Welcome!

Unlocking the Potential of Plastic Granulator Machines

Basic Info

| Automation | Automatic | Certification | ISO9001:2008 | Computerized | Non-Computerized |

|---|---|---|---|---|---|

| Condition | New | Customized | Customized | Electromagnetic Heater | Electromagnetic Heater |

| Inverter | Inverter | Model NO. | 125mm | Origin | China |

| Production Capacity | 999 Sets Per Year | Specification | 125mm screw | Transport Package | Plywood Packing |

Product Description

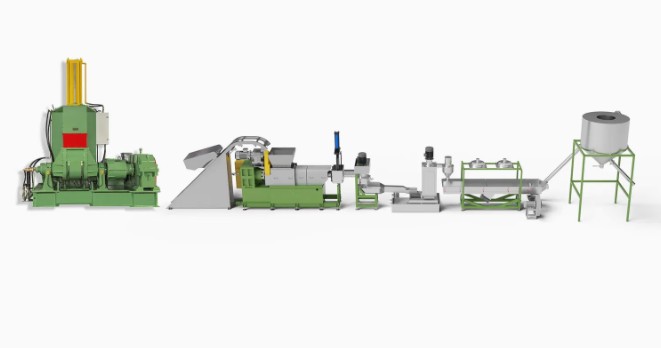

In the ever-evolving landscape of recycling and manufacturing, plastic granulator machines stand out as vital tools in transforming waste into reusable materials. Ideal for a variety of industries such as recycling, packaging, and injection molding, these machines play a critical role in enhancing efficiency and sustainability. Let’s explore the key features, advantages, and applications of plastic granulator machines in detail.

Key Features

Plastic granulator machines are designed with several essential features that optimize their performance. The heart of these machines is their robust cutting system, which typically incorporates sharp blades configured to handle different types of plastics including polyethylene, polypropylene, and polystyrene. The size of granules can be tailored to specific requirements, allowing operators to produce anything from fine powders to coarse granules.

Another significant feature is the adjustable feed rate, which ensures consistent material processing. Additionally, many modern models include advanced controls for temperature regulation, providing operators with the ability to manage the melting and cooling process effectively, thus preventing material degradation. The user-friendly interface often simplifies operation, making it accessible even to those with limited technical expertise.

Significant Advantages

The advantages of employing plastic granulator machines are multifaceted. Firstly, they contribute significantly to waste reduction. By effectively recycling plastic waste, these machines help industries comply with environmental regulations and reduce operational costs associated with raw material purchase.

Furthermore, plastic granulator machines streamline production processes. They provide a reliable means of preparing materials for secondary processes like extrusion or injection molding, thereby enhancing manufacturing efficiency. This not only reduces the time needed between production stages but also heightens the quality of final products by ensuring a consistent feedstock.

Moreover, many machines are designed with energy efficiency in mind. Advanced technologies allow for reduced power consumption while maintaining high-performance standards, ultimately leading to lower operating costs and a smaller carbon footprint.

Applications Across Industries

Plastic granulator machines find applications in a broad spectrum of industries. In the recycling sector, they play a pivotal role in the reprocessing of post-consumer plastics, transforming waste products into valuable raw materials. This process supports a circular economy, where waste materials are continuously repurposed.

In manufacturing, these machines are indispensable for preparing raw materials for production lines. They are commonly utilized in the production of plastic components in automotive, electronics, and consumer goods industries. The granulated plastic can be mixed with additives or colorants before being fed into an extruder or injection molding machine, ensuring that the final products meet specific aesthetic and functional characteristics.

Additionally, plastic granulator machines serve industries involved in film and sheet production, offering efficient granulation of production waste that can be reused in the same or new products. Their versatility truly makes them an essential asset across various sectors.

Conclusion

In summary, plastic granulator machines are integral to modern recycling and manufacturing processes. With their advanced features, significant advantages, and broad applications, they embody a sustainable solution for managing plastic waste and enhancing production efficiency. Investing in a quality plastic granulator machine not only bolsters operational capabilities but also contributes to a greener and more sustainable future for the plastic industry. If you're looking to elevate your recycling efforts or improve your manufacturing process, consider the transformative potential of plastic granulator machines and their role in shaping a more sustainable world.

Recommended Products

Recently Viewed

Maximize Recycling ROI: High-Efficiency Plastic Crushing & Pelletizing Machine for Sustainable Production

Maximize Recycling ROI: High-Efficiency Plastic Crushing & Pelletizing Machine for Sustainable Production Low-priced new products launched - Waste Plastic Granulators

Low-priced new products launched - Waste Plastic Granulators Unleashing Efficiency: The Power of Plastic Granulator Machines

Unleashing Efficiency: The Power of Plastic Granulator Machines Revolutionizing Waste Management: The Power of Plastic Granulator Machines

Revolutionizing Waste Management: The Power of Plastic Granulator Machines Unlocking the Potential of Plastic Granulator Machines

Unlocking the Potential of Plastic Granulator Machines

Contact Us

Jiangsu Aceretech Machinery Co., Ltd.