the product is explicitly rated for alkaline environments to ensure long-term performance.

Q&A:

Q1: Is fiberglass mesh better than paper tape for drywall?

A1: Many professionals prefer fiberglass mesh for its ease of use and consistent performance. Its self-adhesive backing makes application quick, and it is less prone to bubbling or peeling compared to paper tape. It also provides superior resistance against cracking due to its high tensile strength.

Q2: How do I handle corners when using fiberglass mesh?

A2: For both inside and outside corners, pre-folded rolls of mesh are available to ensure a sharp, clean, and strong finish. These pre-formed pieces are pressed into the applied compound, ensuring full coverage and reinforcement in these high-stress areas.

Q3: Can I use any fiberglass mesh for outdoor projects?

A3: No. Only mesh that is specifically manufactured and labeled for exterior use should be employed outdoors. Exterior-grade mesh has a heavier, more resilient coating to withstand environmental exposure and the alkaline nature of cement-based renders during the curing process.

Q4: How is fiberglass mesh installed under tile?

A4: For crack isolation, a layer of thin-set mortar is troweled onto the substrate. The mesh is then rolled out and embedded into the mortar, ensuring full contact. A second layer of mortar is applied on top, fully encapsulating the mesh before the tile is set.

Q5: Is fiberglass mesh resistant to mold growth?

A5: Yes, one of its inherent properties is that it does not support mold or mildew growth. This makes it an excellent choice for applications in areas prone to moisture, such as bathrooms, kitchens, and basements, helping to maintain healthier indoor air quality.

In summary, fiberglass mesh is an indispensable innovation in construction materials. It provides a simple yet profoundly effective method for adding strength, preventing damage, and ensuring the longevity of both structural and finishing elements. By selecting the right type of mesh for the job and installing it correctly, contractors and DIYers can achieve professional, durable results that stand the test of time.

Recommended Products

Recently Viewed

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility

Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility Introduction to the basic parameters and applications of glass fiber mesh

Introduction to the basic parameters and applications of glass fiber mesh China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof

China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Contact Us

Jiangxi Ming Yang Glass Fiber Co., Ltd.